Propionibacterium acnes linoleate isomerase and application thereof

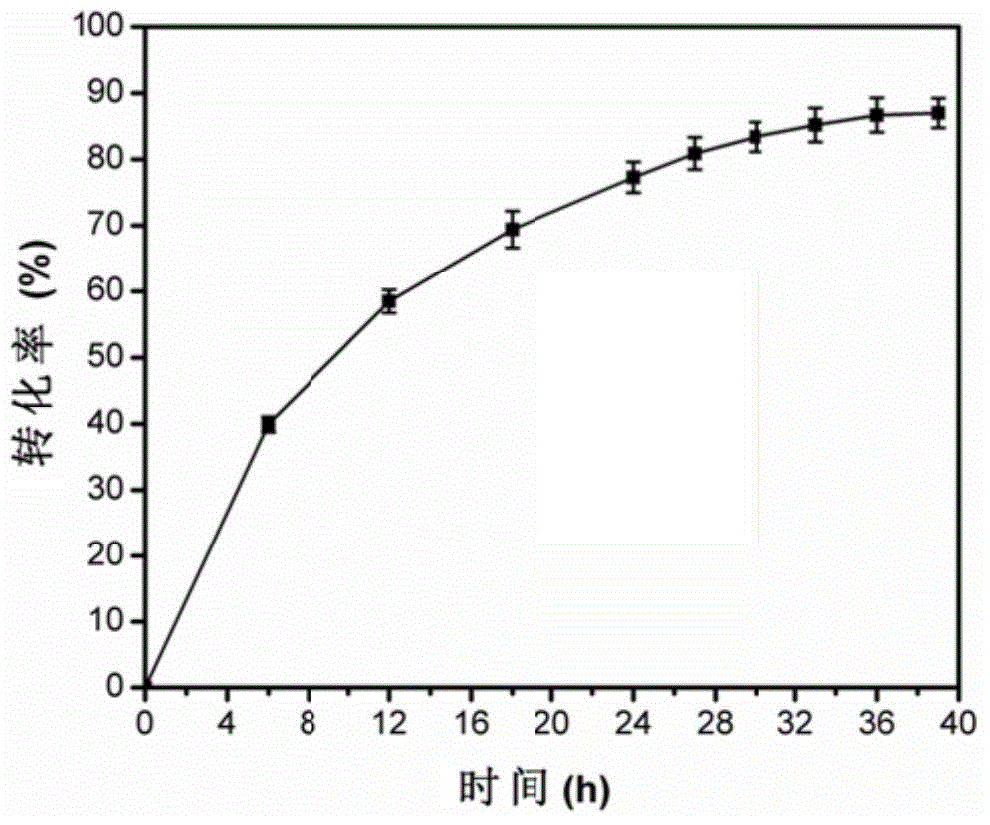

A technology of linoleic acid isomerase and Propionibacterium acnes, which is applied in the field of biological enzymatic preparation of conjugated linoleic acid, can solve problems such as unfavorable conversion production, high price, etc., achieve good economic benefits, save costs, and improve enzyme live effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1: Design and synthesis of PAI gene:

[0026] According to the codon usage frequency database information Codon Usage Database, the gene PAI encoding linoleic acid conjugating enzyme was optimized according to the preferred codons of Escherichia coli. Under the premise of not changing the amino acid sequence, the JCat codon optimization software was used to select the optimal codon, and at the same time, fine-tuning was performed with reference to the secondary structure of the mRNA to make the activation energy as high as possible, so that the mRNA was easier to express. The codon-optimized pai gene was synthesized by Shanghai Jierui Bioengineering Co., Ltd.

Embodiment 2

[0027] Embodiment 2: Cloning of recombinant PAI:

[0028] Primer: Upstream primer P1: 5'-cgccatatgtctatctccaaagacagccg-3' (with Nde I restriction site) downstream primer P2: 5'-ccg ctcgag aacgaagaagcgggtaacc-3' (incl. Xhol I restriction site).

[0029] PCR reaction system: 1 μL synthetic sequence, 1 μL upstream primer P1, 1 μL downstream primer P2, 25 μL Premix ExTaq, 22 μL ddH 2 O.

[0030] PCR reaction conditions: denaturation at 94°C for 10 min; denaturation at 94°C for 30 sec, annealing at 55°C for 30 sec, extension at 72°C for 1.5 min, 30 cycles; extension at 72°C for 10 min; incubation at 4°C.

[0031] The yield and specificity of the PCR products were detected by 1% agarose gel electrophoresis, and purified with a PCR product recovery kit (BIOMIGA, Shanghai).

[0032] Purified PCR amplification products were Nde I. Xhol After I double enzyme digestion, it was connected with the same double enzyme digestion expression plasmid pET-20b, and transformed into ...

Embodiment 3

[0033] Example 3: Induced expression and purification of recombinant PAI:

[0034]The identified positive recombinant plasmid pET-20b-pai was transformed into Escherichia coli BL21 (DE3) competent cells, and positive clones were screened on LLB plates containing Amp antibiotics (100 μg / mL). Transfer the positive clones to fresh 5 mL LLB liquid medium and culture to OD at 37°C and 180 rpm 600 At 0.6~0.8, add IPTG with a final concentration of 0.5 mmol / L, induce culture overnight at 25°C and 120 rpm. Centrifuge the induced bacterial solution at 4°C, 8000 rpm for 5 min, wash the cells twice with 20 mmol / L Tris-HCl buffer (pH 8.0), and finally resuspend the bacterial cells with 6 mL of this buffer and place in an ice bath The bacterial cells were disrupted by medium ultrasonic wave, centrifuged at 12000 rpm for 20 min at 4°C to obtain the supernatant crude enzyme solution. The supernatant crude enzyme solution was passed through the affinity Ni by the AKTA protein purifier 2+ ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com