Preparation method of visible-light-driven photocatalyst nano spherical MoSe2 material

A catalyst and visible light technology, applied in the field of nanomaterials, can solve the problems of wide size range, low purity, low product yield, etc., and achieve the effects of safety and environmental protection, high purity and good crystallinity in the production process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The visible light catalyst nano-spherical MoSe provided in this example 2 The preparation method of the material is as follows: 0.02mol Na 2 MoO 4 Disperse in 25mL of water, stir continuously to form a clear solution, dissolve 0.04mol of organic selenium source—sodium selenocyanoacetate in 25mL of ethylene glycol in another beaker; mix the two at room temperature, and magnetically Stir for 30 minutes to make it evenly mixed, then transfer it to a 100mL autoclave, and react at 210°C for 24 hours; centrifuge the product obtained after the reaction at a centrifugal speed of 7000rpm for 5 minutes, pour off the upper layer solution, and obtain The lower precipitate was washed with water and ethanol at least 3 times; the washed product was vacuum-dried overnight, and then annealed in a vacuum tube furnace at 450°C for 10 hours to obtain a visible light catalyst nano-spherical MoSe 2 Material.

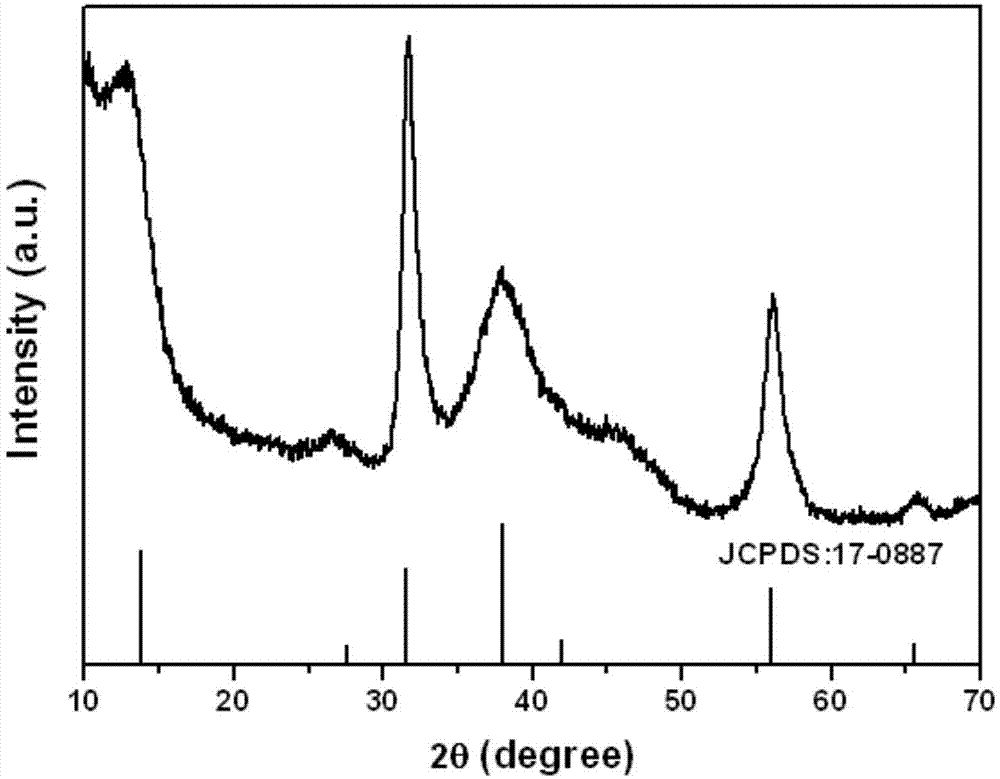

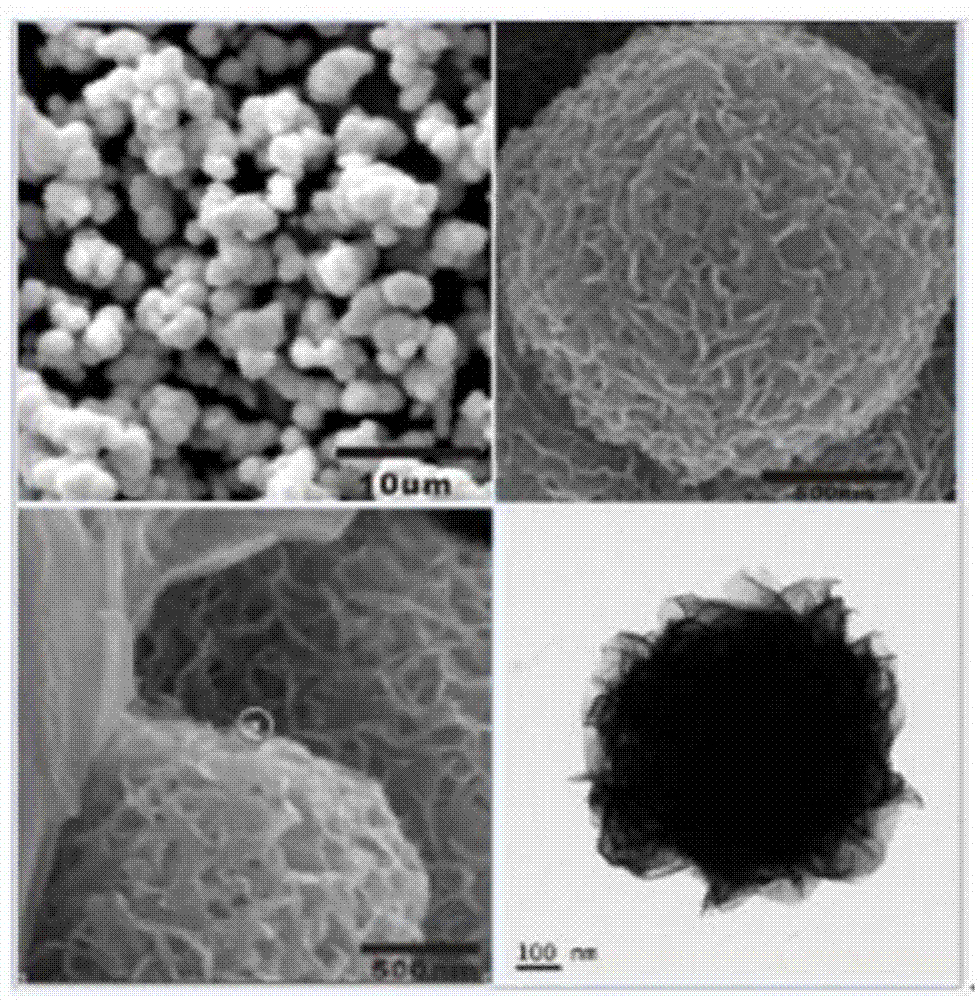

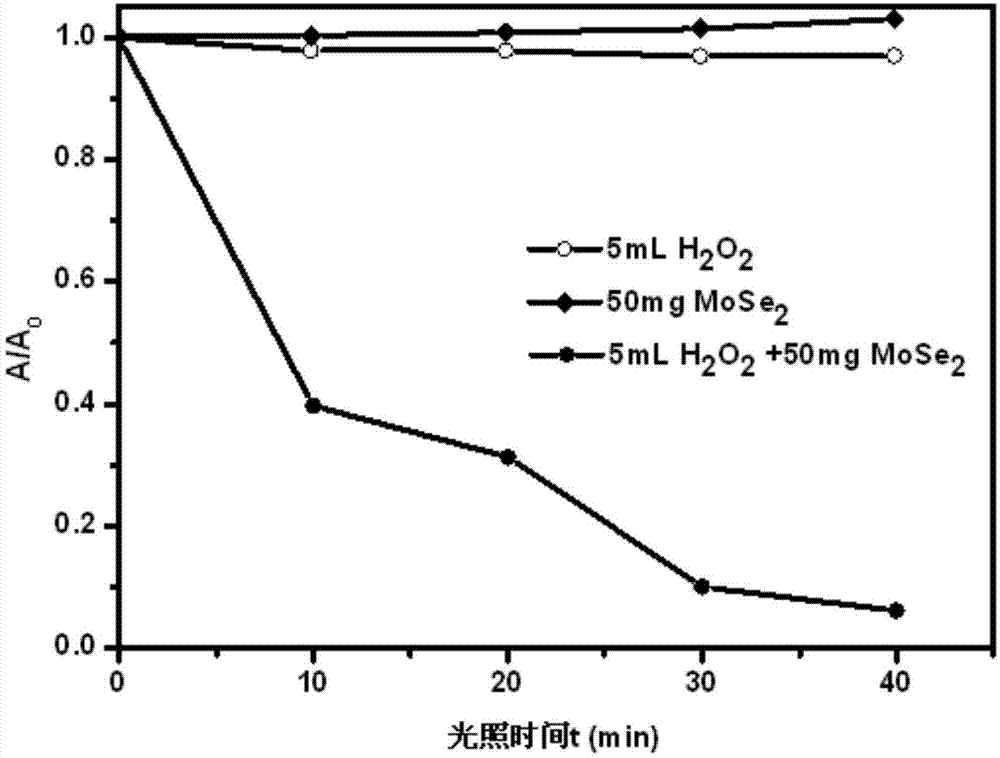

[0022] attached figure 1 It is the X-ray diffraction (XRD) pattern of the prod...

Embodiment 2

[0031] The visible light catalyst nano-spherical MoSe provided in this example 2 The preparation method of the material is as follows: 0.03mol Na 2 MoO 4Disperse in 25mL of water, stir continuously to form a clear solution, dissolve 0.09mol of organic selenium source—sodium selenocyanoacetate in 25mL of ethylene glycol in another beaker; mix the two at room temperature, and magnetically Stir for 30 minutes to make it evenly mixed, then transfer it to a 100mL autoclave, and react at 180°C for 65 hours; centrifuge the product obtained after the reaction at a centrifugal speed of 7000rpm for 5 minutes, pour off the upper layer solution, and obtain The lower precipitate was washed with water and ethanol at least 3 times; the washed product was vacuum-dried overnight, and then annealed in a vacuum tube furnace at 350°C for 12 hours to obtain a visible light catalyst nano-spherical MoSe 2 Material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com