Preparation method and application of three-dimensional porous heteroatom-doped graphene

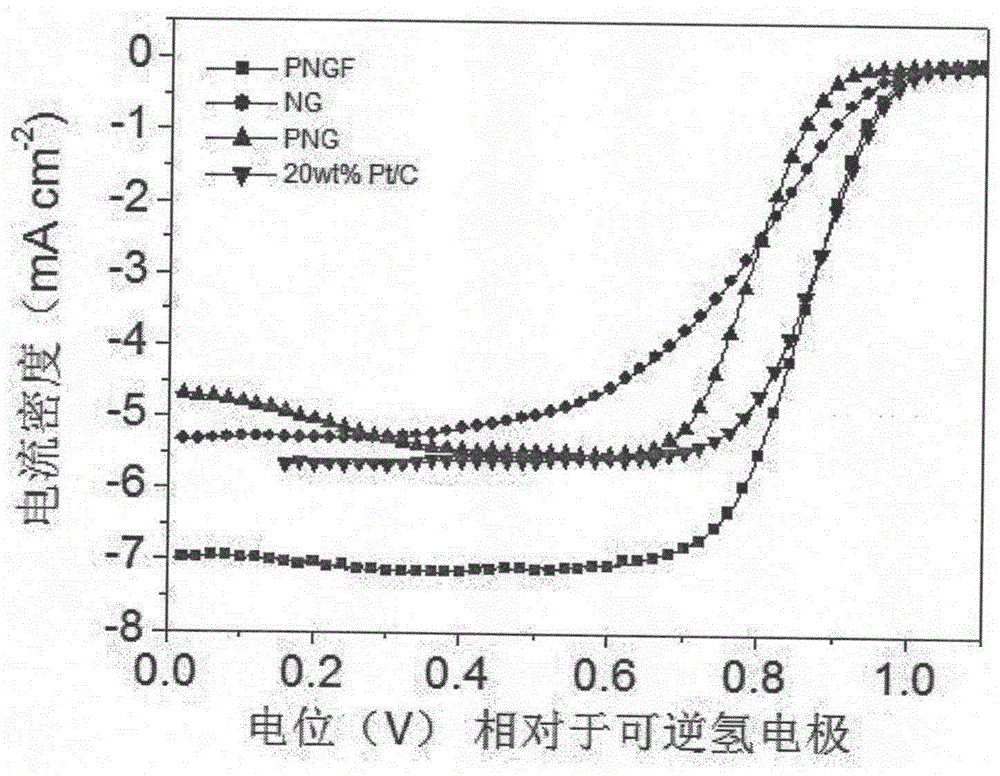

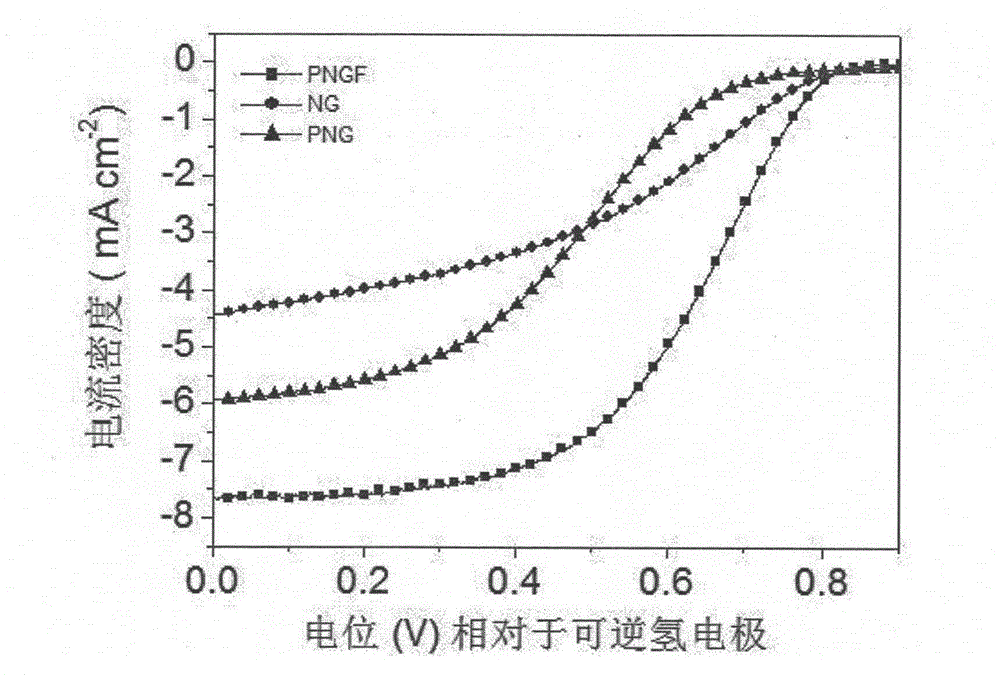

A three-dimensional porous, heteroatom technology, used in chemical instruments and methods, catalyst activation/preparation, physical/chemical process catalysts, etc., can solve problems such as insufficient utilization of specific surface area, achieve good development prospects, reduce agglomeration, The effect of high catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

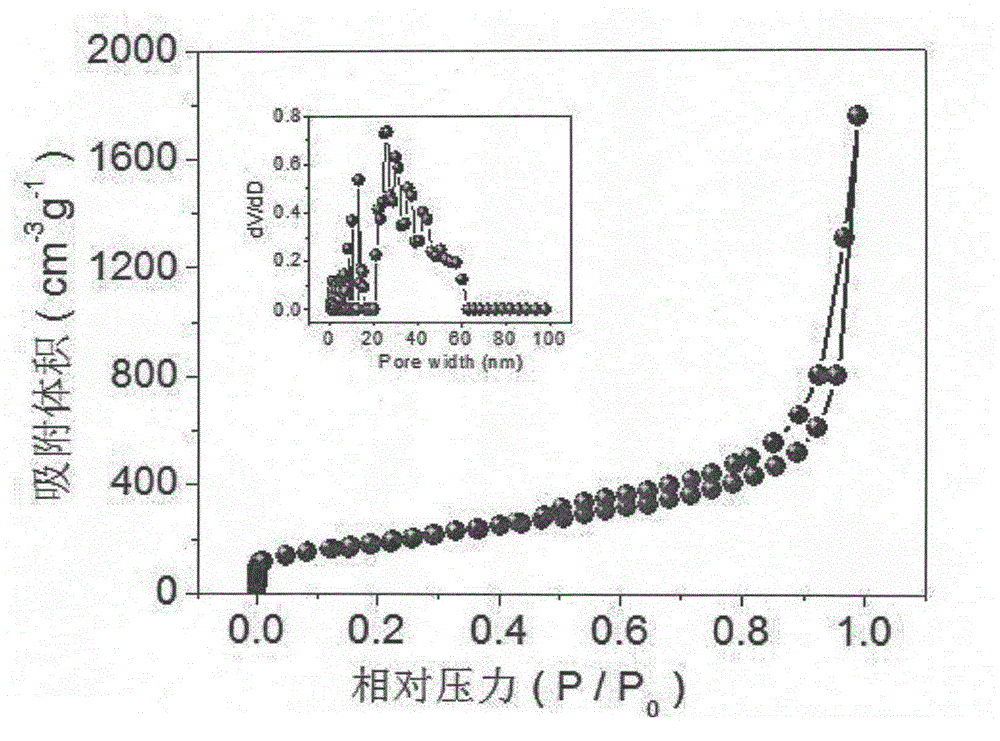

[0027] The invention provides a method for preparing three-dimensional porous heteroatom-doped graphene, the three-dimensional porous heteroatom-doped graphene is prepared by a hard template method, and the steps are as follows:

[0028] In the first step, 200mg graphene oxide, 700mg dicyandiamide, 200mgFeCl 2 4H 2 O and 500mg of silicon dioxide with a diameter of 7nm were uniformly dispersed in ethanol by ultrasonic, heated and stirred at 60°C for 24h, and dried at 85°C to obtain the precursor. The above mass content is based on the total mass of the precursor.

[0029] Wherein, the mass percentage of graphene oxide is 12.5 wt%, the mass percentage of nitrogen atom precursor is 43.75 wt%, the mass percentage of non-noble metal salt is 12.5 wt%, and the mass percentage of template agent is 43.75 wt%.

[0030] In the second step, the above-mentioned precursor is placed in a quartz boat, and the temperature is raised to 900°C under nitrogen protection at a rate of 5°C / min for ...

Embodiment 2

[0042] A preparation method of three-dimensional porous heteroatom-doped graphene is as follows:

[0043] In the first step, 1350mg graphene oxide, 75mg boric acid, 15mgFeSO 4 7H 2 O and 60mg of silicon dioxide with a diameter of 30nm were uniformly dispersed in water by ultrasonic, heated and stirred at 60°C for 24h, and dried at 85°C to obtain the precursor.

[0044]Wherein, the mass percent of graphene oxide is 90wt%, the mass percent of nitrogen atom precursor is 5wt%, the mass percent of non-noble metal salt is 1wt%, and the mass percent of templating agent is 4wt%. The above mass content is based on the total mass of the precursor.

[0045] In the second step, the above-mentioned precursor is placed in a quartz boat, and under the protection of nitrogen, the temperature is raised to 600°C at 10°C / min for calcination and reduction treatment for 1 hour, and a solid product is obtained after cooling.

[0046] The third step is to treat the solid product with a blend of h...

Embodiment 3

[0048] A preparation method of three-dimensional porous heteroatom-doped graphene is as follows:

[0049] The first step, 1050mg graphene oxide, 270mg diphenyl disulfide, 30mgFe(C 2 h 3 o 2 ) 2 and 150 mg of silicon dioxide with a diameter of 300 nm were uniformly dispersed in chloroform by ultrasonic, heated and stirred at 60° C. for 24 hours, and dried at 85° C. to obtain a precursor.

[0050] Wherein, the mass percent of graphene oxide is 70wt%, the mass percent of nitrogen atom precursor is 18wt%, the mass percent of non-noble metal salt is 2wt%, and the mass percent of templating agent is 10wt%. The above mass content is based on the total mass of the precursor.

[0051] In the second step, the above precursor is placed in a quartz boat, and under the protection of argon, the temperature is raised to 800°C at 15°C / min for calcination and reduction treatment for 2h, and a solid product is obtained after cooling.

[0052] The third step is to treat the solid product wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com