Perovskite thin-film solar cell with three-dimensional ordered mesopore support layer

A solar cell, three-dimensional orderly technology, applied in the manufacture/processing of organic semiconductor devices, circuits, photovoltaic power generation, etc., can solve the problem of poor crystallization speed of perovskite films, poor film-forming properties, poor structural stability of solar cells, and obstacles to effective electron transmission and other issues, to achieve good electron transport ability, photoelectric conversion efficiency improvement, electron-hole recombination suppression effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

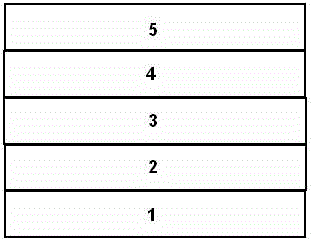

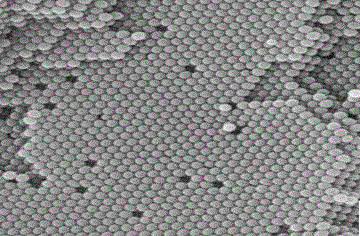

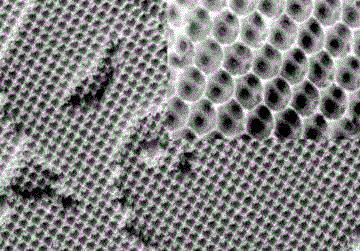

[0032] A perovskite thin-film solar cell with a three-dimensionally ordered mesoporous scaffold layer, such as figure 1 As shown, a laminated structure is composed of a transparent conductive substrate 1, a dense layer 2, a three-dimensionally ordered mesoporous scaffold layer, and a perovskite light-absorbing layer 3 filled therein, a hole transport layer 4, and a counter electrode layer 5. The transparent conductive substrate 1 is FTO conductive glass; the dense layer 2 is TiO 2 Thin film, thickness is 50nm; Three-dimensional ordered mesoporous support layer is the titanium dioxide (3DOM TiO 2 ), the pore size of the three-dimensional ordered mesoporous scaffold layer is 50nm, prepared from water-soluble colloidal crystal template microspheres with a diameter of 50nm, and the film thickness is 500nm; the perovskite light-absorbing layer is CH 3 NH 3 PB 3 The hole transport layer is 2,2',7,7'-tetrakis[N,N-diamino]-9,9'-spirobifluorene Spiro-OMETAD; the counter electrode la...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com