Method for treating high-concentration ammonia nitrogen pig breeding biogas slurry

A high-concentration biogas slurry technology, which is applied in the field of pig-raising biogas slurry treatment, can solve the problems of high raw material costs, reduce production costs, reduce environmental treatment costs, and realize the effects of resource utilization of waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0020] Embodiment: implement by following technological process.

[0021] (1) Activation of artificial zeolite: immerse the artificial zeolite in a sodium chloride solution with a concentration of 0.5 mol / L, heat it in a water bath at 100 °C for 2 h, take it out, and dry it to obtain an activated artificial zeolite.

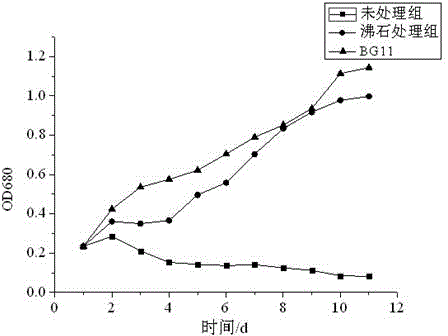

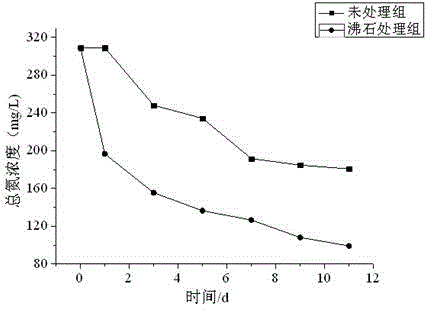

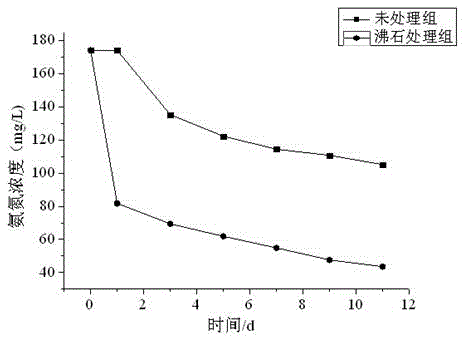

[0022] (2) Pretreatment of biogas slurry: heat-treat pig biogas slurry at 100°C for 20 minutes, and centrifuge at 4800 rpm after cooling. The supernatant is high-concentration ammonia nitrogen pig biogas slurry, with total nitrogen of 308.97 mg / L and ammonia nitrogen of 174.07 mg / L, the total phosphorus is 35.89 mg / L, and the COD is 361.33 mg / L. Take 3 L of this biogas slurry and put it into a 5 L Erlenmeyer flask as the untreated group.

[0023] (3) Zeolite adsorption treatment of high-concentration ammonia-nitrogen pig biogas slurry: take the activated artificial zeolite in step (1) and put it into the high-concentration ammonia nitrogen pig biogas slurry in s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com