Extraction method of algae iodate and composite algae iodate salt additive

An extraction method, seaweed iodine technology, applied in chemical instruments and methods, food science, inorganic chemistry, etc., can solve the problems of excessive heavy metal residues and high production costs, achieve less extraction agent consumption, large mass transfer power, and reduce production cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

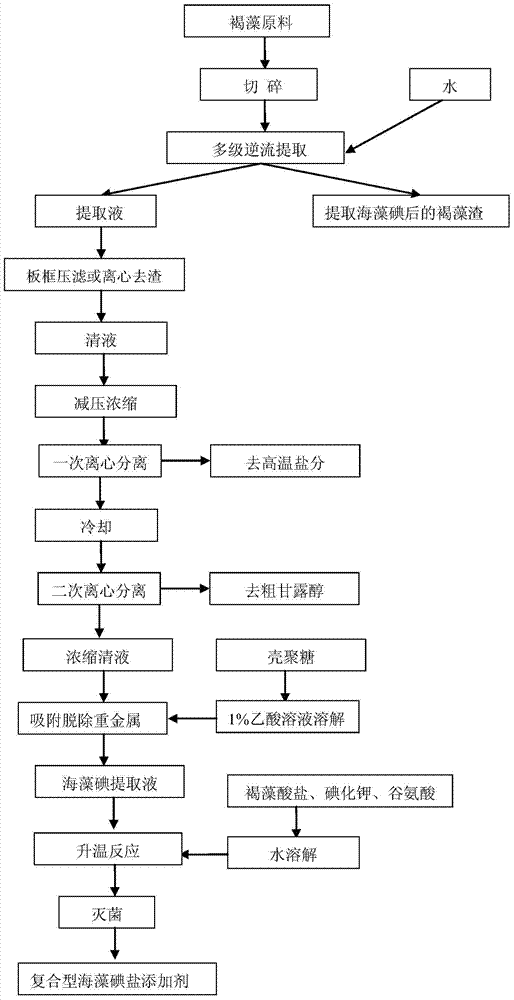

[0038] A kind of extracting method of seaweed iodine, specific technological process sees figure 1 ,Specific steps are as follows:

[0039] ① Dried kelp 300kg, cut into strips of 2-5 cm with a vegetable cutter, evenly divided into 3 parts and loaded into 3 pieces of 1.2m each 3 In the extraction tank, add 1000L water in the first tank, mix and extract at room temperature for 0.5 hour, and filter to obtain the filtrate. Then follow the operation procedure of 3-stage counter-current extraction to carry out counter-current immersion extraction operation sequentially, realize the reverse operation of the extraction phase and the raffinate phase through the reverse transfer of the extracted aqueous solution, contact mass transfer step by step, and finally extract the liquid from the first stage, that is, kelp. The raffinate phase, that is, the extracted kelp extraction slag, is discharged from the last stage, that is, the addition tank of the extracted water.

[0040] ②For the ex...

Embodiment 2

[0050] ①Take 300kg of sargassum, cut it into small pieces of about 5cm with a vegetable cutter, and then divide it into 3 parts and put them into 3 pieces of 1.2m 3 In the extraction tank, add 1000L water to the first tank, mix and extract at room temperature for 0.5-2.0 hours, and filter to obtain the filtrate. Then follow the operation procedure of 3-stage countercurrent extraction to carry out countercurrent immersion extraction operation sequentially, realize the reverse operation of the extraction phase and the raffinate phase through the reverse transfer of the extracted aqueous solution, contact mass transfer step by step, and finally extract the liquid from the first stage, that is, Sargassum It is discharged from the feeding tank, and the residue phase, that is, the extracted Sargassum extract residue, is discharged from the last stage, that is, the adding tank of the extracted water.

[0051] ②For the extract obtained in step ①, use plate-and-frame filter press or ce...

Embodiment 3

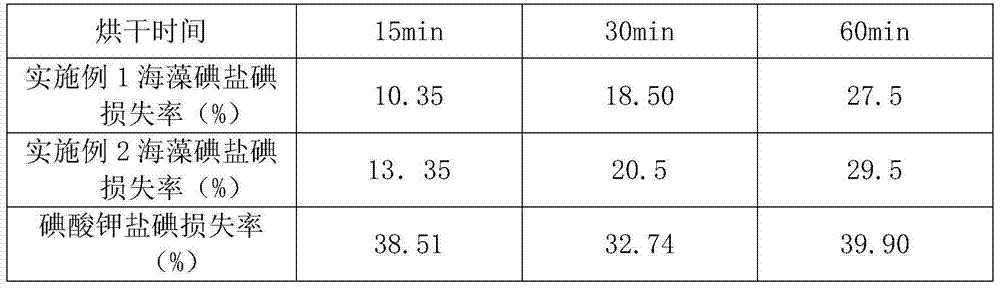

[0055] The composite seaweed iodized salt additive and potassium iodate obtained in the above-mentioned Examples 1 and 2 were added to table salt respectively according to the iodized salt production method, to prepare seaweed iodized salt and iodized salt containing potassium iodate.

[0056] Weigh 50g of two iodized salts respectively, put them into crucibles, conduct heating tests at 100°C and 250°C respectively, take samples at 15min, 30min, and 60min respectively, and measure the amount of iodine in the heating process according to the national standard GB10325.7 Loss rate, determine the iodine loss rate and thermal stability of seaweed iodized salt after heating. The experimental results are shown in Table 1 and Table 2 respectively.

[0057] Table 1 Comparison of heat loss rate between seaweed iodized salt and potassium iodate salt at 100℃

[0058] Table 2 Comparison of heat loss rate between seaweed iodized salt and potassium iodate salt at 250℃

[0059]

[0060...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com