Preparation method of methacryloxyethyltrimethyl ammonium chloride based anionic dye absorbent

A technology of methacryloyloxyethyltrimethylammonium chloride and anionic dyes, applied in chemical instruments and methods, adsorption water/sewage treatment, water pollutants, etc., can solve the problem of poor adsorption capacity, many raw materials, and water quality Secondary pollution and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

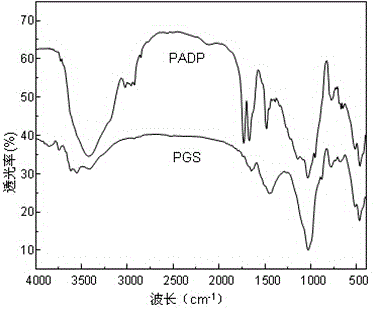

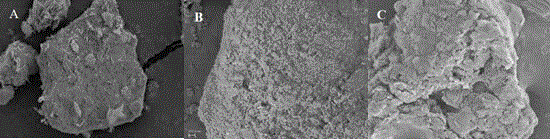

[0025] 1. Acidizing treatment of palygorskite clay: add a certain amount of palygorskite clay ore into a 1000 mL beaker, add water to 600 mL, and mechanically stir (1000 rpm) for 8 h. The obtained suspension was diluted with water, and after standing for a period of time, the supernatant liquid and the bottom sand layer were poured out, the middle layer mud suspension was washed three times, dried, pulverized, acidified with 1 M hydrochloric acid and washed with water until neutral, dried and pulverized , passed through a 200-mesh sieve to obtain acidified palygorskite clay (PGS).

[0026] 2. Preparation of composite adsorbent: 7.5 g of acrylic acid amine (AM) and 5 ml of deionized water were added to a three-necked flask, and after mechanical stirring for 10 min at room temperature, 0.75 g of PGS was added, and rapid stirring was performed ultrasonically for 30 min; Slowly add 7.5 g of methacryloyloxyethyltrimethylammonium chloride (DMC) dropwise to the system, and add 0.167 ...

Embodiment 2

[0029] 1. Same as Example 1.

[0030] 2. Preparation of composite adsorbent: 7.5 g of acrylic acid amine (AM) and 3 ml of deionized water were added to a three-necked flask, and after mechanical stirring for 10 min at room temperature, 0.3 g of PGS was added, and sonicated for 30 min with rapid stirring; Slowly add 7.5 g of methacryloyloxyethyltrimethylammonium chloride (DMC) dropwise to the system, and add 0.125 g of cross-linking agent N,N'-methylenebisacrylamide (MBA), continue to stir for 30 min, add 0.075 g of initiator ammonium persulfate, heat up to 75 °C, slowly stir until the polymer is formed, stop stirring, and continue the reaction for 2 h. The product is cut into pieces, washed three times with absolute ethanol (to neutrality), and dried at 75 °C to constant weight. The product is crushed, ground, passed through a 90-160 mesh sieve, and dried.

[0031] 3. Adsorption performance for anions: After testing, the adsorption capacity of the adsorbent for methyl orange ...

Embodiment 3

[0033] 1. Same as Example 1.

[0034]2. Preparation of composite adsorbent: 7.5 g of acrylic acid amine (AM) and 5 ml of deionized water were added to a three-necked flask, and after mechanical stirring for 10 min at room temperature, 2.25 g of PGS was added, and sonication was rapidly stirred for 30 min; Slowly add 22.5 g of methacryloyloxyethyltrimethylammonium chloride (DMC) dropwise to the system, and add 0.5 g of cross-linking agent N,N'-methylenebisacrylamide (MBA), continue to stir for 30 min, add 0.28125 g initiator ammonium persulfate, heat up to 75 °C, slowly stir until the polymer is formed, stop stirring, and continue the reaction for 2 h. The product is cut into pieces, washed three times with absolute ethanol (to neutrality), and dried at 75 °C to constant weight. The product is crushed, ground, passed through a 90-160 mesh sieve, and dried.

[0035] 3. Adsorption performance for anions: After testing, the adsorption capacity of the adsorbent for methyl orange i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com