Method for preparing zinc oxide by using ultrasonic synthesis method

A technology of ultrasonic synthesis and zinc oxide, which is applied in the direction of zinc oxide/zinc hydroxide, etc., can solve the problems such as the difficulty of zinc oxide morphology, and achieve the effect of simple synthesis method, increased adsorption capacity, and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

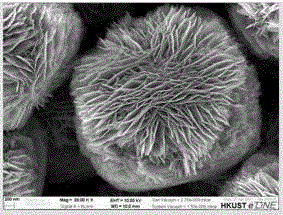

[0036]Prepare 50 mL each of 0.1 mol / L zinc chloride solution and 0.5 mol / L sodium hydroxide solution, then transfer the alkaline solution to a 250 mL beaker, react at 22 °C and put it into a stirring paddle for mechanical stirring, while Perform ultrasonic dispersion. Next, under the action of ultrasound, slowly add zinc chloride solution to the above sodium hydroxide solution at a rate of about 25ml / L, and then continue ultrasonic dispersion for 60s. After standing for 3 hours, filter off the supernatant liquid, then add deionized water to continue washing until the pH value of the supernatant is neutral, finally wash with absolute ethanol, and dry at 70°C to obtain a white solid Powder, denoted as sample T 1 , and its SEM photo is as figure 1 shown.

Embodiment 2

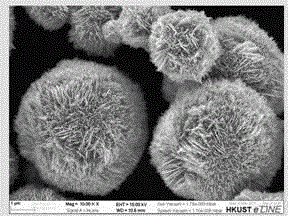

[0038] Prepare 50 mL each of 0.1 mol / L zinc chloride solution and 0.5 mol / L sodium hydroxide solution, then transfer the alkaline solution to a 250 mL beaker, react at 22 °C and put it into a stirring paddle for mechanical stirring, while Perform ultrasonic dispersion. Next, under the action of ultrasound, slowly add zinc chloride solution to the above sodium hydroxide solution at a rate of about 25ml / L, and then continue ultrasonic dispersion for 60s. After standing for 3 hours, filter off the supernatant liquid, then add deionized water to continue washing until the pH value of the supernatant is neutral, and finally wash with absolute ethanol, and dry at 80°C to obtain a white solid Powder, denoted as sample T 2 , and its SEM photo is as figure 2 shown.

Embodiment 3

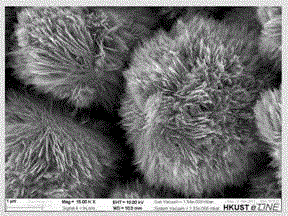

[0040] Prepare 50 mL each of 0.05 mol / L zinc nitrate solution and 0.25 mol / L potassium hydroxide solution, then transfer the potassium hydroxide solution to a 250 mL beaker, react at 22 °C and put it into a stirring paddle for mechanical stirring, while Perform ultrasonic dispersion. Next, under the action of ultrasound, slowly add zinc nitrate solution to the above potassium hydroxide solution, the addition rate is about 25ml / L, and then continue ultrasonic dispersion for 60s. After standing for 3 hours, filter off the supernatant liquid, then add deionized water to continue washing until the pH value of the supernatant is neutral, and finally wash with absolute ethanol, and dry at 80°C to obtain a white solid Powder, denoted as sample C 1 , and its SEM photo is as image 3 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com