Method for preparing cerium dioxide / calcium aluminum layered di-hydroxy composite metal oxide / activated carbon composite material

A layered double hydroxyl and composite metal technology, applied in chemical instruments and methods, water/sludge/sewage treatment, water pollutants, etc., can solve the problem of reducing the adsorption effect of materials, easy to block the micropores of activated carbon, and large particle size of LDHs and other problems, to achieve the effect of good adsorption effect, excellent adsorption performance, simple and fast process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

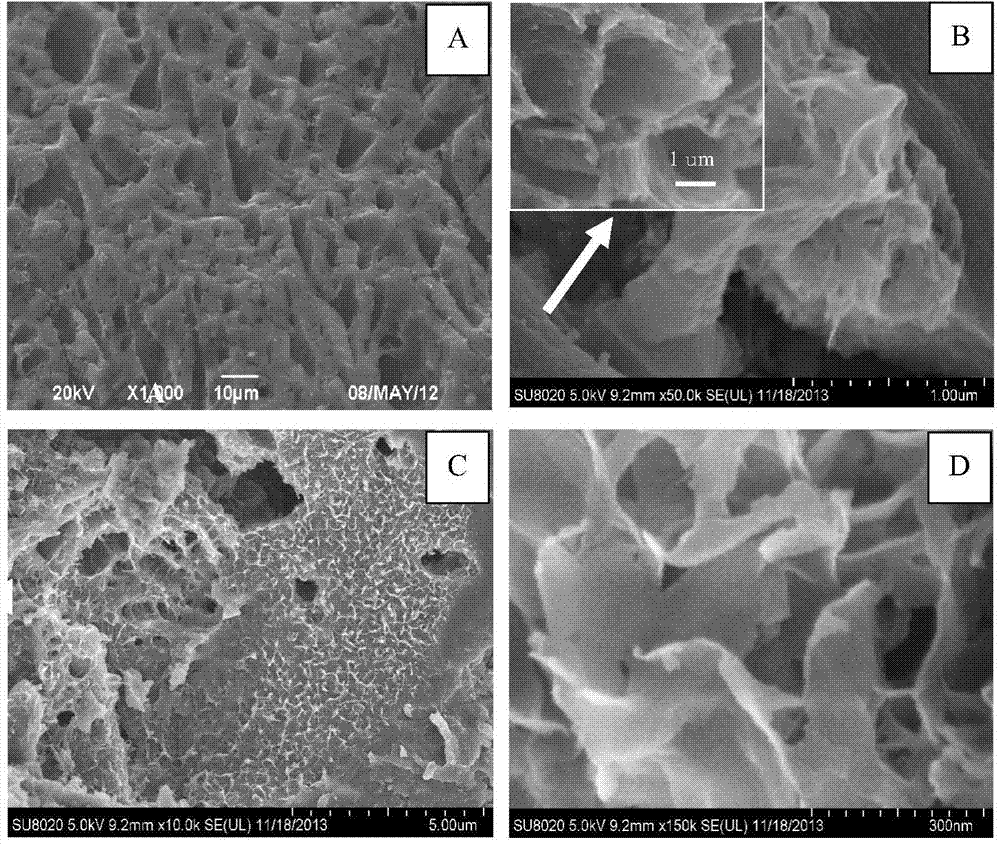

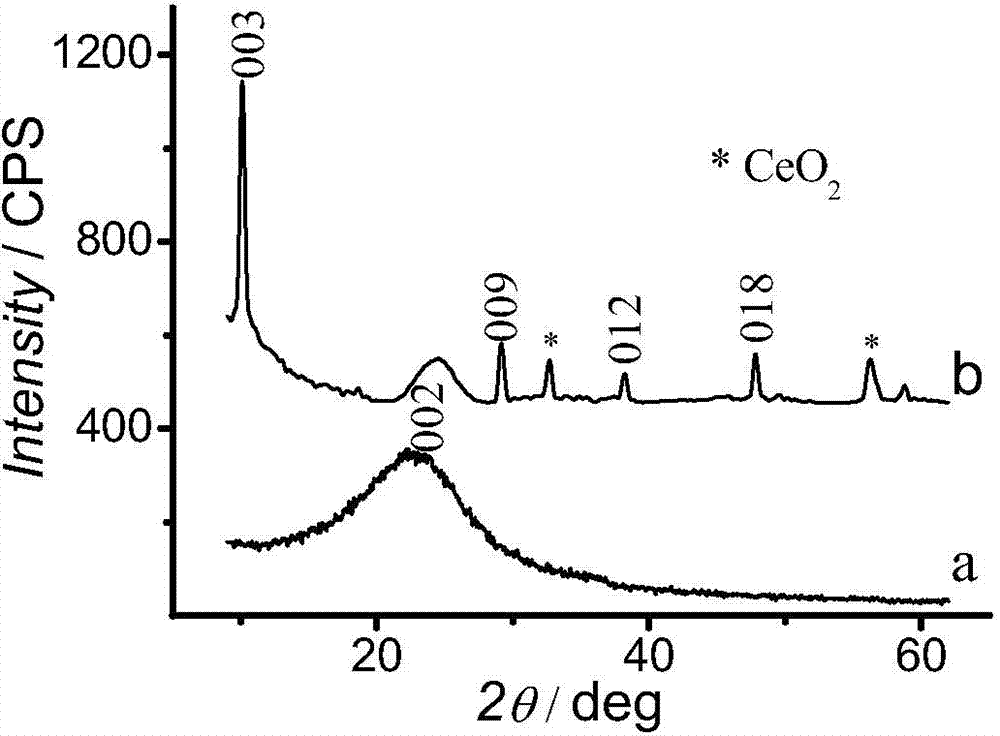

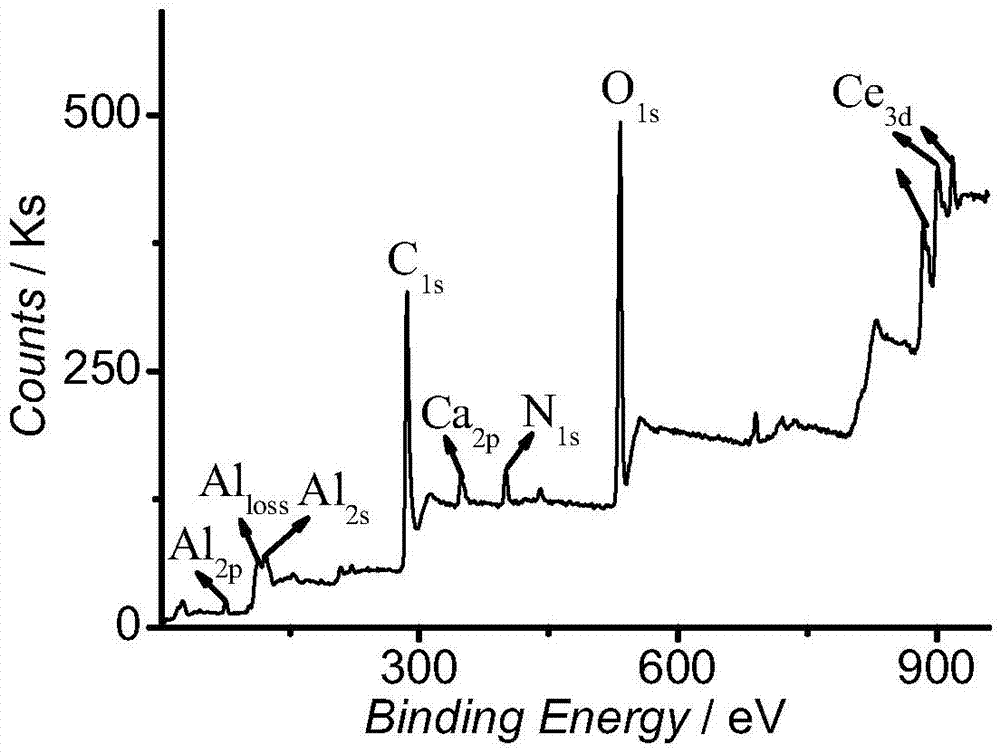

[0037] CeO in this example 2 / CaAl-LDHs / AC composites were prepared as follows:

[0038] 1) Activated carbon pretreatment

[0039] Immerse 50.0 g of activated carbon with nitric acid solution with a mass concentration of 65% at room temperature for 7 hours to eliminate surface impurities, wash and dry; immerse 10.0 g of activated carbon after nitric acid solution treatment into 50.0 mL of 0.001 mol / L tetraoxaloacetic acid solution , sonicated for 1 hour at room temperature, washed with distilled water and dried in vacuum to obtain pretreated activated carbon, denoted as AC.

[0040] 2) Preparation of composite materials

[0041] At 80°C, 10.0 g of AC was vacuum-heated-depressurized (vacuum degree 0.02 MPa) for 1 hour, then immediately added to 80.0 mL of mixed solution B, and the pH value was adjusted to 9.3 by 1.0 mol / L NaOH solution. Then ultrasonically assisted co-precipitation under the conditions of ultrasonic power 60W and temperature 30°C for 1 hour, and finally aged...

Embodiment 2

[0045] CeO in this example 2 / CaAl-LDHs / AC composites were prepared as follows:

[0046] 1) Activated carbon pretreatment

[0047] 50.0 g of activated carbon was soaked with a nitric acid solution with a mass concentration of 65% at room temperature for 7 hours to eliminate surface impurities, washed and dried; the activated carbon after 5.0 g of the nitric acid solution was immersed in 50.0 mL of 0.01 mol / L diaminoacetic acid solution, Sonicate at room temperature for 2 hours, take it out, wash it with distilled water and dry it in vacuum to obtain pretreated activated carbon, denoted as AC.

[0048] 2) Preparation of composite materials

[0049] At 100°C, 5.0g AC was subjected to vacuum-heating-decompression (vacuum degree 0.08MPa) treatment for 2 hours, then immediately added to 100.0mL mixed solution B, and the pH value was adjusted to 7.5 by 1.0mol / L NaOH solution, Then ultrasonically assisted co-precipitation under the conditions of ultrasonic power 40W and temperatur...

Embodiment 3

[0053] CeO in this example 2 / CaAl-LDHs / AC composites were prepared as follows:

[0054] 1) Activated carbon pretreatment

[0055] Immerse 50.0 g of activated carbon with nitric acid solution with a mass concentration of 65% at room temperature for 7 hours to eliminate surface impurities, wash and dry; immerse 20.0 g of activated carbon after nitric acid solution treatment into 100.0 mL of 0.002 mol / L ethylenediaminetetraoxalyl In acetic acid solution, ultrasonic at room temperature for half an hour, take out, wash with distilled water and dry in vacuum to obtain pretreated activated carbon, denoted as AC.

[0056] 2) Preparation of composite materials

[0057] At 100°C, 20.0g AC was subjected to vacuum-heating-decompression (vacuum degree 0.05MPa) treatment for 2 hours, then immediately added to 100.0mL mixed solution B, and the pH value was adjusted to 7.5 by 1.0mol / L NaOH solution, Then ultrasonically assisted co-precipitation under the conditions of ultrasonic power 90W...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Maximum adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com