Wet technology for recycling asbestos and mineral fibers in asbestos mineral tailings

A technology of mineral fiber and wet process, applied in the field of mineral processing technology, can solve the problems of asbestos tailings recovery, difficult separation, increased screening, etc., to improve asbestos recovery rate and return water utilization rate, high recovery rate of mineral processing, The effect of improving economic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

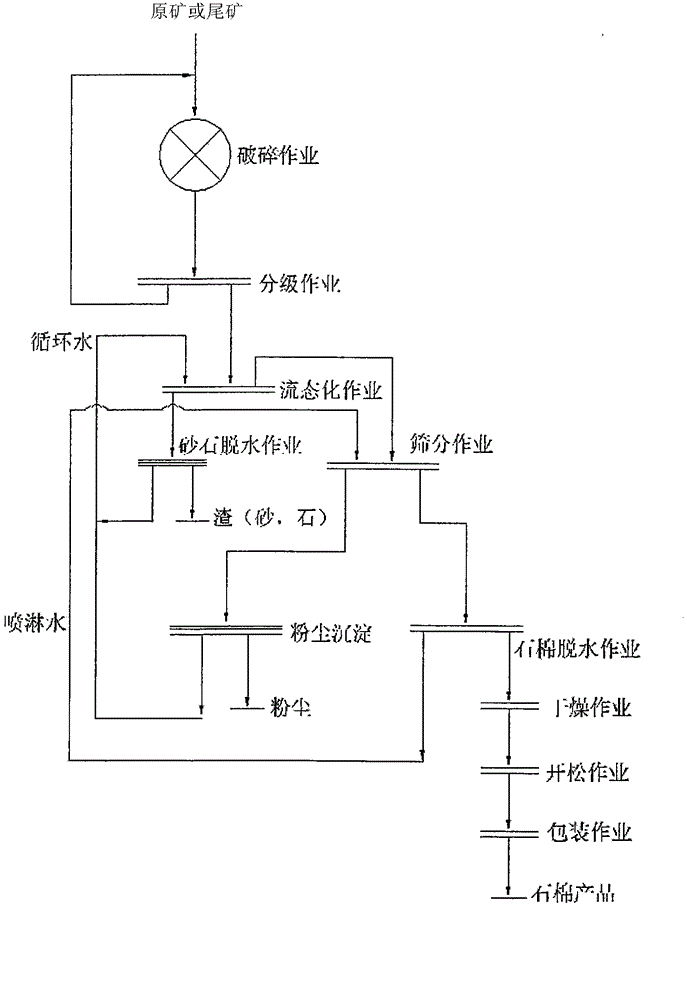

[0049] Asbestos Tailings Rough Selection Material Wet Washing Technology

[0050] (1) Crushing and roughing The material used in this embodiment is the rough concentrate after the asbestos tailings are pre-processed through crushing and dry air separation in the mine. The content of asbestos in the tailings is about 3%. After the pre-selection, the rough concentrate The asbestos content of the raw material is 30-40%, and the rest is sand, stone, dust, and the maximum particle size of the material is ≤30mm. Coarse concentrate is transported to the ore bin and mixed, and fed into the fluidization process by the belt.

[0051] (2) The advantage of fluidized separation and sand removal as the first process is that it can reduce the wear of sand on the screen and the sedimentation in the pipeline. Sand removal adopts TT-200 fluidized bed, The hourly processing capacity is 40 tons. Three compartments, the fluidized bed screen area is 200×450cm. When the compressed air pressure i...

Embodiment 2

[0062] Wet washing process of serpentine asbestos raw ore

[0063] Embodiment 2 has the same process and equipment flow as Embodiment 1, and the difference is that the raw ore mined in the mine is transported to the washing plant for washing after the mine is crushed.

[0064] (1) Raw ore crushing Raw ore goes through a section of jaw crushing and a section of vertical shaft crushing before being selected. The ore particle size is ≤300mm. The raw ore has a cotton content of 5.8% and a moisture content of less than 3%.

[0065] (2) After the fluidized sorting raw ore enters the raw ore bin, the ore is released by the vibrating feeder and transported by the belt conveyor, and the ore is evenly sent into the fluidized bed at a feeding rate of 35 tons per hour. Because the grade of asbestos in the raw ore is lower than that of the tailings coarse concentrate, the dust content is less, the stones and sand particles are large, the asbestos fibers are long, and there are few inclusio...

Embodiment 3

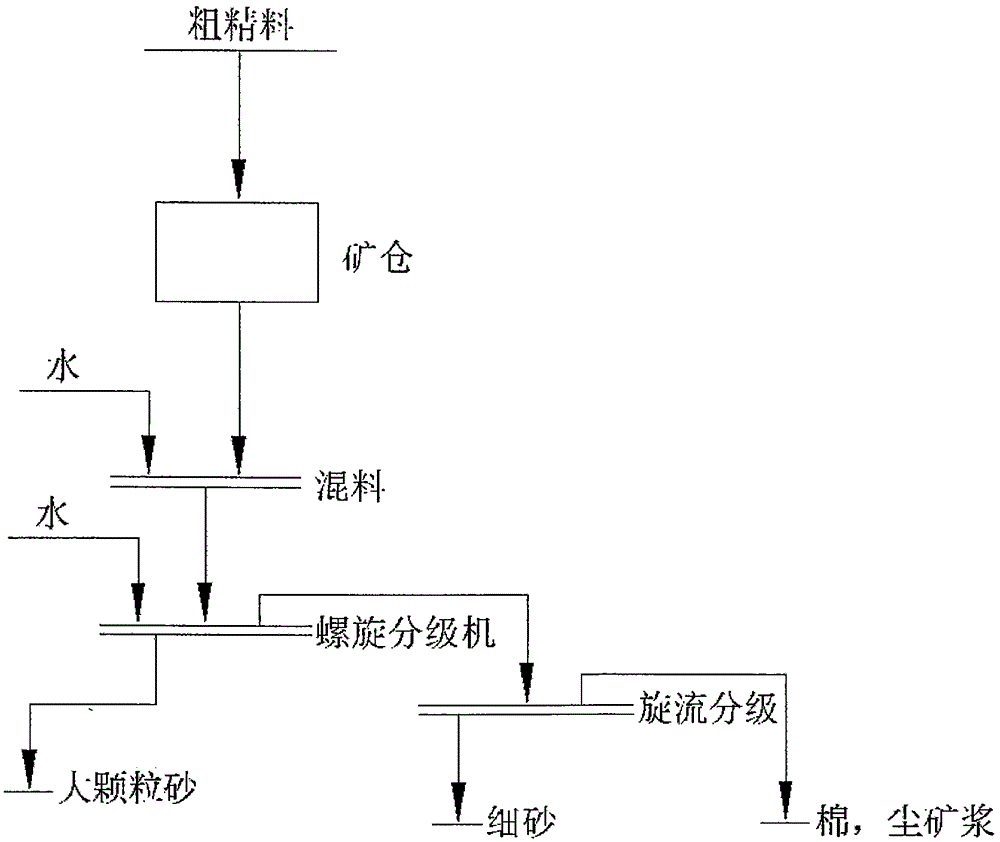

[0072] Gravity separation process of asbestos tailings coarse concentrate

PUM

| Property | Measurement | Unit |

|---|---|---|

| Inclination | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com