Beer yeast cell disruption method adopting synergetic enzyme and mechanical disruption

A technology of brewer's yeast cells and mechanical wall breaking, applied in the biological field, can solve the problems of high equipment occupancy rate, poor enzyme targeting, long enzymatic hydrolysis time, etc., and achieve low equipment occupancy rate, low production cost, and short wall breaking time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1 (comparison)

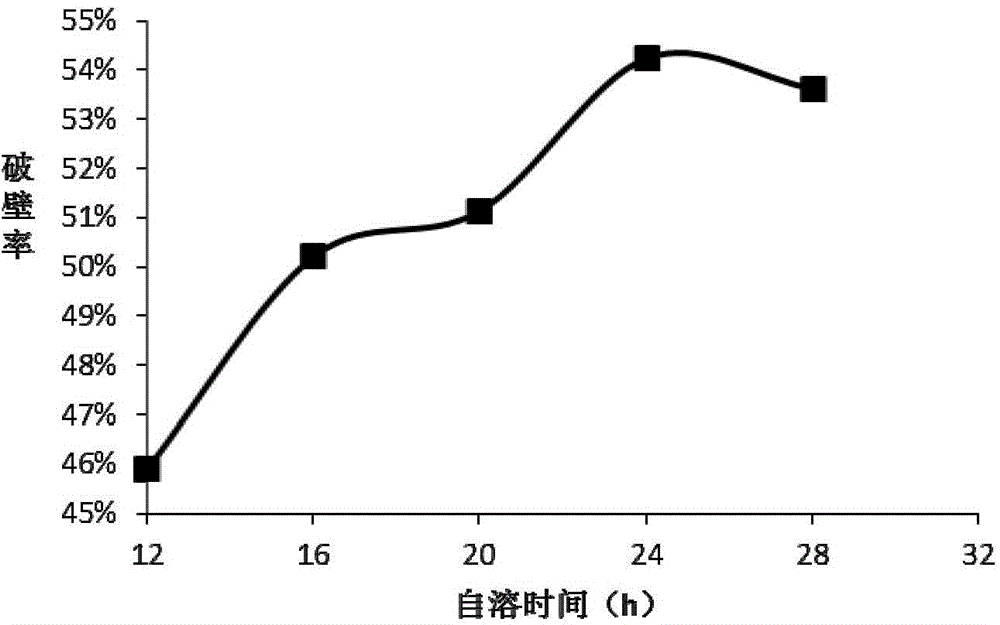

[0031] Suspend beer yeast slime in water to obtain a beer yeast suspension with a mass concentration of 15%, and perform autolysis and hydrolysis at pH=5, 50°C. For the influence of autolysis time and wall breaking rate, see figure 1 . Such as figure 1 As shown, under this condition, the wall breaking rate reached the highest when autolyzed for 24 hours, which was 55%.

Embodiment 2

[0032] Embodiment 2 (comparison)

[0033] Beer yeast slurry is mixed with water to make a mass concentration of 50% beer yeast suspension;

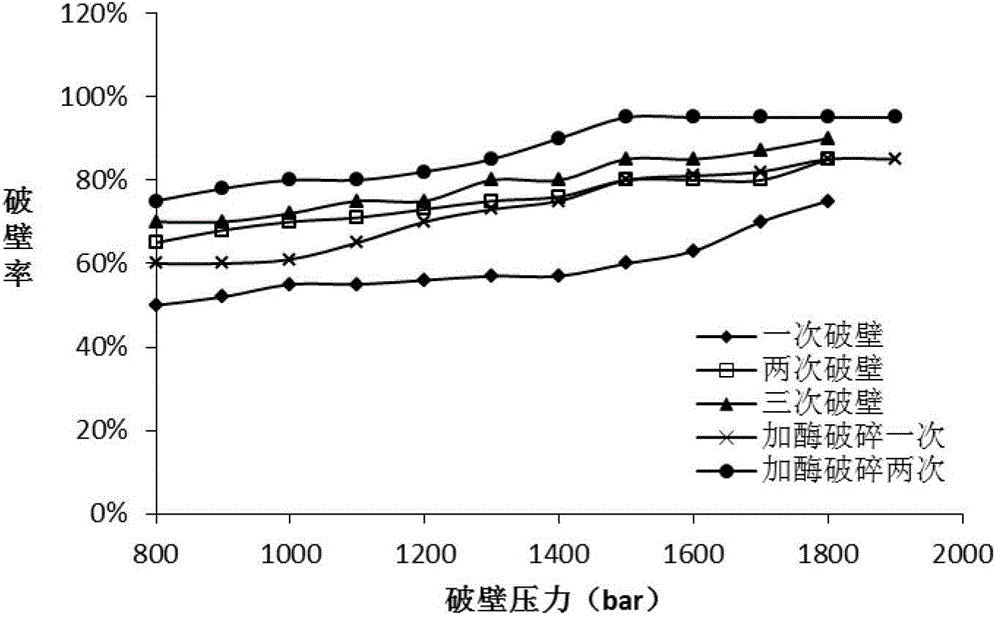

[0034] A high-pressure homogeneous crusher is used to break the wall, and the outlet temperature is 20°C. The impact of the breaking pressure and the number of breaking times (one breaking, two breaking, three breaking) on the breaking rate is shown in figure 2 .

[0035] With the increase of the breaking pressure, the breaking rate increases. Under the pressure of 1800-1900bar, the first breaking rate is about 75%, and the second breaking rate reaches 85%. If the breaking rate is required to reach more than 90%, Three breaks are required.

Embodiment 3

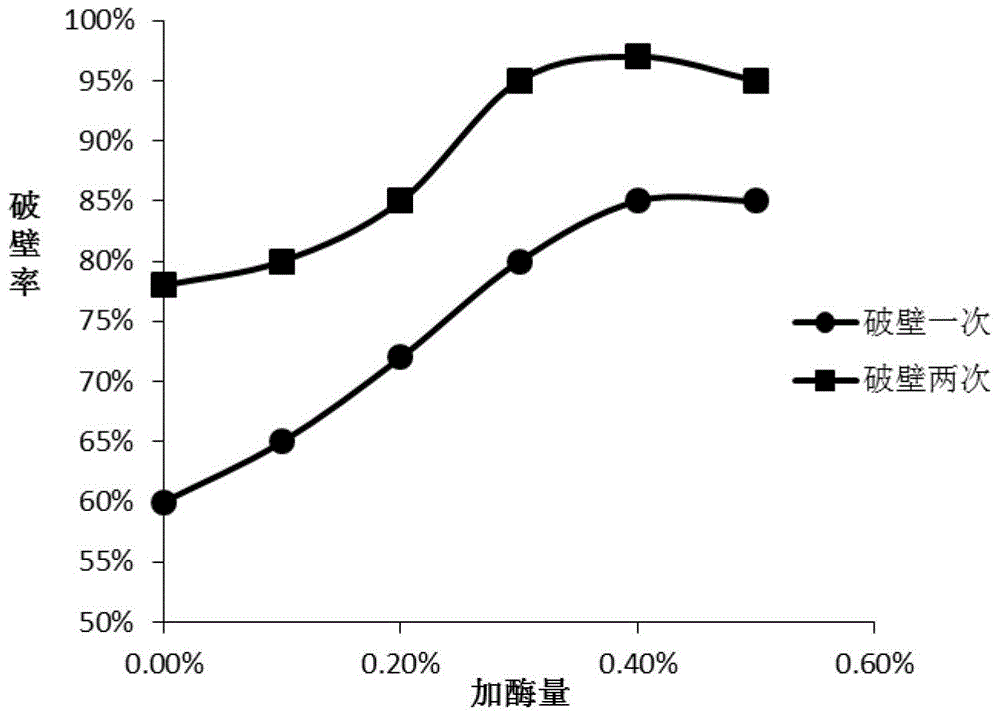

[0037] The composite enzyme I consists of the following raw materials in parts by weight: 5 parts of protease, 2 parts of cellulase, 0.5 part of chitinase and 0.3 part of mannanase.

[0038] The enzyme activity of protease is 100000U / ml, the enzyme activity of cellulase is 200U / ml, the enzyme activity of chitinase is 30U / ml, and the enzyme activity of mannanase is 35000U / ml.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com