Catalytic coal gasification catalyst and preparation method and application thereof

A coal catalytic gasification and catalyst technology, which is applied in the direction of physical/chemical process catalysts, chemical instruments and methods, fixed bed gasification, etc., can solve problems such as expensive catalysts, difficult catalyst recovery, and reactor material corrosion, and achieve faster The pace of industrial application, satisfying clean and efficient utilization, and the effect of strong interaction force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Weigh 5.9 g of KCl, add 40 mL of deionized water, after completely dissolving, add 1.5 g of Zhundong coal into it, continue to stir to mix evenly, centrifuge, wash, dry, crush and sieve to 60 Mesh-100 mesh, the catalyst is marked as KCl-ZD.

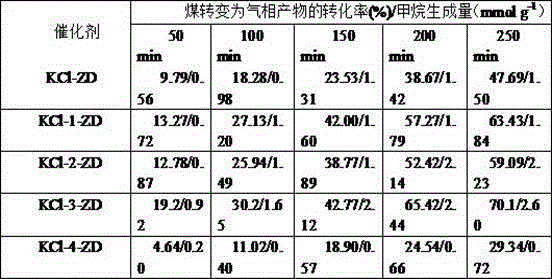

[0021] Coal catalytic gasification reaction conditions: deionized water flow rate 1.0 mL / min, reaction temperature 973 K, reaction system pressure 3.4 MPa. The change curve of carbon conversion rate on the catalyst with time and CH 4 The accumulated precipitation amount is shown in Table 1.

Embodiment 2

[0023] Weigh 5.9 g of KCl and dissolve it in 40 mL of deionized water. After it is completely dissolved, add 1.5 g of Zhundong coal into it, continue stirring to mix evenly, measure 40 mL of ammonia water, and add it dropwise to the suspension , continue to stir until the pH value of the solution remains unchanged, centrifuge, wash, dry, crush and sieve to 60-100 mesh after tableting, and the catalyst is marked as KCl-1-ZD.

[0024] Coal catalytic gasification reaction conditions: deionized water flow rate 1.0 mL / min, reaction temperature 973 K, reaction system pressure 3.4 MPa. The change curve of carbon conversion rate on the catalyst with time and CH 4 The accumulated precipitation amount is shown in Table 1.

Embodiment 3

[0026] Weigh 5.9 g of KCl and dissolve it in 40 mL of deionized water. After it is completely dissolved, add 1.5 g of Zhundong coal into it, continue stirring to mix evenly, measure 60 mL of ammonia water, and add it dropwise to the suspension , continue to stir until the pH value of the solution remains unchanged, centrifuge, wash, dry, crush and sieve to 60-100 mesh after tableting, and the catalyst is marked as KCl-2-ZD.

[0027] Coal catalytic gasification reaction conditions: deionized water flow rate 1.0 mL / min, reaction temperature 973 K, reaction system pressure 3.4 MPa. The change curve of carbon conversion rate on the catalyst with time and CH 4 The accumulated precipitation amount is shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com