Soil remediation agent for reducing high-concentration cobalt and lead pollution and application of soil remediation agent

A soil remediation agent and lead pollution technology, applied in the field of soil remediation, can solve the problems of reducing the concentration of cobalt and lead, poor effect, side effects, etc., and achieve the effect of high remediation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

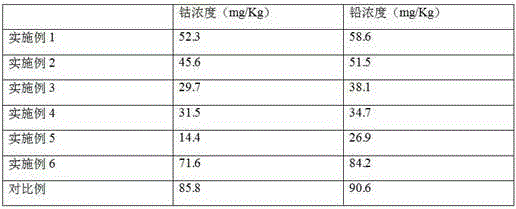

Examples

Embodiment 1

[0046] (1) Calcite powder, calcium chloride, sodium pyrophosphate, and carboxymethyl cellulose are all pulverized respectively until the above-mentioned raw materials are 200 mesh; (2) Cetylbenzene sulfonate sodium is 5Kg, 11Kg of calcite powder, 15Kg of tartaric acid, 3Kg of acetylacetone, 6Kg of calcium chloride, 9Kg of sodium pyrophosphate, 12Kg of carboxymethyl cellulose, and 8Kg of triethanolamine. Mix the above materials evenly to make soil remediation agent; (3) Dilute the well-mixed soil remediation agent with deionized water, the weight of deionized water is 15 times the weight of the soil remediation agent, and then evenly spray the mixed solution of soil remediation agent into the soil with high concentration of cobalt and lead pollution, mix The spraying amount of the solution is 0.6Kg / m 2 , plow the soil after spraying.

Embodiment 2

[0048] (1) Calcite powder, calcium chloride, sodium pyrophosphate, and carboxymethyl cellulose are all pulverized respectively until the above-mentioned raw materials are all 300 meshes; (2) Sodium cetylbenzenesulfonate is obtained by weight 13Kg, 4Kg of calcite powder, 7Kg of tartaric acid, 10Kg of acetylacetone, 11Kg of calcium chloride, 4Kg of sodium pyrophosphate, 6Kg of carboxymethyl cellulose, and 4Kg of triethanolamine. Mix the above materials evenly to make soil remediation agent; (3) Dilute the uniformly mixed soil remediation agent with deionized water, the weight of deionized water is 5 times the weight of the soil remediation agent, and then evenly spray the mixed solution of soil remediation agent into the soil with high concentration of cobalt and lead pollution, mix The spraying amount of the solution is 2.0Kg / m 2 , plow the soil after spraying.

Embodiment 3

[0050] (1) Calcite powder, calcium chloride, sodium pyrophosphate, and carboxymethyl cellulose are all pulverized respectively until the above-mentioned raw materials are 200 mesh; (2) Cetylbenzene sulfonate sodium is 7Kg, 9Kg of calcite powder, 13Kg of tartaric acid, 4Kg of acetylacetone, 10Kg of calcium chloride, 5Kg of sodium pyrophosphate, 11Kg of carboxymethyl cellulose, and 7Kg of triethanolamine. Mix the above materials evenly to make soil remediation agent; (3) Dilute the well-mixed soil remediation agent with deionized water, the weight of deionized water is 15 times the weight of the soil remediation agent, and then evenly spray the mixed solution of soil remediation agent into the soil with high concentration of cobalt and lead pollution, mix The spraying amount of the solution is 0.6Kg / m 2 , plow the soil after spraying.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com