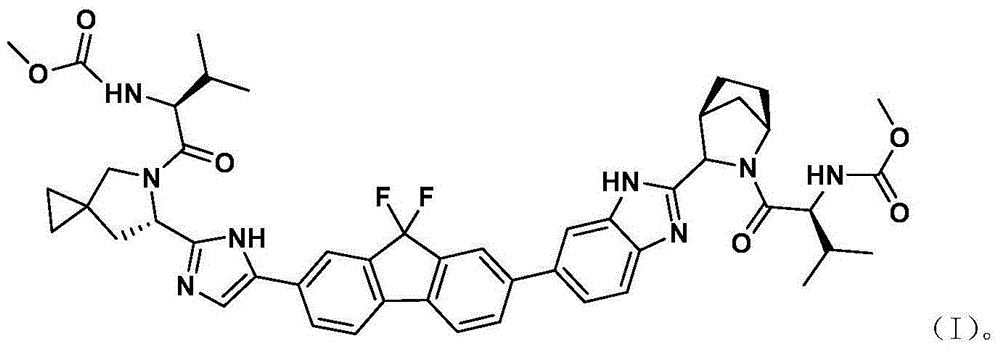

Ledipasvir intermediate preparation method

A unit time, azabicyclic technology, applied in the direction of organic chemistry, can solve the problems of long production cycle, inability to reflect atom economy, cumbersome post-processing, etc., achieve shortened production cycle, high yield, and reduce the use of solvents Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

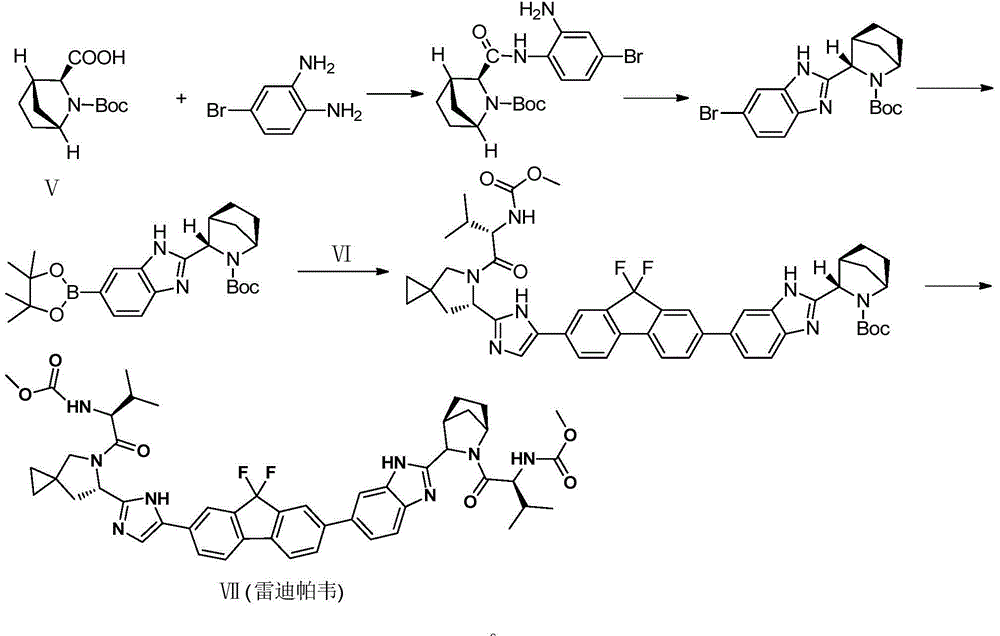

Method used

Image

Examples

Embodiment 1

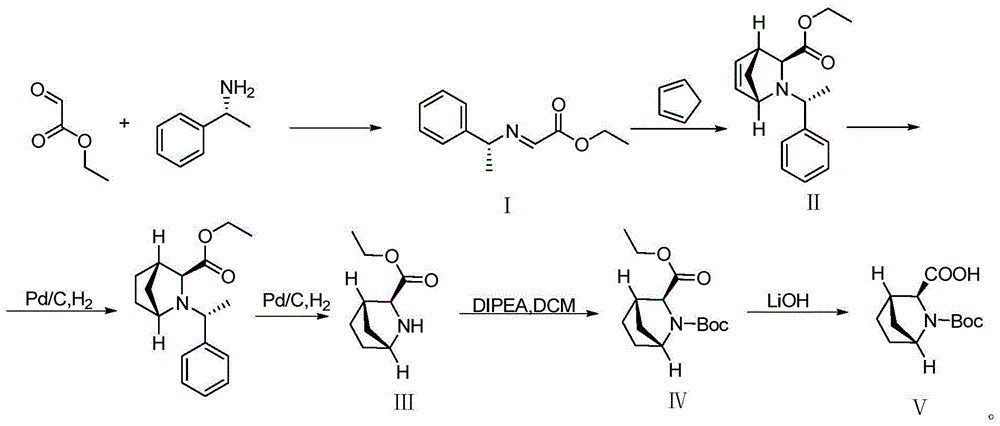

[0034] Example 1 Preparation of (1R, 3S, 4S)-N-tert-butoxycarbonyl-2-azabicyclo[2,2,1]heptane-3-carboxylic acid

[0035] Under the condition of -10°C to 0°C, (R)-phenethylamine (47.5g) was slowly added dropwise to ethyl glyoxylate (80g), Molecular sieves (30g) in toluene (80g), dropwise, react at -10°C to 0°C for 3 hours, add methanol (63.3g), then slowly drop trimethylchlorosilane (85.02g), dropwise, -10 ℃ to 0 ℃ for 2 hours, and then slowly added dropwise the newly prepared cyclopentadiene (50.0g), dropwise, -10 ℃ to 0 ℃ for 3 hours, then added 10% palladium carbon (5.3g), to the reaction Put hydrogen gas into the bottle, react at room temperature about 27°C for 3 hours, then add sodium hydroxide solution (0.8mL, 2mol / L), dropwise, react at room temperature for 2 hours, then lower the reaction system to -5°C to 0°C, Add Boc anhydride (102g), after the addition is complete, react at -10°C to 0°C for 4 hours. After the reaction is complete, remove the filter residue by filtra...

Embodiment 2

[0036] Example 2 Preparation of (1R, 3S, 4S)-N-tert-butoxycarbonyl-2-azabicyclo[2,2,1]heptane-3-carboxylic acid

[0037] -10°C to 0°C, (R)-phenethylamine (47.5g) was slowly added dropwise into dichloromethane (80g) containing methyl glyoxylate (80g), anhydrous sodium sulfate (40g) After dropping, react at -10°C to 0°C for 3 hours, add methanol (63.3g), then slowly add trimethylchlorosilane (85.02g), dropwise, react at -10°C to 0°C for 2 hours, then slowly Add freshly prepared cyclopentadiene (50.0g) dropwise, and react at -10°C to 0°C for 3 hours, then add 5% palladium carbon (10.6g), and pass hydrogen gas into the reaction bottle, and the room temperature is about 27°C React at low temperature for 3 hours, then add sodium hydroxide solution (0.8L, 2mol / L), dropwise, react at room temperature for 2 hours, reduce the reaction system to -5°C to 0°C, add Boc anhydride (102g), and add, React at -10°C to 0°C for 4 hours. After the reaction is complete, remove the filter residue by...

Embodiment 3

[0038] Example 3 Preparation of (1R, 3S, 4S)-N-tert-butoxycarbonyl-2-azabicyclo[2,2,1]heptane-3-carboxylic acid

[0039] Under the condition of -10°C to 0°C, (R)-phenethylamine (47.5g) was slowly added dropwise to ethyl glyoxylate (80g), anhydrous sodium sulfate (40g) in toluene (80g), dropwise After completion, react at -10°C to 0°C for 3 hours, add methanol (63.3g), then slowly drop trimethylchlorosilane (85.02g), dropwise, and react at -10°C to 0°C for 2 hours, then slowly drop Freshly prepared cyclopentadiene (50.0g), dropwise, react at -10°C to 0°C for 3 hours, then add 5% palladium carbon (10.6g), feed hydrogen into the reaction bottle, and react at room temperature at about 27°C After 3 hours, potassium hydroxide solution (0.8L, 2mol / L) was added, and the dropwise reaction was completed at room temperature for 2 hours. React at ℃ to 0℃ for 4 hours. After the reaction is completed, remove the filter residue by filtration. Add 2mol / L hydrochloric acid solution to the fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com