Method and device for producing methane-enriched gas from carbon-containing raw materials

A technology for methane gas and raw materials, which is applied in the field of producing methane-rich gas, can solve the problems of increased process cost, high raw material pretreatment cost, complicated equipment and process, etc. Effects of catalyst sintering and coke deactivation mitigation, reducing equipment and operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

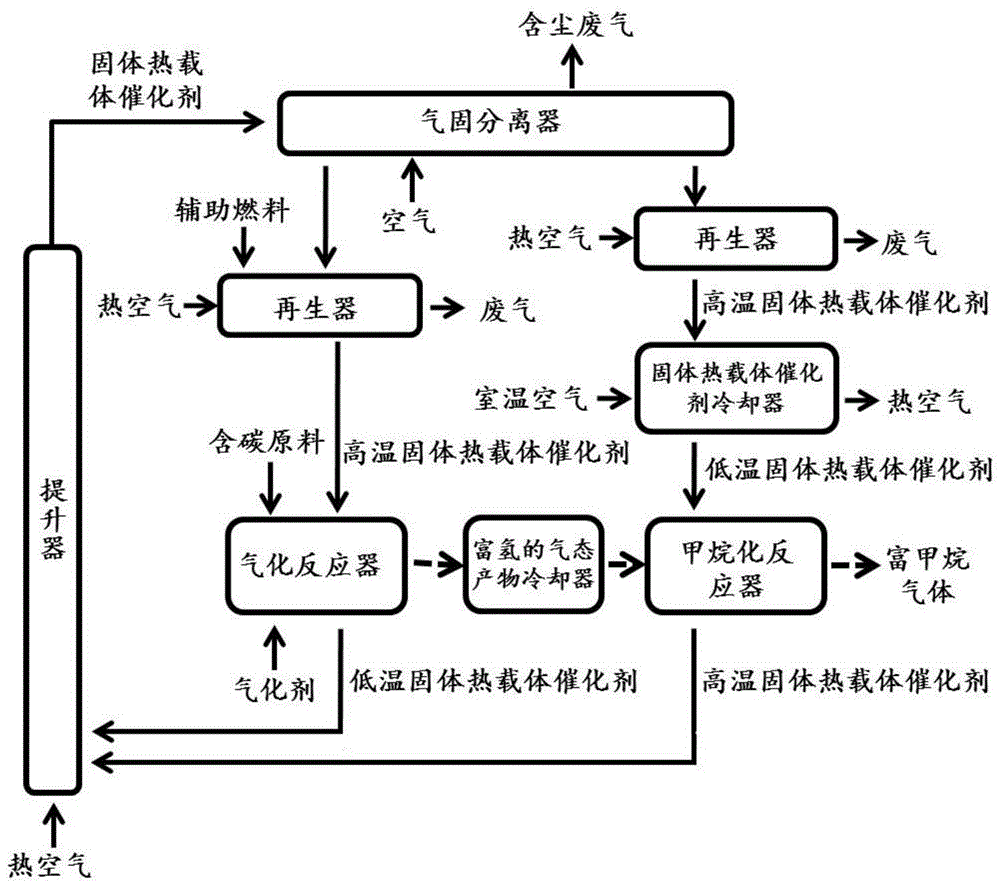

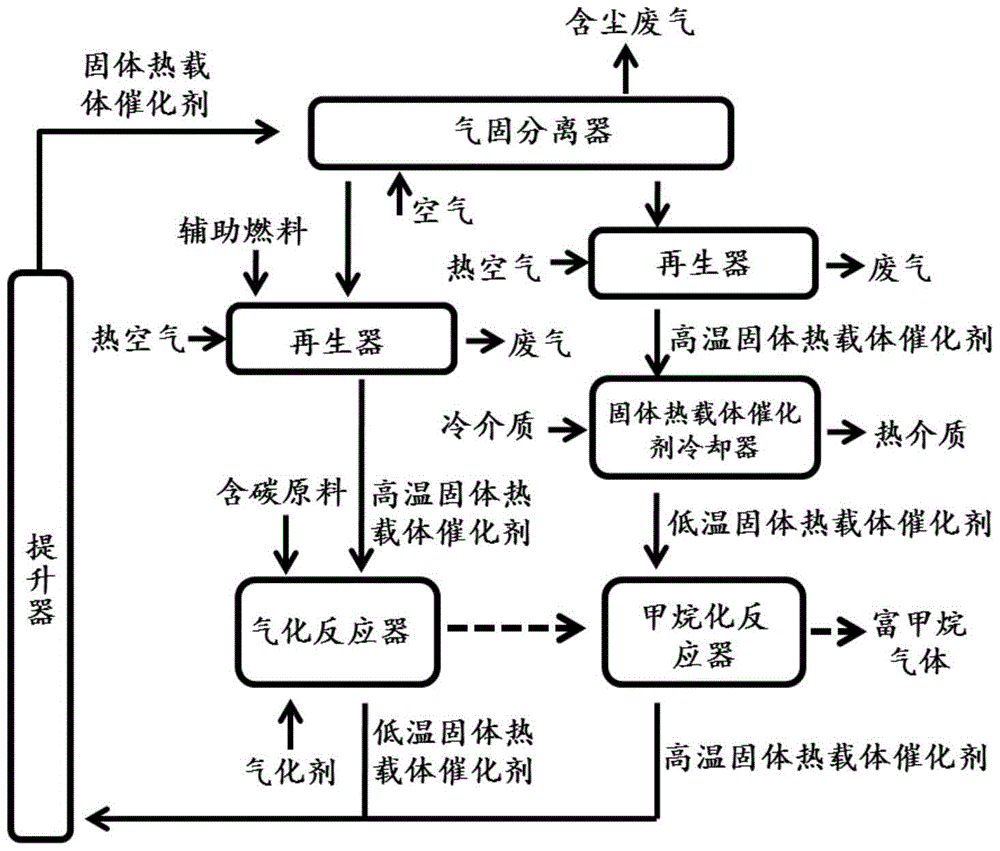

[0031] In the experimental system with a raw material handling capacity of 1kg / h, the co-processing of white pine sawdust and lignite to produce methane-enriched gas was carried out. The operating procedure of the experimental system is attached figure 2 . The air-drying basis moisture, air-drying basis volatile matter and particle size of the first raw material white pine sawdust and the second raw material lignite are 5.0%, 77.7%, less than 2mm and 27.9%, 35.1%, less than 1.2mm respectively. Before the experiment, the raw materials were dried in an oven at 105-110°C for 3 hours. The dual-function catalyst particles (NiO mass fraction: 7%) supported by olivine with a particle size of 0.2-1.2 mm for reforming and methanation are used as a circulating solid heat carrier catalyst. The feeding rate of white pine and lignite is 250g / h, the circulation rate of the solid heat carrier catalyst entering the gasification reactor is 15kg / h, and the circulation rate of the solid heat c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com