Preparation method of transparent conducting material based on 3D printing technology

A transparent conductive material, 3D printing technology, used in cable/conductor manufacturing, circuits, electrical components, etc., can solve the problems of long operation cycle, expensive equipment, poor adhesion between film and substrate, etc., to overcome poor adhesion, thickness and Precisely controllable width, good light transmission and conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the above-mentioned features and advantages of the present invention more comprehensible, the following specific embodiments are described in detail in conjunction with the accompanying drawings.

[0020] The present invention will be further described in detail through specific examples below.

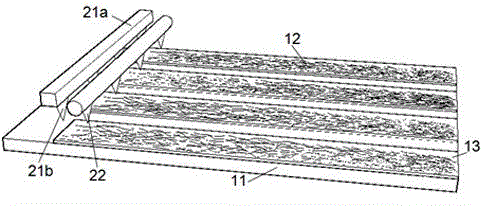

[0021] refer to figure 1 Schematic diagram for the preparation of strip-shaped transparent conductive electrodes by 3D printing technology in the form of ultraviolet exposure.

[0022] The strip-shaped transparent conductive electrode includes 11 glass substrates, 12 multi-walled carbon nanotubes and 13 photosensitive resin. The device applied by the 3D printing technology includes 21a liquid chamber, 22b 3D printing head and 22 laser heads.

[0023] The 22b 3D printing head is an atomizing pneumatic nozzle, and it is a linear array. The 22 laser heads are also of linear array type.

[0024] First configure the solution for 3D printing technology in the for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com