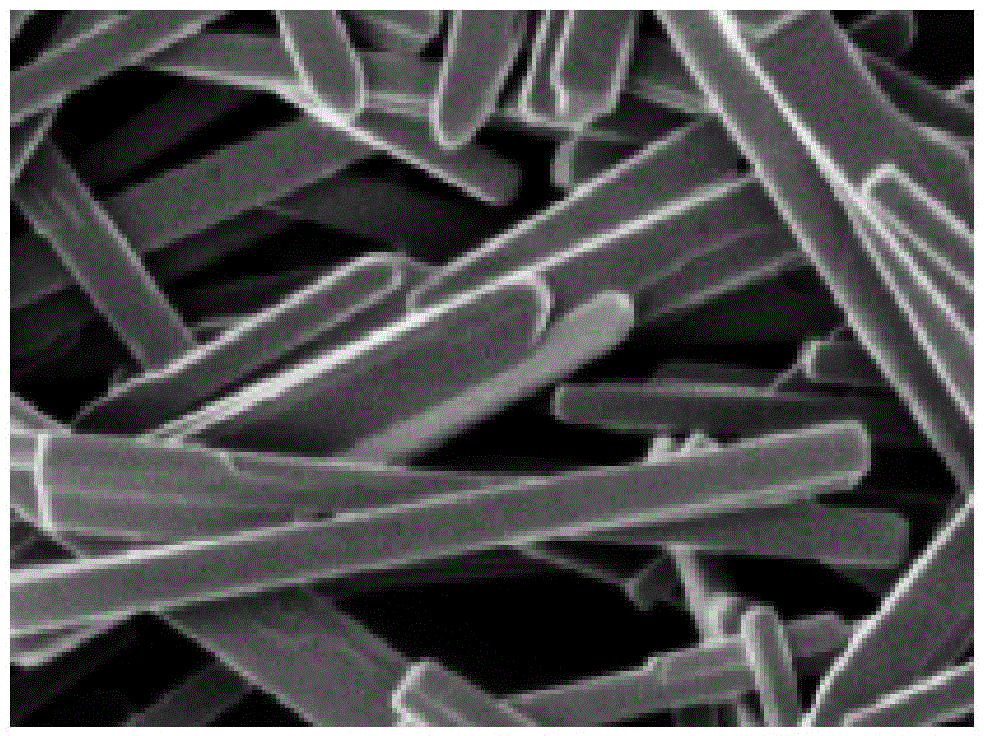

Nano rod-shaped nickel-lithium manganate cathode material and preparation method thereof

A positive electrode material, lithium nickel manganese oxide technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of poor cycle stability of lithium-ion batteries, achieve improved cycle stability, reduce Side reaction, effect of structure stabilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] On the one hand, an embodiment of the present invention provides a method for preparing a nanorod-shaped lithium nickel manganese oxide positive electrode material, the method comprising:

[0029] Step 101, according to the chemical formula LiNi 0.5 mn 1.5 o 4 The substance ratio of each element is dissolved in distilled water with a predetermined amount of manganese salt and persulfide, and a mixed solution is obtained after stirring evenly.

[0030] Step 102, performing airtight heat treatment on the mixed solution obtained in step 101 to obtain MnO 2 precipitation, and the MnO 2 The precipitate is washed and dried to obtain MnO 2 Nano stave.

[0031] Step 103, the MnO obtained in step 102 2 Nanorods and nickel salts are mixed in a polar solvent and dispersed ultrasonically, and then an alkaline solution is added dropwise to the polar solvent to obtain nickel-manganese hydroxide precipitation, and the nickel-manganese hydroxide precipitation Washing and drying ...

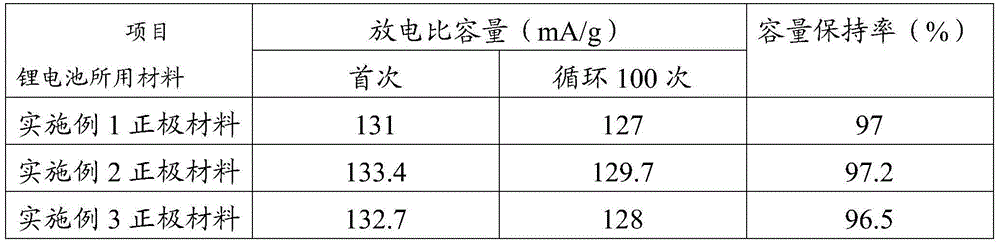

Embodiment 1

[0049] This embodiment provides a nanorod-shaped lithium nickel manganese oxide positive electrode material, the preparation method of which comprises the following steps:

[0050] According to the chemical formula LiNi 0.5 mn 1.5 o 4 For the ratio of substances of each element, 3.38g of manganese sulfate monohydrate and 4.76g of sodium persulfate were dissolved in 100ml of distilled water, and stirred evenly by magnetic force to obtain a mixed solution with a concentration of 0.02mol / L.

[0051] Carry out airtight heat treatment on the mixed solution obtained above, the heating time is 15h, and the heating temperature is 180°C. After the reaction is complete, MnO 2 Precipitate, after filtering and washing the precipitate, heat and dry it in the air at 100°C for 6h to obtain MnO 2 Nano stave.

[0052] 0.87g MnO 2 Ultrasonic dispersion of nanorods and 7.89g nickel sulfate hexahydrate in 200ml ethanol solution, then in this ethanol solution, dropwise adding 100ml concentrat...

Embodiment 2

[0056] This embodiment provides a nanorod-shaped lithium nickel manganese oxide positive electrode material, the preparation method of which comprises the following steps:

[0057] According to the chemical formula LiNi 0.5 mn 1.5 o 4 For the ratio of substances of each element, 3.78g of manganese chloride and 8.11g of potassium persulfate were dissolved in 300ml of distilled water, and magnetically stirred to mix evenly to obtain a mixed solution with a concentration of 0.01mol / L.

[0058] Carry out airtight heat treatment on the mixed solution obtained above, the heating time is 8h, and the heating temperature is 130°C. After the reaction is complete, MnO 2 Precipitate, after filtering and washing the precipitate, heat and dry it in the air at 80°C for 12h to obtain MnO 2 Nano stave.

[0059] 0.87g MnO 2 Nano-rods and 3.91g nickel chloride are ultrasonically dispersed in 200ml aqueous solution, and then in this aqueous solution, dripping 120ml concentration is the potas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap