Method for preparing near-infrared carbon quantum dots using magenta as carbon source

A carbon quantum dot and infrared carbon technology, which is applied in the field of preparing near-infrared carbon quantum dots, can solve the problems of pollution, waste of resources and the environment, etc., and achieve the effects of reducing pollution, protecting the environment and shortening the reaction time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] a. Weigh 1.00 g of the turmeric extract residue after constant drying in a drying oven at 105°C for 2 hours and put it into a 50mL hydrothermal reaction kettle, add 40mL of secondary water, place it in a drying oven, and adjust the reaction temperature to 200°C. The reaction time is 2 hours. After the reaction, take out the reaction kettle, place it on a porcelain plate, let it cool down to room temperature naturally, then open the reaction kettle, filter the product in the kettle, and obtain a carbon quantum dot stock solution with a fluorescence emission peak at 520nm ;

[0018] b. Weigh 0.01507g fuchsin and dissolve it in a 50mL volumetric flask to obtain a concentration of 1.0×10 -3 The fuchsin solution of mol / L is used as stock solution;

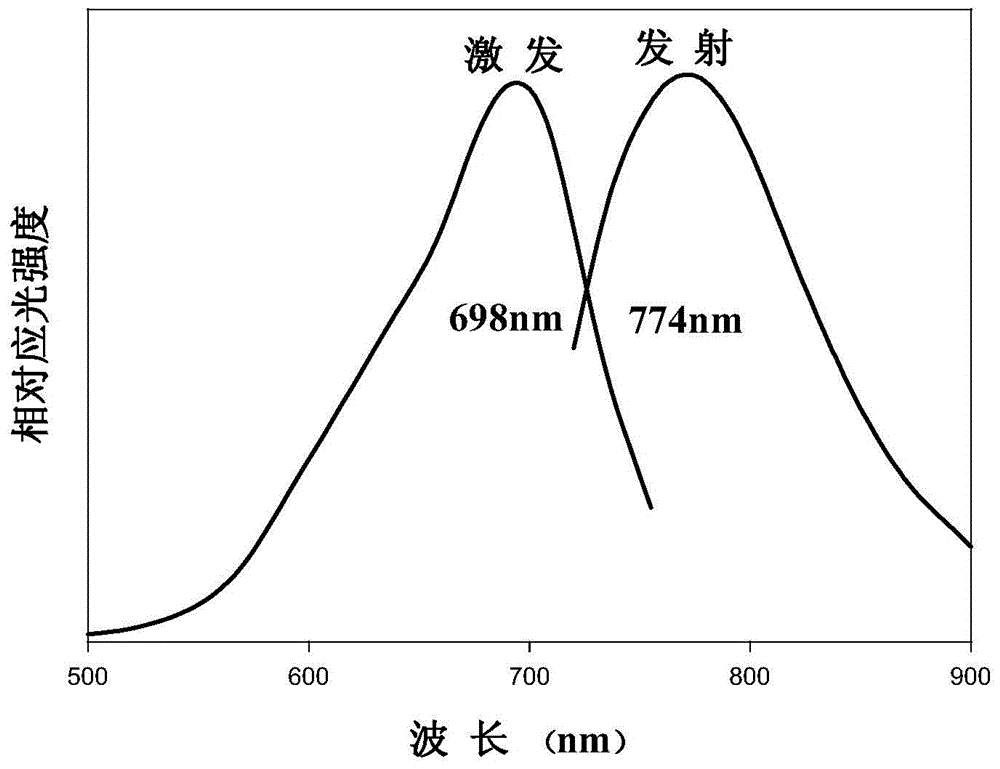

[0019] c. Add 1mL of the magenta solution prepared in step (2) and the carbon quantum dot solution prepared in 1mL of step (1) into a 50mL reactor, add 38mL of secondary water, place in a drying oven, adjust the reaction tempera...

Embodiment 2

[0022] a. Weigh 1.00g of turmeric extract residue after constant drying in a 105°C drying oven for 2h, put it in a 50mL hydrothermal reaction kettle, add 40mL of secondary water, put it in a drying oven, and adjust the reaction temperature to 200°C , the reaction time is 2 hours. After the reaction, take out the reaction kettle, place it on a porcelain plate, let it cool down to room temperature naturally, then open the reaction kettle, filter the product in the kettle, and obtain a carbon quantum dot reserve with a fluorescence emission peak at 520nm liquid;

[0023] b. Weigh 0.01507g fuchsin and dissolve it in a 50mL volumetric flask to obtain a concentration of 1.0×10 -3 The fuchsin solution of mol / L is used as stock solution;

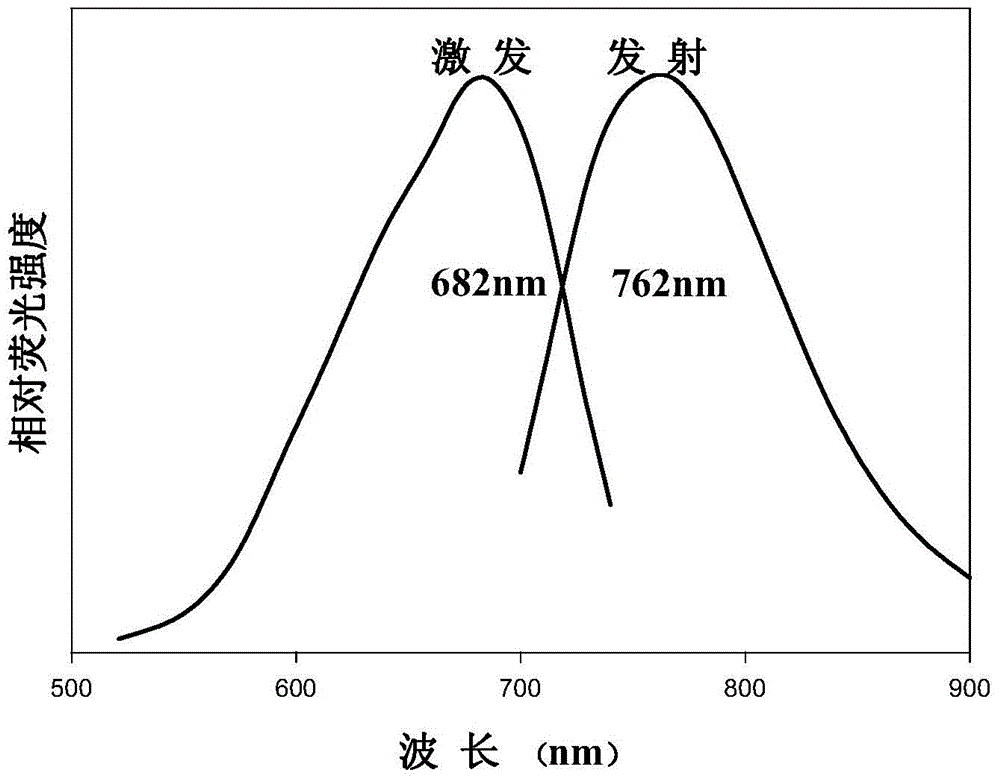

[0024] c. Add 1mL of the magenta solution prepared in step (2) and the carbon quantum dot solution prepared in 2mL of step (1) into a 50mL reactor, add 37mL of secondary water, place it in a drying oven, and adjust the reaction temperature to 220°C...

Embodiment 3

[0027] a. Weigh 1.00g of turmeric extract residue after constant drying in a 105°C drying oven for 2h, put it in a 50mL hydrothermal reaction kettle, add 40mL of secondary water, put it in a drying oven, and adjust the reaction temperature to 200°C , the reaction time is 2 hours. After the reaction, take out the reaction kettle, place it on a porcelain plate, let it cool down to room temperature naturally, then open the reaction kettle, filter the product in the kettle, and obtain a carbon quantum dot reserve with a fluorescence emission peak at 520nm liquid;

[0028] b. Weigh 0.01507g fuchsin and dissolve it in a 50mL volumetric flask to obtain a concentration of 1.0×10 -3 The fuchsin solution of mol / L is used as stock solution;

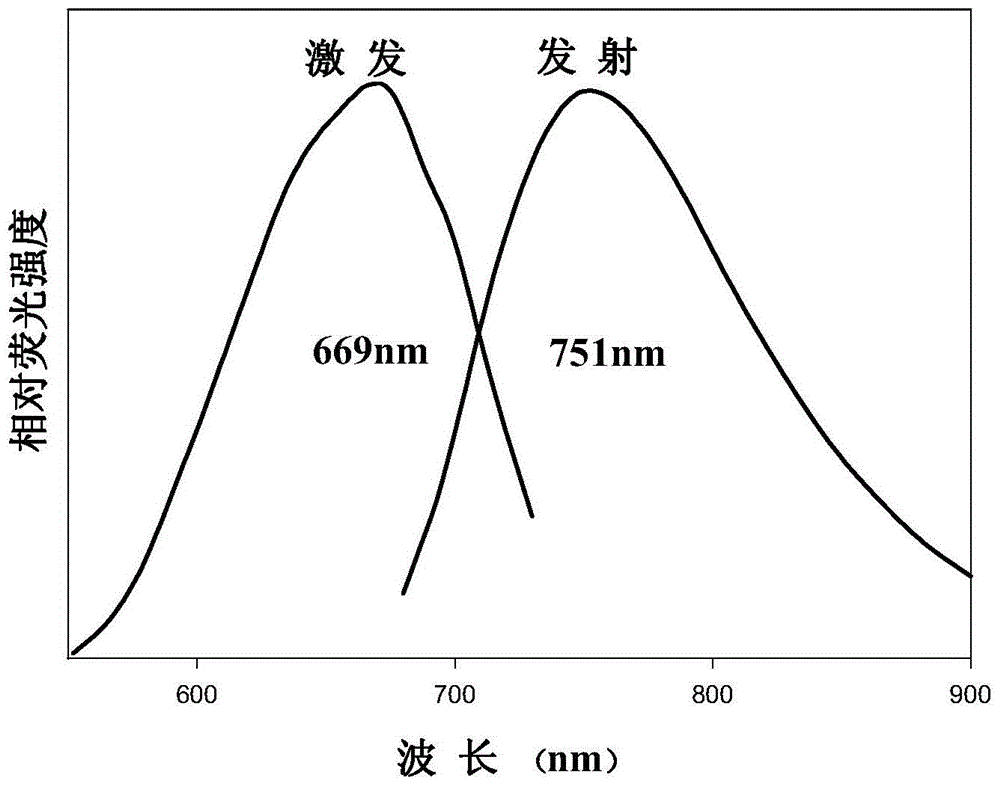

[0029] c. Add 1mL of fuchsin solution and 3mL of carbon quantum dot solution into a 50mL reactor, add 36mL of secondary water, place in a dry box, adjust the reaction temperature to 220°C, and react for 4 hours. After the reaction, take out the rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com