Production method for high-dispersity iron oxide black

A technology of iron oxide black and production method, which is applied in the field of chemical pigments, can solve the problems of poor dispersibility and limit the use range of iron oxide black, and achieve the effects of high tinting strength, expanded use occasions and purposes, and increased dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

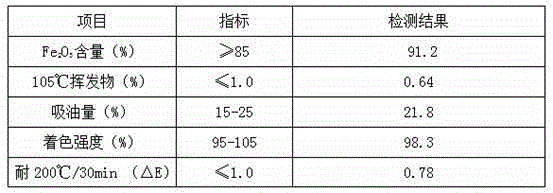

Image

Examples

Embodiment Construction

[0009] A production method of highly dispersed iron oxide black, which adopts the iron oxide black obtained by the sodium hydroxide oxidation method, directly uses the undried iron oxide black filter cake, and adds hexametaphosphoric acid equivalent to 6% of the iron oxide black filter cake Sodium, 1.5% fatty acid polyethylene glycol ester, 2500rpm high-speed grinding for 10 minutes, take out and dry, add appropriate amount of water and beat for 20 minutes to make a slurry with a concentration of 50%, and add 1,4- Butynediol, 0.3% aluminum nitride, 0.4% vanadium boride, stirred for 25 minutes, and then passed through a colloid mill to refine the particle size to less than 50 μm, and the liquid slurry was heated at a flow rate of 80 kg / hour at 350 ° C Spray drying under hot air flow into granular powder, drying and powdering is the finished product.

[0010] In the present invention, sodium hexametaphosphate and polyethylene glycol fatty acid ester are used as organic and inorg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com