ZSM-35 molecular sieve preparation method

A technology of ZSM-35 and molecular sieves, which is applied in the field of preparation of ZSM-35 molecular sieves, can solve the problems of increasing the difficulty of molecular sieve post-treatment, increasing production equipment, and increasing production costs, so as to reduce aggregation and carbon deposition, simplify production processes, The effect of improving catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

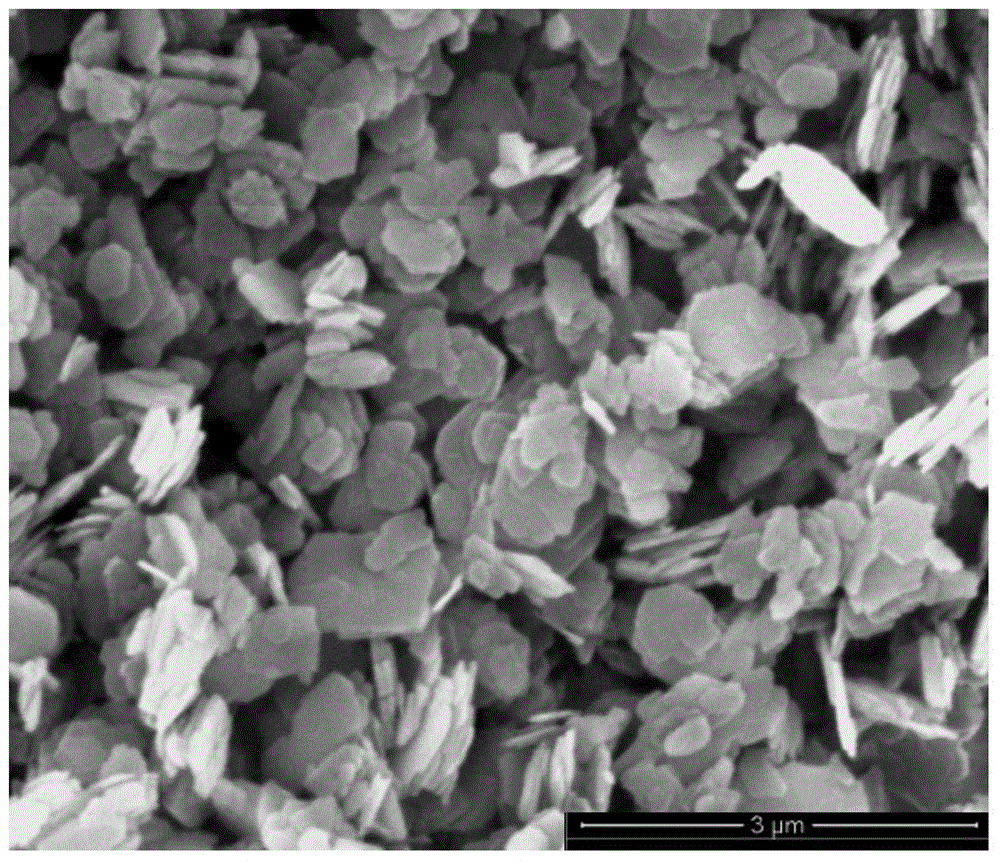

[0033] Step A: First, add 83 grams of aluminum sulfate (analytical pure, content greater than 99.5%) into 235 ml of deionized water under stirring at 25°C, and stir for 40 minutes. After the aluminum sulfate is completely dissolved, add 675 grams of silica sol (silica sol with a SiO2 content of 22.2%) and stir for 1 hour to form a mixed solution of silica and aluminum. 3 g of ZSM-35 seed crystals with a diameter of 300-800 nm and a thickness of less than 100 nm were added to the above mixed solution, and stirred at 80 rpm for 2 hours.

[0034] Step B: to the above-mentioned aluminum sulfate, silica sol (SiO 2 Content is 22.2% silica sol) and the mixed solution formed by the ZSM-35 molecular sieve seed crystal, slowly add 0.5mol / L sodium hydroxide aqueous solution 100ml, fully stir to form a colloidal solution. Add 75ml of cyclohexylamine as a template and 1.5g of the ZSM-35 seed crystal, and stir evenly to prepare a reaction mixture. This mixture has the following molar comp...

Embodiment 2

[0038] The steps are the same as in Example 1, except that the initial stirring temperature in step A is 50°C, the mass of the added ZSM-35 seed crystals is 5g, and the stirring condition is 95 rpm and stirring for 1.5 hours ; In step B, the quality of the ZSM-35 seed crystal added is 2.5g; The total weight of the ZSM-35 seed crystal added is based on SiO 2 5.0wt% of the total weight of the silicon source, the crystallization time in step C is 40h.

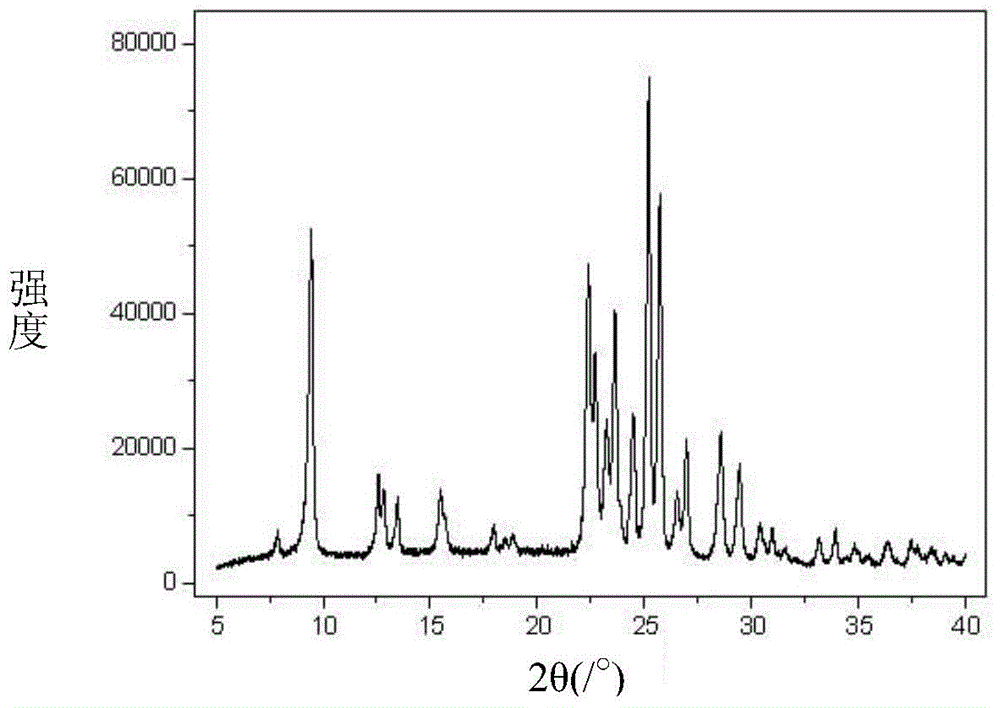

[0039] The molecular sieve obtained above is measured by X-ray diffraction and SEM, and it is confirmed that the molecular sieve synthesized by this method has a FER structure, is a ZSM-35 molecular sieve, and its crystallinity is 88%, and its grain diameter is 300~700nm, and the thickness is less than 100nm.

Embodiment 3

[0041] Step is the same as Example 1, except that the initial stirring temperature in step A is 40°C, the added silica sol (SiO 2 Silica sol with a content of 22.2%) is 337 grams, the quality of the added ZSM-35 seed crystal is 1.5 g, and the stirring condition is 95 rpm stirring for 1.5 hours; in step B, the added The mass of the ZSM-35 seed crystal is 0.75 g, and the mixture has the following molar composition: OH - : Al 2 o 3 : SiO 2 :R:H 2 O=0.4:0.1:1:0.6:27; in Step C, the temperature was raised to 200° C. under the stirring condition of 85 rpm, and the constant temperature crystallization was carried out for 40 h.

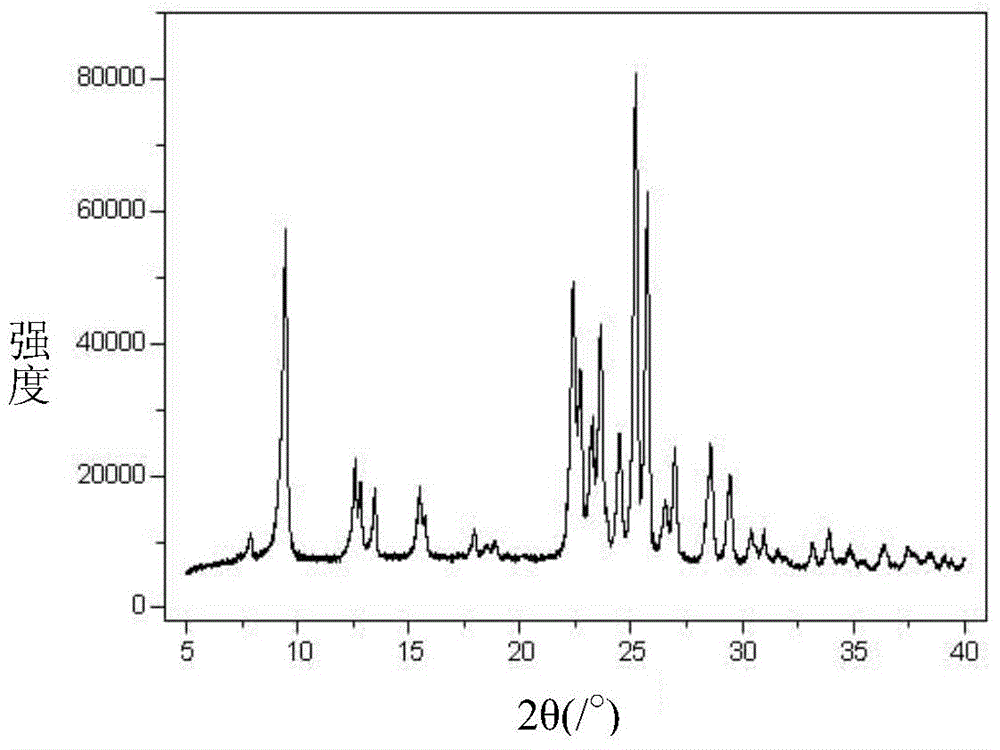

[0042] The molecular sieve obtained above is measured by X-ray diffraction and SEM, and it is confirmed that the molecular sieve synthesized by this method has a FER structure, is a ZSM-35 molecular sieve, and its crystallinity is 89%, and its grain diameter is 200~600nm, and the thickness is less than 100nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Grain diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Grain diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com