Dry-mixed elastic rough mortar and manufacturing method thereof

An elastic and sandy technology, which is applied in the field of new building decoration materials, can solve the problems of low bond strength, difficult product preservation, poor weather resistance, etc., and achieve good water immersion strength, strong tensile resistance, and temperature range. wide effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

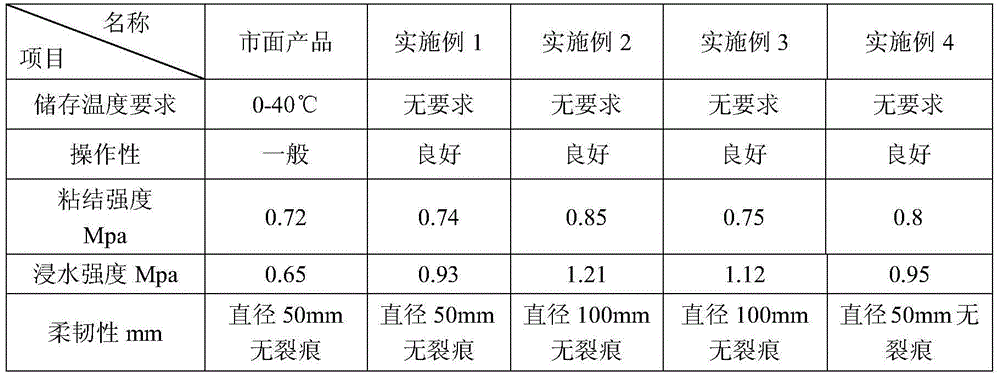

Examples

Embodiment 1

[0021] A kind of dry powder elastic brushed mortar, by mass percentage, its raw material formula is as follows:

[0022] 42.5 strength white cement 5%, 100 mesh natural stone powder 72%, polyacrylic acid redispersible latex powder 20%, attapulgite 2%, hydroxypropyl methylcellulose ether with a viscosity of 150,000 mPa.s 0.5% , 0.3% stearate water repellent, 0.2% silicone defoamer.

[0023] The above materials are put into the screw horizontal dry powder mortar mixer according to the mass percentage and stirred for 15 minutes to obtain the dry powder elastic brushed mortar.

Embodiment 2

[0025] A kind of dry powder elastic brushed mortar, by mass percentage, its raw material formula is as follows:

[0026] 5% of 32.5R strength white cement, 2% of 150 mesh lime, 20% of polyethylene / vinyl acetate latex powder, 71.59% of 300 mesh natural stone powder, 0.3% of bentonite, hydroxypropylmethyl with a viscosity of 20,000 mPa.s 0.2% cellulose ether, 0.3% 300μm wood fiber, 0.2% silicone water repellent, 0.1% dry powder wetting agent with a water content of 0.3wt%, 0.01% citric acid retarder, and 0.3% polyether defoamer.

[0027] The above-mentioned materials are put into a screw horizontal dry powder mortar mixer according to the mass percentage and stirred for 5 minutes to obtain a dry powder elastic brushed mortar.

Embodiment 3

[0029] A kind of dry powder elastic brushed mortar, by mass percentage, its raw material formula is as follows:

[0030] 52.5 strength gray cement 30%, 450 mesh lime 5%, polyacrylic acid redispersible latex powder 11.9%, 200 mesh natural stone powder 50%, attapulgite 2%, methyl hydroxyethyl ether with a viscosity of 150,000 mPa.s 0.5% base cellulose ether, 0.2% 600μm wood fiber, 0.2% dry powder wetting agent with a water content of 0.4wt%, and 0.2% organosilicon defoamer.

[0031] The above materials are put into a screw vertical mortar mixer according to the mass percentage and stirred for 15 minutes to obtain a dry powder elastic roughened mortar.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com