Metal-fiber foamed aluminum composite layer plate and preparation method thereof

A metal fiber and foamed aluminum technology, which is applied in the field of metal fiber foamed aluminum composite laminates and the preparation thereof, can solve the problem that the shock absorption performance and high temperature resistance performance are not improved, the preparation cost of fiber metal laminates is high, and the foam metal sandwich panel is fireproof. The performance has not been improved, and the effect of good bending deformation resistance, superior mechanical properties, and high energy absorption performance has been achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

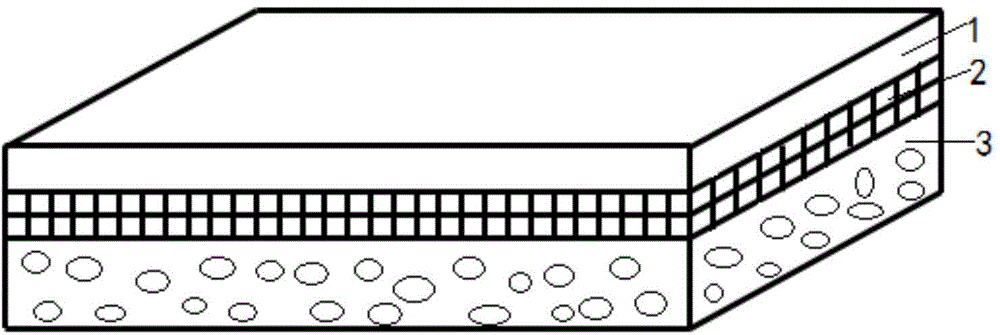

[0041] A metal fiber foam aluminum composite laminate, the structure of which is at least one metal plate layer 1, at least one fiber layer 2 and at least one foam aluminum layer 3;

[0042] The fiber layer 2 is alternately bonded to the aluminum foam layer 3 through a high temperature resistant polymer adhesive compound, and the upper and lower sides of the aluminum foam layer 3 are bonded to the fiber layer 2;

[0043] The metal sheet layer 1 is bonded to the fiber layer 2 as the outermost layer by a high-hardness polymer adhesive compound.

[0044] see figure 1As shown, it is a structural schematic diagram of the metal fiber foam aluminum composite laminate in the present invention. In the figure, the metal laminate 1, the fiber layer 2 and the foamed aluminum layer 3 are all one layer, and as mentioned above, there is a high-hardness polymer adhesive compound between the metal plate layer 1 and the fiber layer 2, and the fiber layer 2 Between the aluminum foam layer 3 is...

Embodiment 2

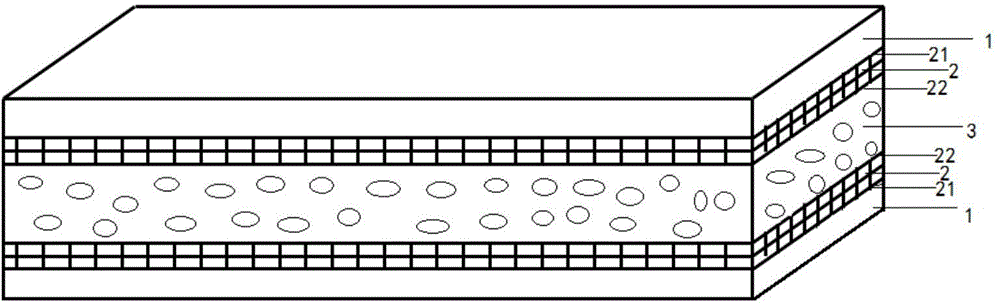

[0046] see Figure 2a , which is a structural schematic diagram of the metal fiber aluminum foam composite laminate of the present invention, Figure 2b It is a structural diagram of the metal fiber aluminum foam composite laminate of the present invention. It can be seen from the figure that the structure is the ordinary carbon steel plate layer 1, the fiber layer 2, the foamed aluminum layer 3, the fiber layer 2 and the ordinary carbon steel plate layer 1 from top to bottom. , between the fiber layer 2 and the ordinary carbon steel plate layer 1 is a high-hardness polymer adhesive compound 21, the high-hardness polymer adhesive compound 21 is an epoxy resin adhesive, an amine curing agent and nitrogen When the mixture of titanium nitride microparticle materials, and the mass ratio of epoxy resin adhesive, amine curing agent and titanium nitride microparticles meet the following relationship (calculated according to 100g per part of epoxy resin), the high hardness polymer Ad...

Embodiment 3

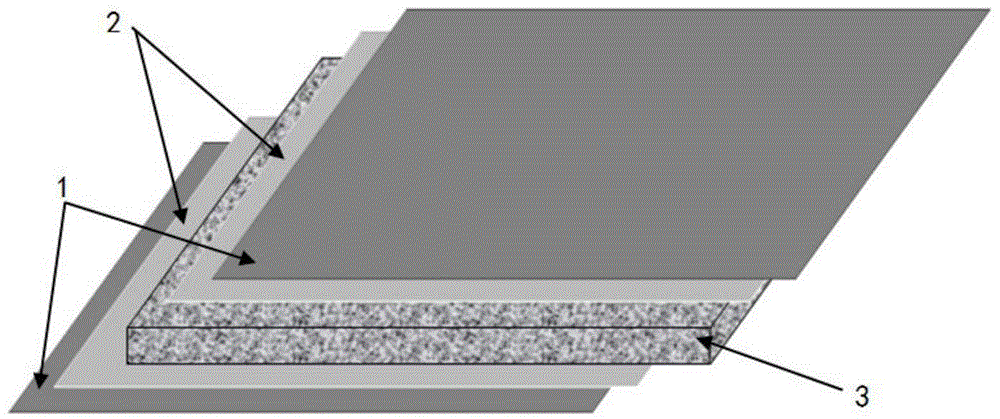

[0078] see image 3 As shown, it is a structural schematic diagram of the metal fiber aluminum foam composite laminate of the present invention. Three layers of fiber layers 2 and two layers of foamed aluminum layers 3 are alternately bonded to form a sandwich layer, and two layers of stainless steel plate layers 1 are used as the outermost layer to bond with the fiber layer 2, and the fiber layer 2 is compounded by a high-hardness polymer adhesive The object 21 is bonded to the stainless steel plate 1. The high-hardness polymer adhesive compound 21 in this embodiment is a mixture of epoxy resin adhesive, acid anhydride curing agent and titanium nitride micron particle material, and the ring When the mass ratio of epoxy resin adhesive, acid anhydride curing agent and titanium nitride micron particles meets the following relationship (calculated by every 100g of epoxy resin), the adhesiveness of this high-hardness polymer adhesive compound 21 And titanium nitride micro-particl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com