A kind of Lactobacillus plantarum with high yield of ethyl caprate and application thereof

A technology of Lactobacillus plantarum and curd, applied in the field of microbiology, can solve problems such as unconsidered influence, and achieve the effects of low cost, improved product sensory quality characteristics, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

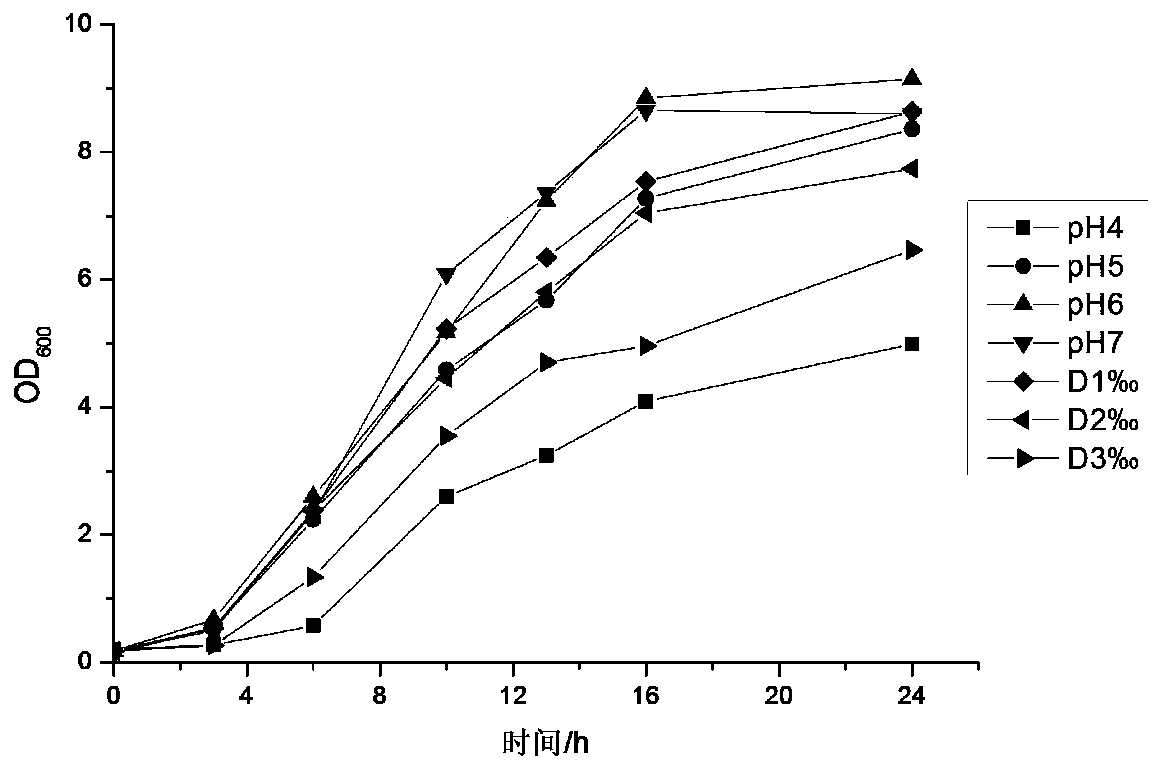

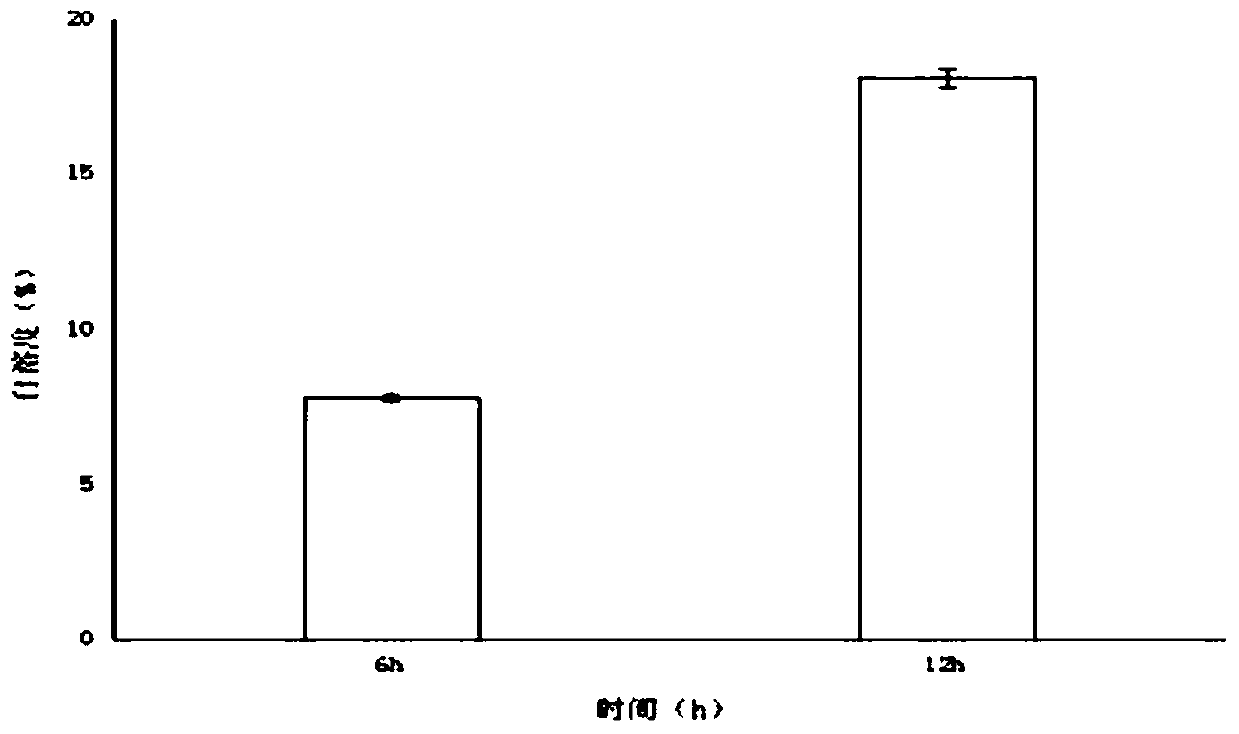

Method used

Image

Examples

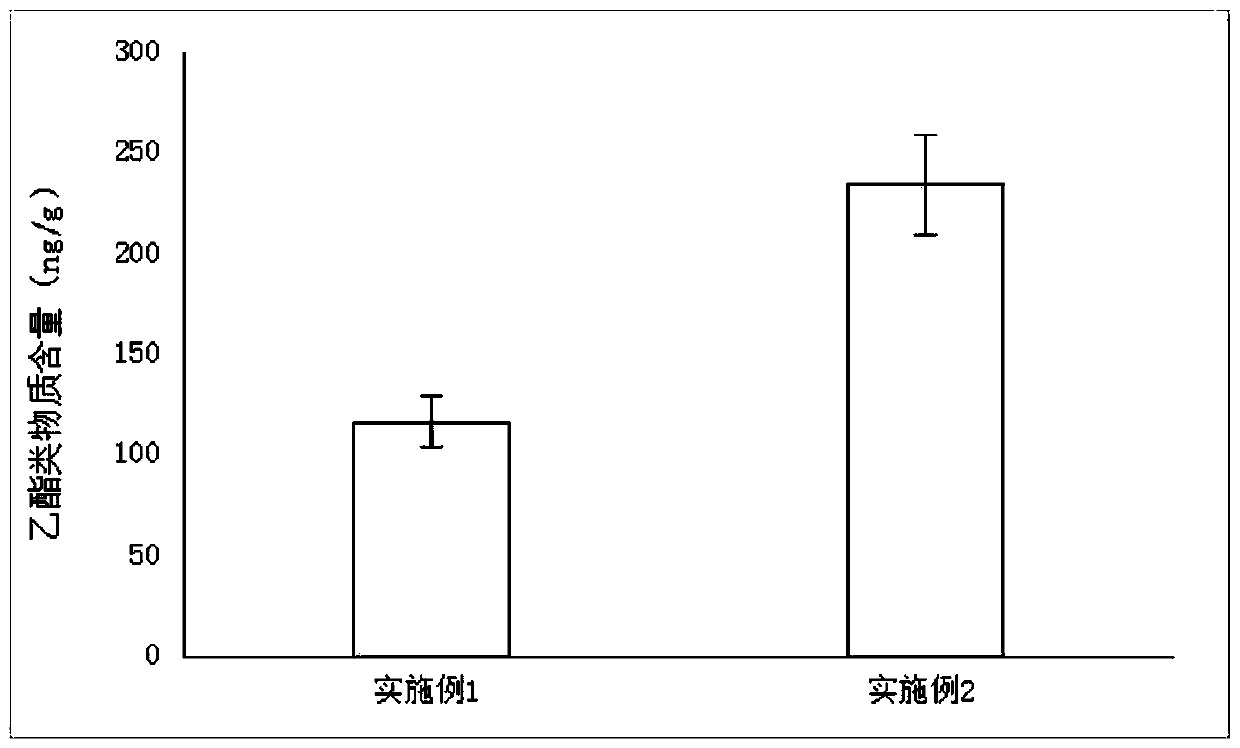

Embodiment 1

[0023] Example 1 Camembert cheese without Lactobacillus plantarum CGMCC No. 9739

[0024] The production process of Camembert cheese is as follows: the raw milk is pasteurized and quickly cooled to 32°C, and starter (Lactococcus lactis-MA 14 LYO, Danisco) and mold starter (penicillium cartieri-PC 12 LYO 20) are added. D,Danisco and Geotrichum candidum-GEO17 LYO 2 D,Danisco), keep at 32℃ for 30-40min, add 800μg / g ethanol to the milk, add a certain amount of rennet for 45min, and cut the clot After forming into cube particles with a side length of 1 cm, they are heated and cured at 32°C and then slowly stirred to remove the whey, and the cheese with the curd in the mold is pressed and shaped to further remove the whey. After the whey is removed, the cheese is left in the air for a period of time for salting. Then place it at a certain temperature for maturation.

[0025] Specific steps are as follows:

[0026] A) Pretreatment of raw milk: qualified standardized raw milk purchased fr...

Embodiment 2

[0032] Example 2 Camembert cheese with Lactobacillus plantarum CGMCC No. 9739

[0033] 1. Preparation of Lactobacillus plantarum CGMCC No. 9739 direct injection working starter.

[0034] Lactobacillus plantarum CGMCC No. 9739 is inoculated into MRS liquid medium at an inoculum of 1-3%, and cultured at 37°C for 20-24 hours, so that the number of viable Lactobacillus plantarum CGMCC No. 9739 reaches 10 8 Cfu / mL or more, centrifugal treatment, centrifugation conditions: 4000rpm, 10min, 4℃, after washing the precipitate twice with pH 7.0 PBS buffer, add lyophilized protective agent to adjust the cell concentration to 10 9 cfu / mL, the mixture is uniformly mixed and then vacuum freeze-dried, and the Lactobacillus plantarum CGMCC No. 9739 direct-cast working starter is obtained after freeze-drying.

[0035] 2. Production of Camembert cheese containing Lactobacillus plantarum CGMCC No. 9739

[0036] The production process of Camembert cheese is as follows: the raw milk is pasteurized and quick...

Embodiment 3

[0059] Example 3 Preparation of Swiss cheese using Lactobacillus plantarum CGMCC No. 9739

[0060] Cool the pasteurized milk to 35°C (maintain this temperature during the subsequent operation of cheese), add thermophilic starter and propionic acid bacteria starter, pre-acidify for a period of time, add the following Lactobacillus plantarum CGMCCNo.9739 attached starter, stir well. Then add rennet for coagulation. After the curd is completed, the cutting operation is performed. After cutting, let it stand for a period of time with heat preservation, program the temperature to 54°C while stirring for blanching treatment. After blanching time 45min, the milking treatment is performed. Put the whey-excluded curd into a mold for shaping and further whey-exclusion operations. The working temperature is 50° C., the duration is 9 hours, and it is turned over every 3 hours. Carry out the salt treatment for the curd after milk discharge at a temperature of 7°C for 2 days. After the salt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com