Preparation method of bismuth oxyhalide/bismuth oxide visible-light photocatalyst

A photocatalyst and bismuth oxyhalide technology, which is applied in the field of visible light photocatalyst preparation, can solve the problems of high photo-generated carrier recombination rate, low catalytic efficiency, reduced photo-generated carrier recombination rate, etc. Simplicity and the effect of reducing the recombination rate of photogenerated carriers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) Weigh a certain amount of Bi(NO 3 ) 3 ·5H 2 O is put into the polytetrafluoroethylene liner liner that fills 75ml ethylene glycol, puts in a certain amount of KCl after stirring for 0.5h with a magnetic stirrer, moves in the autoclave after stirring again for 0.5h, is placed in the oven, set After reacting at a fixed temperature for a period of time, cool naturally to room temperature, collect the product by suction filtration, wash alternately with deionized water and absolute ethanol three times, and dry in an oven at 100°C for 2 hours to obtain the off-white product BiOCl.

[0028] (2) Weigh Bi(NO 3 ) 3 ·5H 2 O and KBr, Bi(NO 3 ) 3 ·5H 2O is put into the polytetrafluoroethylene reaction liner that fills 75ml ethylene glycol, after stirring for 0.5h with a magnetic stirrer, KBr is added, and then moved into a high-temperature reactor after stirring for 0.5h, placed in an oven, at a set temperature Heated at constant temperature for a certain period of time...

Embodiment 2

[0033] (1) Dissolve 10mmol bismuth nitrate in 40mL, 4mol / L nitric acid solution, stir well until dissolved, adjust the pH to 7 with 100mL, 1.9mol / L sodium hydroxide solution, stir magnetically at room temperature for 1.2 hours, filter, Washed three times with absolute ethanol and distilled water, dried the product at 50°C for 10 hours, and then calcined at 300°C for 10 hours to obtain yellow bismuth oxide.

[0034] (2) Add 0.0143mL of 37% hydrochloric acid to 0.4g of the prepared bismuth oxide, the molar ratio of hydrochloric acid to bismuth oxide is 0.1:1, ultrasonic reaction for 0.5 hours, and then centrifuged for 1 hour (rotation speed is 4000r / min), and then dried at a constant temperature of 50 °C for 10 hours to prepare a bismuth oxychloride / bismuth oxide photocatalyst, marked as (0.1BiOCl / Bi 2 o 3 ).

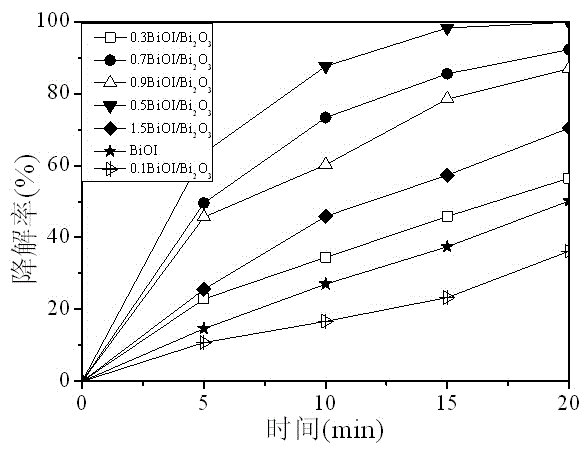

[0035] Composite photocatalyst 0.1BiOCl / Bi prepared by taking the degradation of rhodamine B as a model reaction 2 o 3 Photocatalytic activity: 0.05g catalyst 0.1BiO...

Embodiment 3

[0037] (1) Dissolve 10mmol bismuth nitrate in 40mL, 4mol / L nitric acid solution, stir well until dissolved, adjust the pH to 7 with 100mL, 1.9mol / L sodium hydroxide solution, stir magnetically at room temperature for 2 hours, filter, Wash with absolute ethanol and distilled water for 5 times, dry the product at 100°C for 7 hours, and then calcinate at 600°C for 3 hours to obtain yellow bismuth oxide.

[0038] (2) Add 0.043mL of 37% hydrochloric acid to 0.4g of prepared bismuth oxide, the molar ratio of hydrochloric acid to bismuth oxide is 0.3:1, ultrasonic reaction for 2 hours, then centrifuged for 2 hours (4000r / min), and then dried at a constant temperature of 100 °C for 4 hours to prepare a bismuth oxychloride / bismuth oxide photocatalyst, marked as (0.3BiOCl / Bi 2 o 3 ), the scanning electron microscope image is shown in Figure 4 (b), with Figure 4 (a) Comparison will find that Bi 2 o 3 surface will become rough.

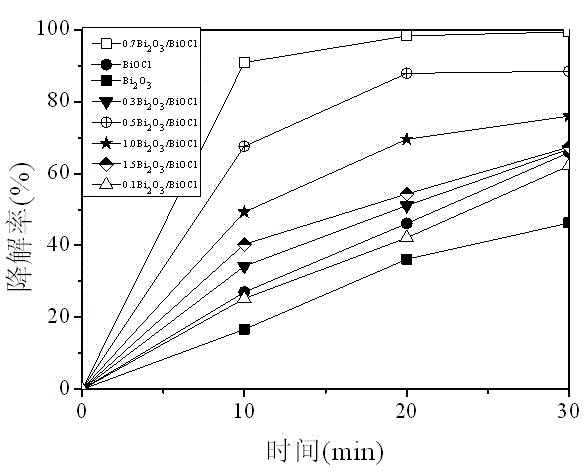

[0039] Composite photocatalyst 0.3BiOCl / Bi prepare...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com