Ordered mesoporous carbon material loaded platinum catalyst and application thereof to catalytic hydrogenation of aromatic nitro compound

A platinum catalyst and mesoporous carbon technology, which is applied in the application field of chemical catalytic materials, can solve the problems that the application of ordered mesoporous carbon materials is rarely reported, and achieve the effects of excellent catalytic performance, improved conversion rate and high stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] According to the literature Journal of the American Chemical Society 122 (2000) 10712, the ordered mesoporous carbon material CMK-3 was synthesized. Specifically include the following steps:

[0038] a, under 313K, 8.0g P123 (its molecular formula is EO 20 PO 70 EO 20 , the average molecular weight is 5800) dissolved in 60g deionized water and 240g 2mol / L hydrochloric acid mixture, after stirring to obtain a clear solution, 17.0g tetraethyl orthosilicate (TEOS) was added dropwise at one time; after stirring for 24 hours, the mixture was Aged at 373K for 24 hours; cooled in the air, filtered with suction, washed with a large amount of ethanol and deionized water, dried and roasted at 823K in a muffle furnace for 6 hours to obtain the ordered mesoporous silicon material SBA-15;

[0039] b. Weigh 6g of sucrose, 0.7g of concentrated sulfuric acid, and 30g of deionized water, mix them, and stir to obtain a clear solution, pour it into 5g of SBA-15 weighed in advance, stir...

Embodiment 2

[0042] a, using the ordered mesoporous carbon material CMK-3 obtained in Example 1 as a carrier, dropwise add an aqueous solution of chloroplatinic acid in the carrier, the weight ratio of its metal platinum to the carrier is 1: 19, evaporate to dryness after stirring for 6 hours solvent, and then dried at 373K in an oven for 12 hours to obtain an ordered mesoporous carbon material-supported platinum catalyst precursor;

[0043] b. The catalyst precursor obtained above was refluxed in 368K sodium formate aqueous solution for 2 hours to obtain the reduced catalyst, wherein the molar ratio of sodium formate to platinum content in the catalyst precursor was 10:1;

[0044] c. The above-mentioned reduced catalyst was filtered, washed with a large amount of deionized water, and dried at 373K for 12 hours to obtain an ordered mesoporous carbon material-supported platinum catalyst.

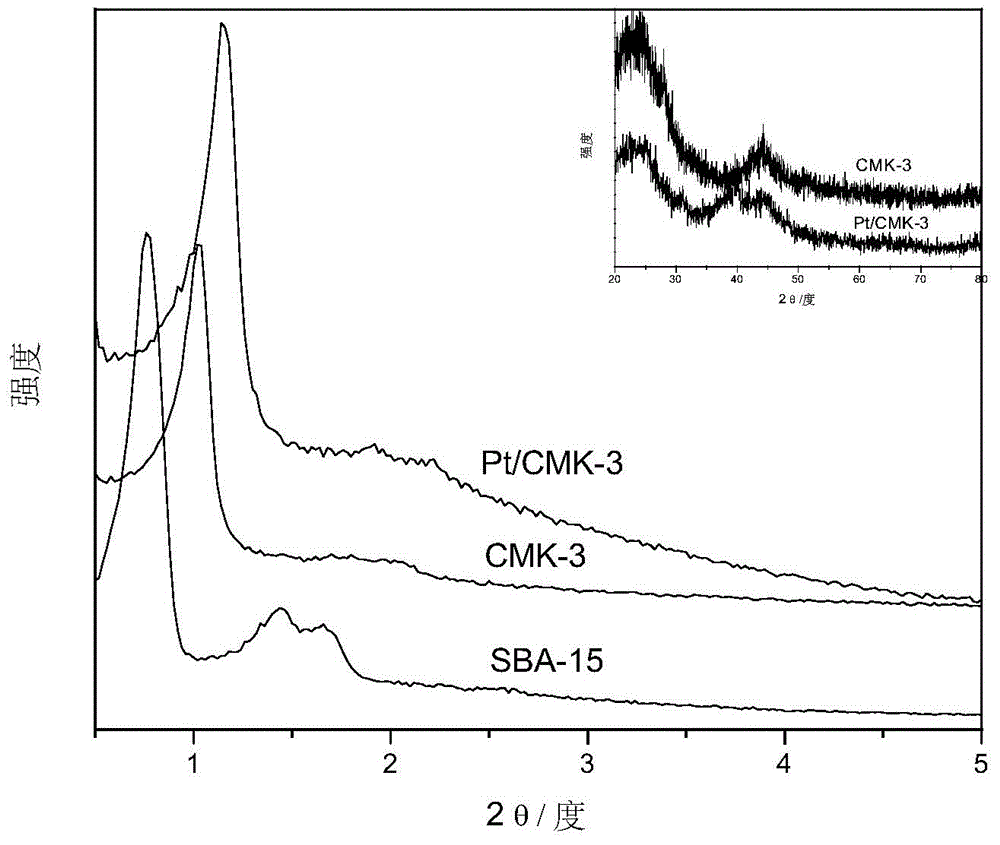

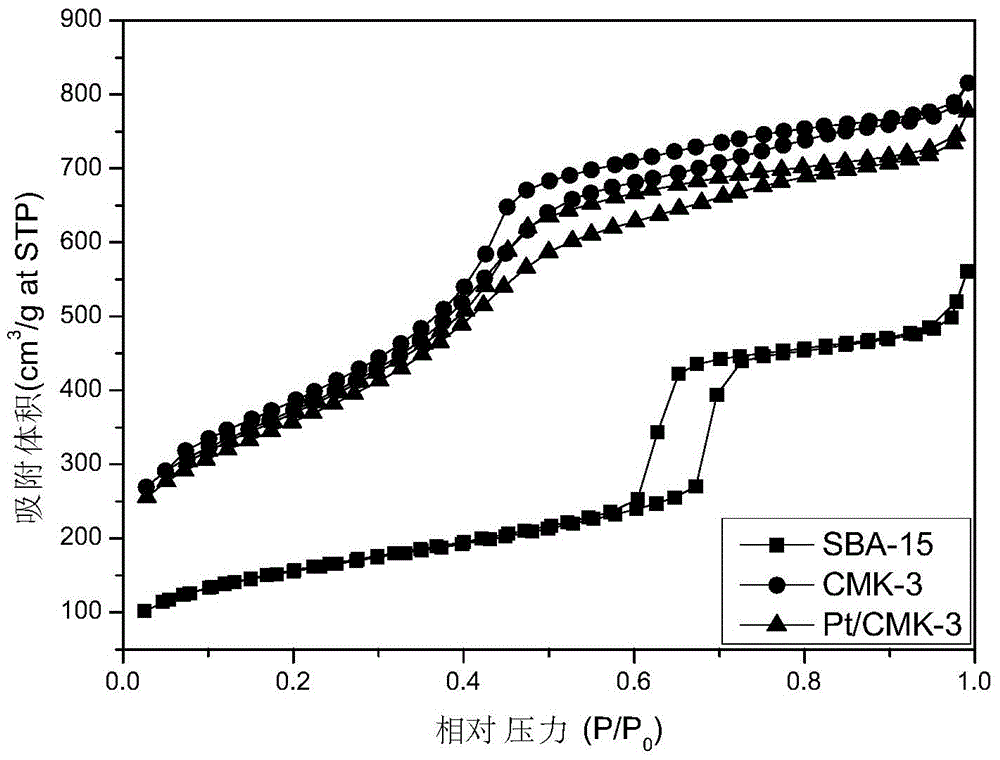

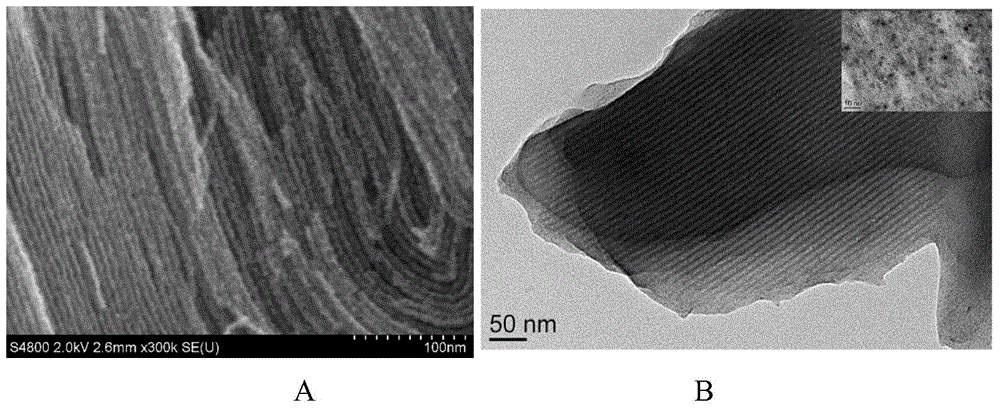

[0045] The prepared catalyst number is Pt / CMK-3, and the small angle and large angle X-ray diffraction...

Embodiment 3

[0050] The mesoporous carbon material supported platinum catalyst Pt / CMK-3 obtained in the above example 2 is used for aromatic nitro compounds (such as nitrobenzene, 2-Cl nitrobenzene, 3-Cl nitrobenzene, 4-Cl nitro Benzene, 2-CH 3 Nitrobenzene, 3-CH 3 Nitrobenzene, 4-CH 3 Heterogeneous catalytic hydrogenation of nitrobenzene, 2-MeO nitrobenzene and 4-MeO nitrobenzene). Below with Pt / CMK-3 mesoporous carbon material supporting platinum catalyst in the specific embodiment of nitrobenzene catalytic hydrogenation reaction, the application of the present invention is described in further detail, and its specific steps are as follows:

[0051] a, take 50mg Pt / CMK-3 catalyst and pretreat it in a hydrogen atmosphere at a temperature of 673K for 2 hours;

[0052] b. Put the above-mentioned pretreated catalyst, a mixed solution of 18mL water and 2mL ethanol, and 21mmol nitrobenzene into the reaction kettle with pure hydrogen at a pressure of 4.0 MPa, and carry out catalytic hydrog...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com