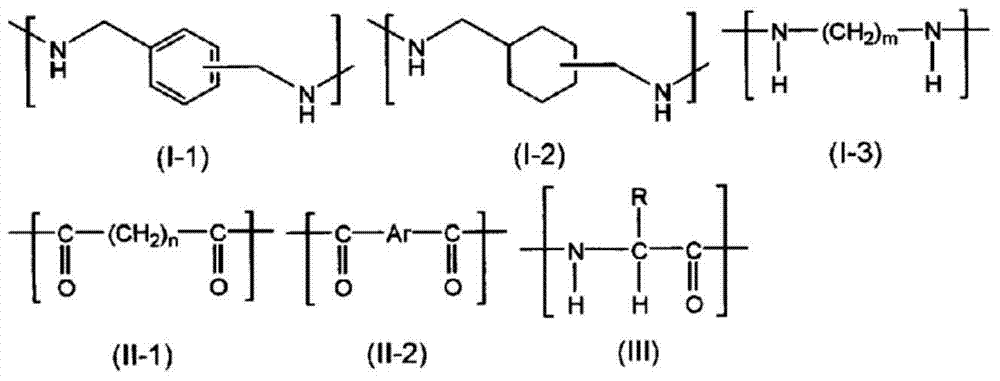

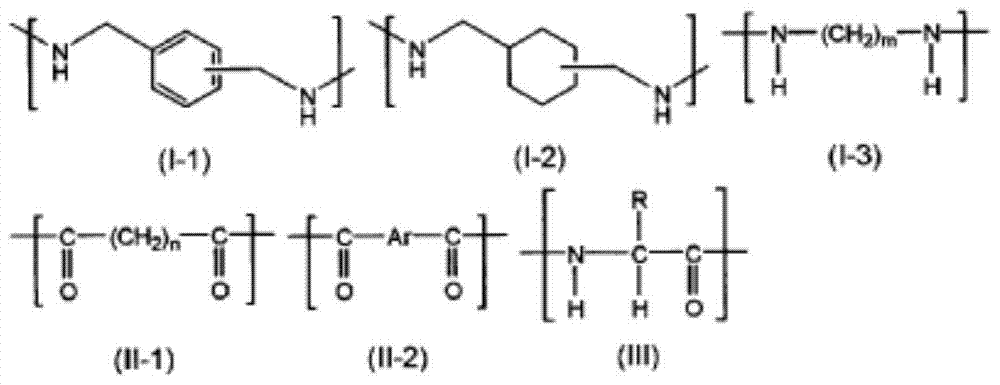

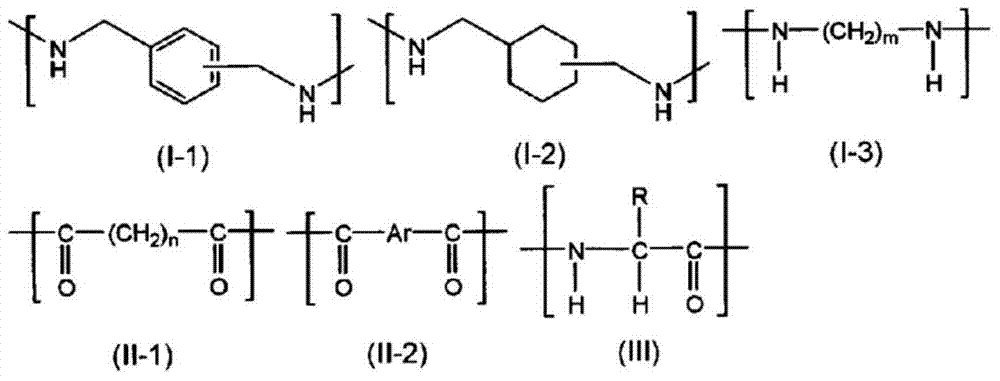

Polyamide resin composition and method for producing same

A polyamide resin, manufacturing method technology, applied in chemical instruments and methods, synthetic resin layered products, types of packaging items, etc., can solve the problem of damaged color tone or strength of molded bodies, unpleasant odor, inability to use metal detectors, etc. problem, to achieve the effect of improving the appearance design, excellent oxygen absorption performance, and excellent oxygen absorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0255] Hereinafter, although an Example demonstrates this invention in more detail, this invention is not limited to these Examples.

[0256] It should be noted that, in the following examples, regarding the units constituting the copolymer,

[0257] The units derived from m-xylylenediamine are referred to as "MXDA",

[0258] The unit derived from adipic acid is referred to as "AA",

[0259] The unit derived from isophthalic acid is referred to as "IPA",

[0260] The unit derived from L-alanine is called "L-Ala".

[0261] In addition, poly-m-xylylene adipamide is referred to as "N-MXD6".

[0262] The α-amino acid content, relative viscosity, terminal amino group concentration, glass transition temperature, and melting point of the polyamide resins obtained in Production Examples were measured by the following methods. In addition, a film was produced from the polyamide resin obtained in the production example, and the oxygen absorption amount thereof was measured by the fo...

manufacture example 1

[0275] Production example 1 (production of polyamide resin 1)

[0276]In a pressure-resistant reaction vessel with an internal volume of 50L equipped with a mixer, a partial condenser, a total condenser, a pressure regulator, a thermometer, a drip tank and a pump, an aspirator, a nitrogen inlet pipe, a bottom discharge valve, and a strand mold , Add 13000g (88.96mol) of adipic acid (manufactured by Asahi Kasei Chemical Co., Ltd.), 880.56g (9.88mol) of L-alanine (Sinogel amino acid co.ltd), 11.7g (0.11 mol), 6.06 g (0.074 mol) of sodium acetate, and after sufficient nitrogen substitution, the inside of the reaction vessel was sealed, and the temperature was raised to 170° C. under stirring while keeping the inside of the vessel at 0.4 MPa. After reaching 170° C., 12082.2 g (88.71 mol) of m-xylylenediamine (manufactured by Mitsubishi Gas Chemical Co., Ltd.) stored in a dropping tank was started to be added dropwise to the molten raw material in the reaction container, and the co...

manufacture example 2

[0277] Production example 2 (production of polyamide resin 2)

[0278] Except that the feeding composition ratio of each monomer is set as m-xylylenediamine: adipic acid: L-alanine=44.4:44.5:11.1 (mol%), operate in the same manner as in Manufacturing Example 1, thereby obtaining MXDA / AA / L-Ala copolymer (polyamide resin 2).

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com