A kind of molten steel purifying agent in the form of composite sphere and its production method

A purifying agent and sphere technology, which is applied in the field of molten steel purifying agent, purification and refining of liquid non-ferrous metals, and can solve problems such as affecting the efficiency of composite spheres.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

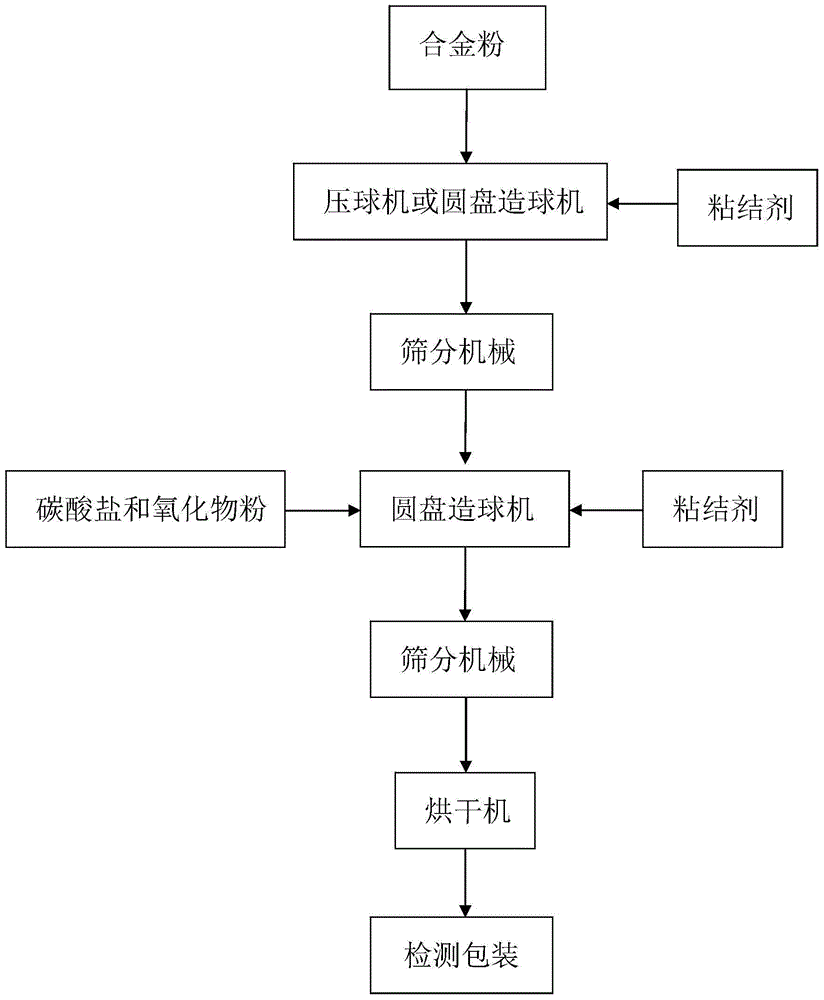

Method used

Image

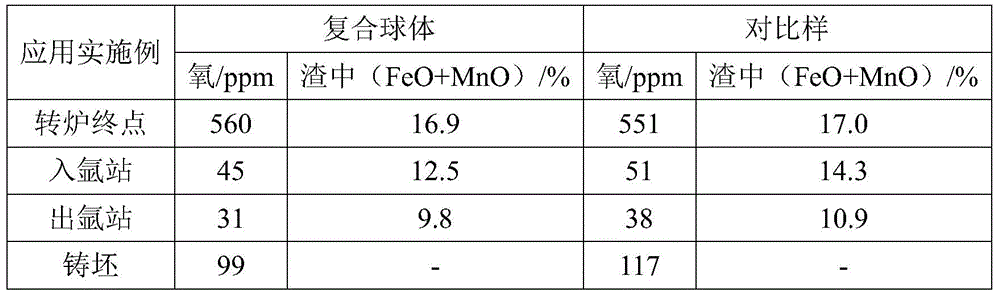

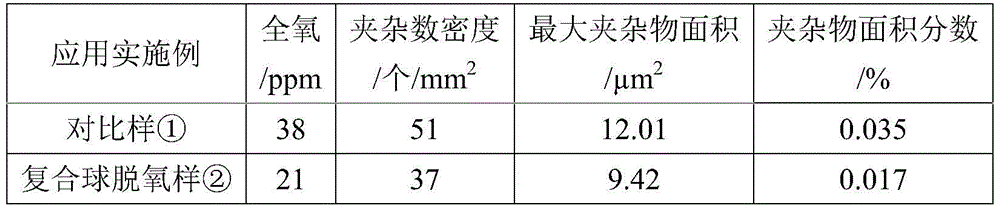

Examples

Embodiment 1

[0044] Use 200kg of aluminum powder (Al: 99.5%, particle size less than 3mm), 200kg of ferrosilicon (Si: 75%, Al 2.0%, Ca1.5%, C: 0.1%, S: less than 0.02%, P: less than 0.04%, Fe balance, particle size less than 3mm), high carbon ferromanganese 470kg (Mn: 65%, C: 6.0%, Si: 2.5%, S: less than 0.03%, P: less than 0.38%, Fe balance, particle size less than 3mm) , Alkaline sodium silicate solution (modulus 3.4, Baume degree 40) 35kg puts into the mixer together and stirs for 20 minutes, after the evenly stirred material goes through the belt conveyor to the hoist, it is evenly added into the ball press machine to be pressed into balls, passed The size of the spheres is controlled and determined by sieving to obtain a spherical nucleus with a diameter of 10±0.5mm. Limestone powder (CaCO 3 : greater than 98%, particle size less than 1mm) 600kg and calcium oxide powder (CaO: greater than 90%, particle size less than 1mm) 600kg as jersey materials, the activity of calcium oxide is mo...

Embodiment 2

[0046] Use 200kg of aluminum powder, 200kg of ferrosilicon, 470kg of high-carbon ferromanganese (requirements such as above-mentioned material composition and particle size are the same as embodiment 1, the same below) and drop into mixer together and stir for 20 minutes, after the material after stirring is through belt conveyor, equably A disc pelletizing machine is added, and the rotating speed of the pelletizing machine is 400-1200r / min. Spray into alkaline sodium silicate solution, the solution quality is 3% of alloy powder quality. After pelletizing, the size of the pellets is controlled and determined by sieving, and the pellets are used as pellet cores with a diameter of 10±0.5mm. Take 600kg of limestone powder and 600kg of calcium oxide powder as jersey materials, and fully mix them in a mixer for 1 to 2 hours. In the disc pelletizer, add jersey material, spray limestone powder and a binder with a mass fraction of calcium oxide of 3%, roll and pelletize to form a com...

Embodiment 3

[0048] Use 2kg of aluminum powder, 2kg of ferrosilicon, 4.70kg of low-carbon ferromanganese, and 0.3kg of alkaline sodium silicate solution to press to prepare spherical cores. The method is the same as in Example 1. The powder required for the jersey is 6kg of light calcium carbonate, 6kg of calcium oxide and 0.6kg of calcium aluminate cement binder, which are fully mixed in the mixer, and the pellets are sent to the disc pelletizer, and the jersey powder is added , spray an appropriate amount of water not exceeding 2% of the mass of the powder, the speed of the disc pelletizer is 400-1200r / min, and roll to form composite spheres. Composite spheres with a size of 15±0.5mm and a residual moisture of no more than 0.5% were obtained by sieving. Dry the composite sphere at 110-120°C for 4 hours. The compressive strength of the composite sphere is greater than 2000N, and the drum index is greater than 90%. Cool to room temperature, test the composition and strength, and use it wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| water activity | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com