Photoelectrochemical kinetics test system and method based on scanning electrochemical microscope

A scanning electrochemistry and photoelectrochemistry technology, applied in measurement devices, scientific instruments, instruments, etc., can solve the problems of cumbersome experimental operation and data analysis, imperfect information capture technology, and unclear mechanism, and achieve simple data processing steps. Clear, conducive to promotion and application, easy to control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

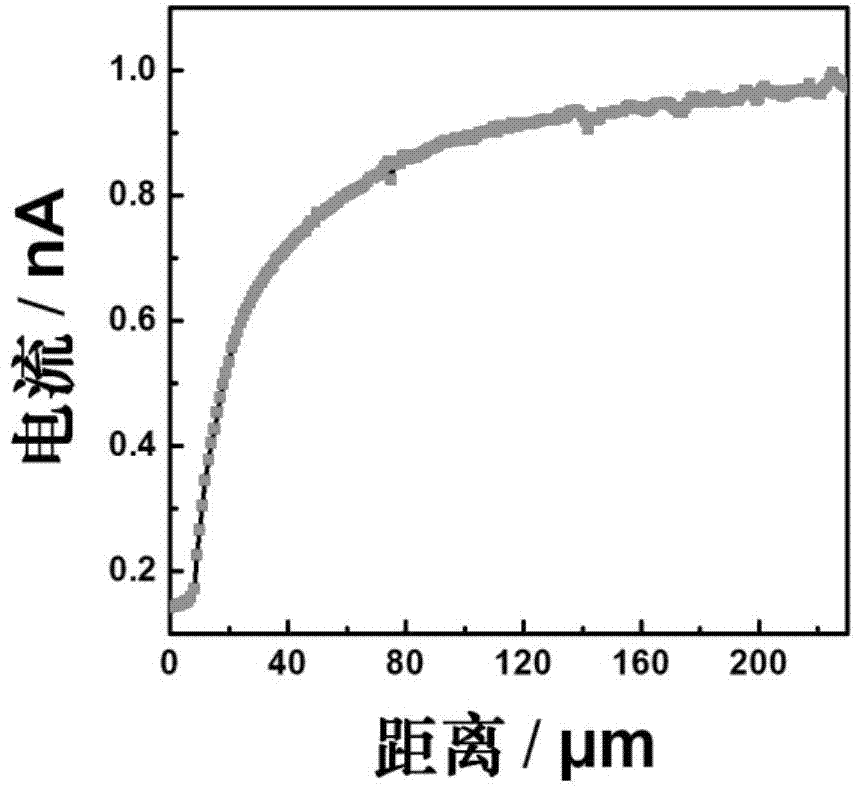

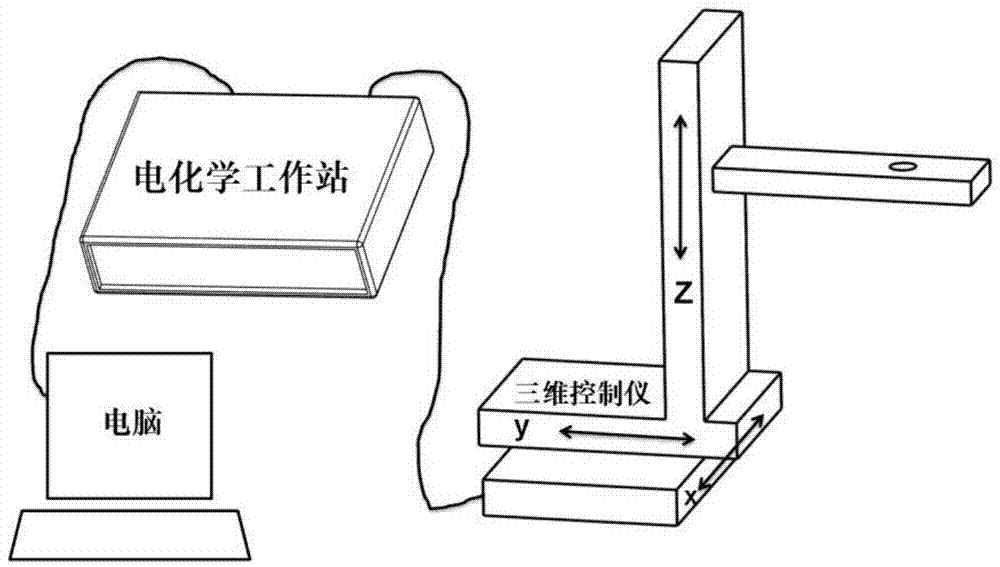

[0042] In this embodiment, the photoelectrochemical kinetics testing method based on scanning electrochemical microscope comprises the following steps:

[0043] S1. Preparation of redox electrolyte. In this embodiment, the cobalt electrolyte Co(bpy) 3 (PF 6 ) 3 As an example, take acetonitrile CH 3 CN is the solvent, tetrabutylammonium perchlorate C 16 h 36 ClNO 4 For the supporting electrolyte, prepare cobalt electrolyte Co(bpy) with a series of concentrations of 1mM, 0.8mM, 0.6mM, 0.3mM, 0.1mM and 0.03mM respectively 3 (PF 6 ) 3 For the redox electrolyte, take 2mL electrolyte with a certain concentration each time and add it to the PTFE reaction cell;

[0044] S2. Prepare the base electrode. P25 TiO 2 The paste was prepared by screen printing onto the conductive glass FTO to form TiO 2 thin film, then annealed in an annealing furnace at 500°C for 30 minutes and then cooled naturally. When the temperature dropped to 80°C, the FTO / TiO 2 The film was soaked into th...

Embodiment 2

[0054] In this embodiment, the photoelectrochemical kinetics testing method based on scanning electrochemical microscope comprises the following steps:

[0055] S1. Preparation of redox electrolyte. In this example, the polysulfide electrolyte T 2 As an example, take acetonitrile CH 3 CN is the solvent, tetrabutylammonium perchlorate C 16 h 36 ClNO 4 For the supporting electrolyte, prepare 1mM, 0.6mM, 0.3mM, 0.1mM, a series of concentrations of polysulfide electrolyte T 2 For the redox electrolyte, take 2mL electrolyte of a specific concentration and fill it into the PTFE reaction cell each time;

[0056] S2. Preparation of the base electrode. P25 TiO 2 The paste was prepared by screen printing onto conductive glass FTO to form TiO with a diameter of 7mm 2 The film was then annealed in an annealing furnace at 500°C for 30 minutes and cooled naturally. Obtaining FTO / TiO by Ion Adsorption 2 / CdSe thin film, at this time the photoanode thin film preparation of quantum d...

Embodiment 3

[0066] In this embodiment, the photoelectrochemical kinetics testing method based on scanning electrochemical microscope comprises the following steps:

[0067] S1. Preparation of redox electrolyte. In this embodiment, potassium ferricyanide K 3 Fe(CN) 6 For example, with deionized water as solvent, sodium sulfate Na 2 SO 4 For supporting electrolyte, prepare potassium ferricyanide K with a series concentration of 4.0mM, 2.0mM, 0.6mM, 0.3mM, 0.1mM 3 Fe(CN) 6 For the redox electrolyte, take 2mL of the electrolyte with the above concentration and add it to the PTFE reaction cell;

[0068] S2. Preparation of the base electrode. The conductive glass FTO was used as the base electrode, and bismuth nitrate Bi(NO 3 ) 3 , potassium iodide KI and p-benzoquinone C 6 h 4 o 2 The aqueous solution is used as the electrolyte, and the potential of the substrate electrode is set to -0.1V by electrochemical constant potential deposition method, and the FTO / BiOI electrode is obtained...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com