Nano compound function fibers as well as preparation method and application thereof

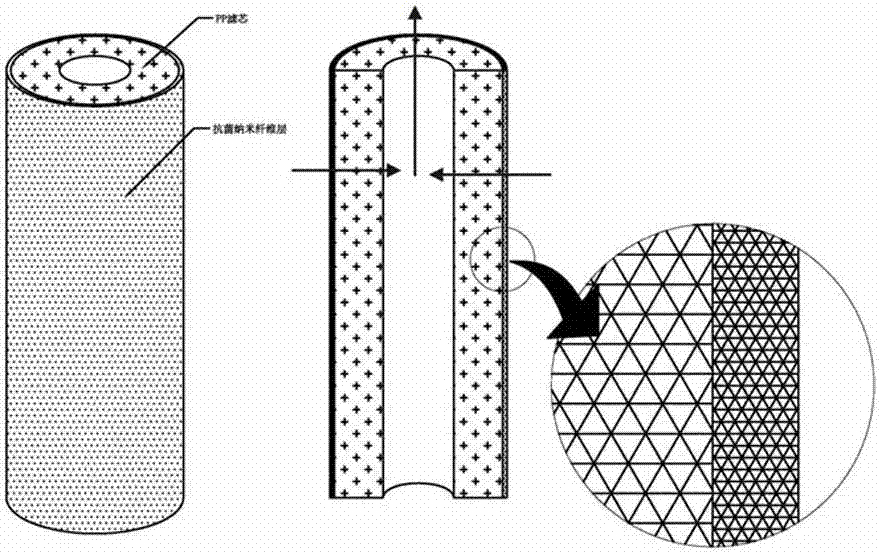

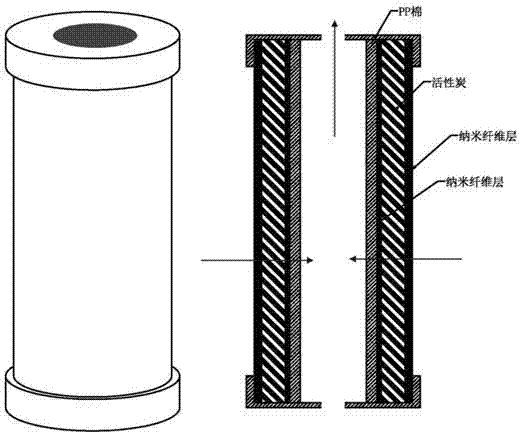

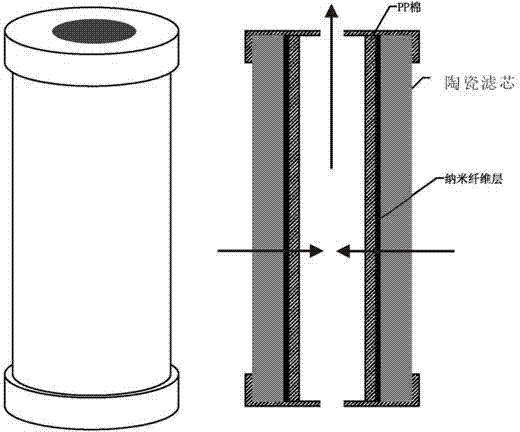

A functional fiber and nano-composite technology, applied in the chemical characteristics of fibers, chemical instruments and methods, cellulose/protein conjugated rayon, etc., can solve the problems of impurity clogging, poor filtering effect, etc., and increase the filtering efficiency. , The effect of enhancing the strength of the filter element and improving the filtration accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A nanocomposite functional fiber, in parts by weight, its raw materials include: 25 parts of biodegradable materials mixed with polylactic acid and gelatin in a mass ratio of 3:1, Al 2 o 3 10 parts, 3 parts of silane coupling agent, 60 parts of organic polymer materials mixed with polyethylene oxide and polyvinylpyrrolidone in a mass ratio of 15:1, 3 parts of nano far-infrared ceramic powder, 0.08 part of zinc chloride, 1 carotenoid part, 0.3 part of calcium carbonate.

[0029] The preparation method is:

[0030] 1)Al 2 o 3 Pulverize with a superfine pulverizer, pass through a 1000-mesh sieve, then mix evenly with the silane coupling agent, let stand for 15-20min, and set aside;

[0031] 2) The calcium carbonate is pulverized by an ultrafine pulverizer, passed through a 1000-mesh sieve, and set aside;

[0032] 3) Heat the mixed material of polyethylene oxide and polyvinylpyrrolidone to a molten state, keep it warm, and add Al which has been treated in step 1) 2 o ...

Embodiment 2

[0043] A nanocomposite functional fiber, in parts by weight, its raw materials include: 12 parts of biodegradable materials mixed with gelatin and chitosan in a mass ratio of 20:1, TiO 2 , SiO 2 、Al 2 o 3 15 parts of inorganic materials mixed at a mass ratio of 5:23:17, 5 parts of silane coupling agents, 60 parts of organic materials mixed with polyvinylidene fluoride and polyvinylpyrrolidone at a mass ratio of 17:1, nanometer far-infrared ceramic powder 1 part, 0.05 part of copper chloride, 1 part of carotenoid, 0.5 part of calcium carbonate.

[0044] The preparation method is:

[0045] 1) Inorganic materials are pulverized with a superfine pulverizer, passed through a 1000-mesh sieve, then mixed with a silane coupling agent evenly, and left to stand for 15-20 minutes for later use;

[0046] 2) The calcium carbonate is pulverized by an ultrafine pulverizer, passed through a 1000-mesh sieve, and set aside;

[0047] 3) Heat the organic polymer material to a molten state, k...

Embodiment 3

[0059] A nanocomposite functional fiber, in parts by weight, whose raw materials include: 18 parts of biomacromolecule degradable materials mixed with gelatin, polylactic acid, and polyε-caprolactone at a mass ratio of 15:7:2, ZrO 210-15 parts of inorganic materials mixed with ZnO at a mass ratio of 18:7, 3-5 parts of a silane coupling agent, and organic polymers mixed with polyaramid, polyurethane, and polystyrene at a mass ratio of 30:4:13 65 parts of materials, 2 parts of nanometer far-infrared ceramic powder, 0.07 part of copper nitrate, 0.5 part of carotenoid, and 0.25 part of calcium carbonate.

[0060] The preparation method is:

[0061] 1) Inorganic materials are pulverized with a superfine pulverizer, passed through a 1000-mesh sieve, then mixed with a silane coupling agent evenly, and left to stand for 18 minutes for later use;

[0062] 2) The calcium carbonate is pulverized by an ultrafine pulverizer, passed through a 1000-mesh sieve, and set aside;

[0063] 3) He...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wire diameter | aaaaa | aaaaa |

| Spray thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com