Polymer-based electromagnetic shielding material based on carbon fiber and graphene and preparation method of polymer-based electromagnetic shielding material

An electromagnetic shielding material, graphene technology, applied in the field of polymer-based electromagnetic shielding materials and its preparation, can solve the problem that conductive carbon black and carbon fiber cannot form a transport network, the interface adhesion of composite materials is low, and it is difficult to make complex shapes Products and other issues, to achieve good electromagnetic shielding effect, low cost, prevent curl or wrinkle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

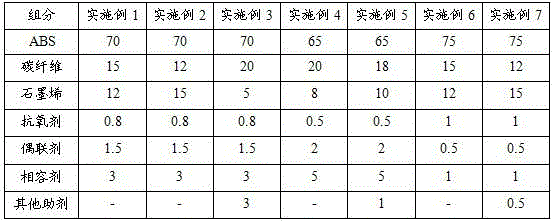

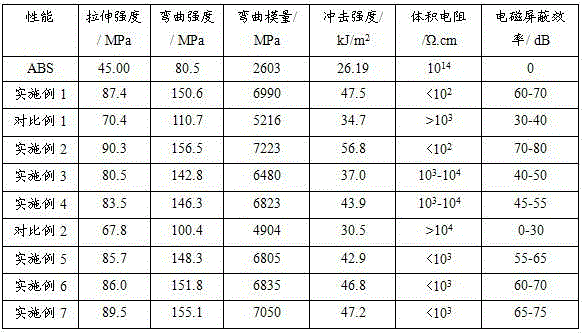

Examples

Embodiment 1

[0032] (1) Add chopped carbon fibers into a mixed solution of concentrated sulfuric acid and concentrated nitric acid (volume ratio 3:1) at a mass ratio of 1:75, ultrasonically disperse for 2.5 hours, filter with suction, wash, and dry to obtain acidified carbon fibers.

[0033](2) Dissolve 1.5 parts of isopropyl tris (dioctyl pyrophosphate acyloxy) titanate in 225 parts of dichloroethane to make a solution, add 15 parts of the above-mentioned acidified carbon fiber, 12 parts of graphene, and process under ultrasonic and stirred for 2 hours to obtain a suspension; 70 parts of ABS were dissolved in 700 parts of dichloroethane, added to the above suspension, treated with ultrasonic waves and stirred for 2 hours, and the resulting mixture was dried at 70°C for 16 hours to remove dichloro ethane to obtain a powder mixture.

[0034] (3) Mix the mixture powder obtained in step (2), 0.8 parts of antioxidant 1010, and 3 parts of ABS-g-MAH evenly, and then send them into a twin-screw e...

Embodiment 2

[0037] (1) Add chopped carbon fibers into a mixed solution of concentrated sulfuric acid and concentrated nitric acid (volume ratio 3:1) at a mass ratio of 1:75, ultrasonically disperse for 2.5 hours, filter with suction, wash, and dry to obtain acidified carbon fibers.

[0038] (2) Dissolve 1.5 parts of isopropyl tris (dioctyl pyrophosphate acyloxy) titanate in 225 parts of dichloroethane to make a solution, add 12 parts of the above-mentioned acidified carbon fiber, 15 parts of graphene, and treat under ultrasonic and stirred for 2 hours to obtain a suspension; 70 parts of ABS were dissolved in 700 parts of dichloroethane, added to the above suspension, treated under ultrasonic waves and stirred for 2 hours, and the resulting mixture was dried at 70°C for 16 hours to remove dichloromethane. Chloroethane, the mixture powder was obtained.

[0039] (3) Mix the mixture powder obtained in step (2), 0.8 parts of antioxidant 1076, and 3 parts of ABS-g-MAH evenly, and then send them...

Embodiment 3

[0042] (1) Add chopped carbon fibers into a mixed solution of concentrated sulfuric acid and concentrated nitric acid (volume ratio 3:1) at a mass ratio of 1:75, ultrasonically disperse for 2.5 hours, filter with suction, wash, and dry to obtain acidified carbon fibers.

[0043] (2) Dissolve 1.5 parts of isopropyl tris (dioctyl pyrophosphate acyloxy) titanate in 225 parts of dichloroethane to make a solution, add 20 parts of the above-mentioned acidified carbon fiber, 5 parts of graphene, and treat under ultrasonic and stirred for 2 hours to obtain a suspension; 70 parts of ABS were dissolved in 700 parts of dichloroethane, added to the above suspension, treated with ultrasonic waves and stirred for 2 hours, and the resulting mixture was dried at 70°C for 16 hours to remove dichloro ethane to obtain a powder mixture.

[0044] (3) Mix the mixture powder obtained in step (2), 0.8 parts of antioxidant 1098, 3 parts of ABS-g-MAH, and 5 parts of acrylonitrile-styrene-acrylate copol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com