Titanium dioxide nanowire array film, and preparation and application thereof

A nanowire array and titanium dioxide technology, applied in chemical instruments and methods, chemical/physical processes, physical/chemical process catalysts, etc., can solve problems such as harsh reaction conditions, and achieve simple operation and green process effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

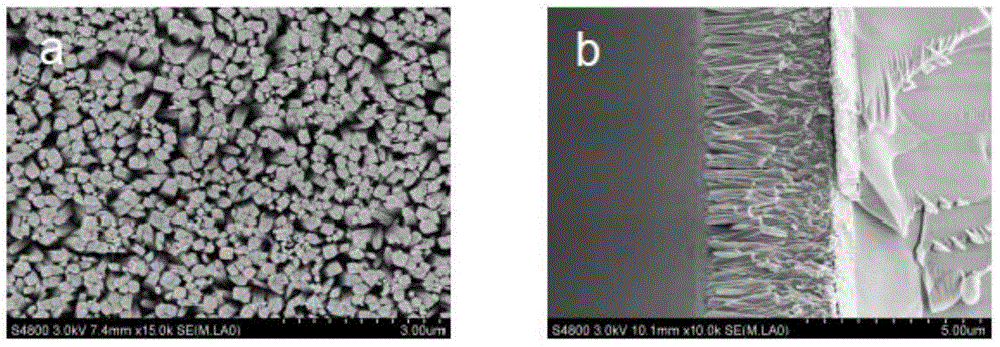

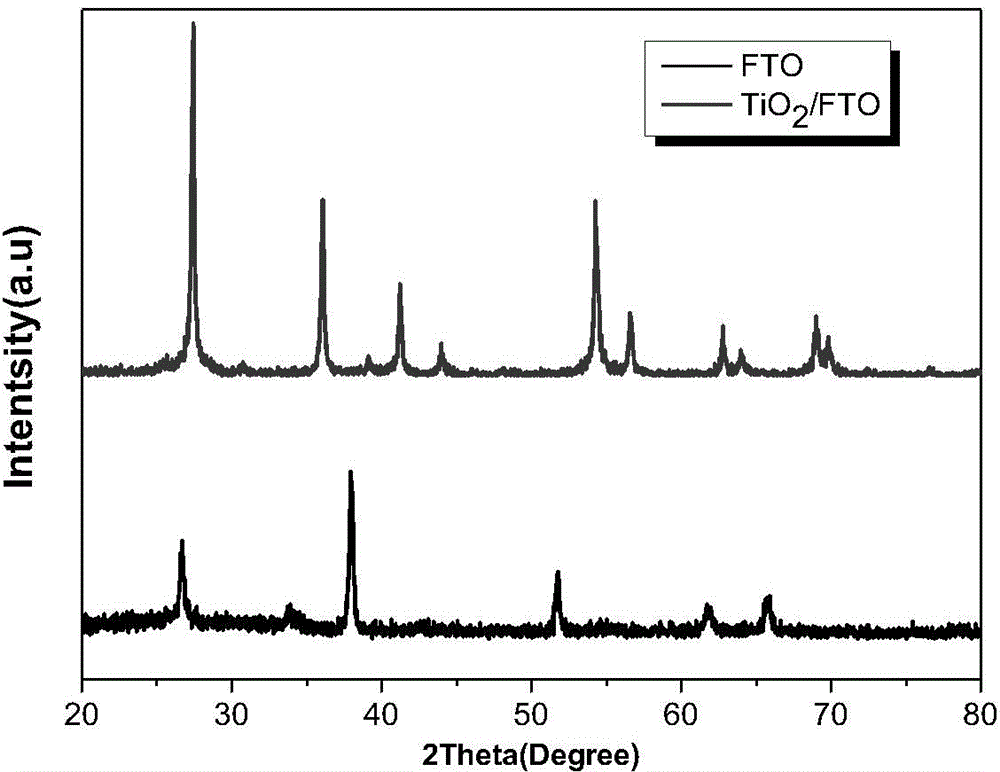

Embodiment 1

[0022] 30mL ultrapure water and 30mL HCl (concentration required) were stirred at 293K for 10min in advance, then added 1.2mL isopropoxide titanyl and continued to stir for 10min, then put it and FTO conductive glass into a 100mL polytetrafluoroethylene kettle and put it under water at 428K Heat for 4 hours. After cooling for 20 minutes under water shower conditions, rinse with ultrapure water, dry at room temperature for 12 hours under dark conditions, and finally calcinate in a muffle furnace at 200 ° C for 2 hours to obtain TiO 2 Nanowire Array Films. In 180mL 0.5M Na 2 SO 4 In a three-electrode system with a piece of TiO 2 The nanowire array film is the working electrode, and the other TiO 2 The thin film is the counter electrode, light is irradiated on the working electrode for 5 minutes, the counter electrode turns black, and the black TiO 2 The thin film is connected to the Pt electrode to realize energy release. Hydrogen is evolved on the Pt electrode. Taking 10 c...

Embodiment 2

[0024] In 120mL 0.5M Na 2 SO 4 , Add 30mL 5ppm methyl orange and 30mL0.5M Na to the working electrode solution 2 SO 4 , in a three-electrode system with a piece of TiO 2 The nanowire array film is the working electrode, and the other TiO 2 The thin film is the counter electrode, and the light is irradiated on the working electrode for 5 minutes, methyl orange is degraded, the counter electrode turns black, and the black TiO 2 The film is connected to the Pt electrode to realize energy release, and hydrogen is evolved on the Pt electrode. Taking 10 charge and discharge cycles as a cycle, the measured hydrogen production is shown in Table 2, and the degradation process of 5ppm methyl orange is shown in Figure 4 , all activity data were replicated more than three times.

Embodiment 3

[0026] In 90mL 0.5M Na 2 SO 4 , 90mL 2M ethylene glycol mixed solution and a piece of TiO in the three-electrode system 2 The nanowire array film is the working electrode, and the other TiO 2 The thin film is the counter electrode, apply -1V bias for 1min, the counter electrode turns black, and the black TiO 2 The thin film is connected to the Pt electrode to realize energy release, hydrogen is formed on the Pt electrode, and the amount of hydrogen produced is measured with 10 charge and discharge cycles. All activity data are repeated more than three times.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com