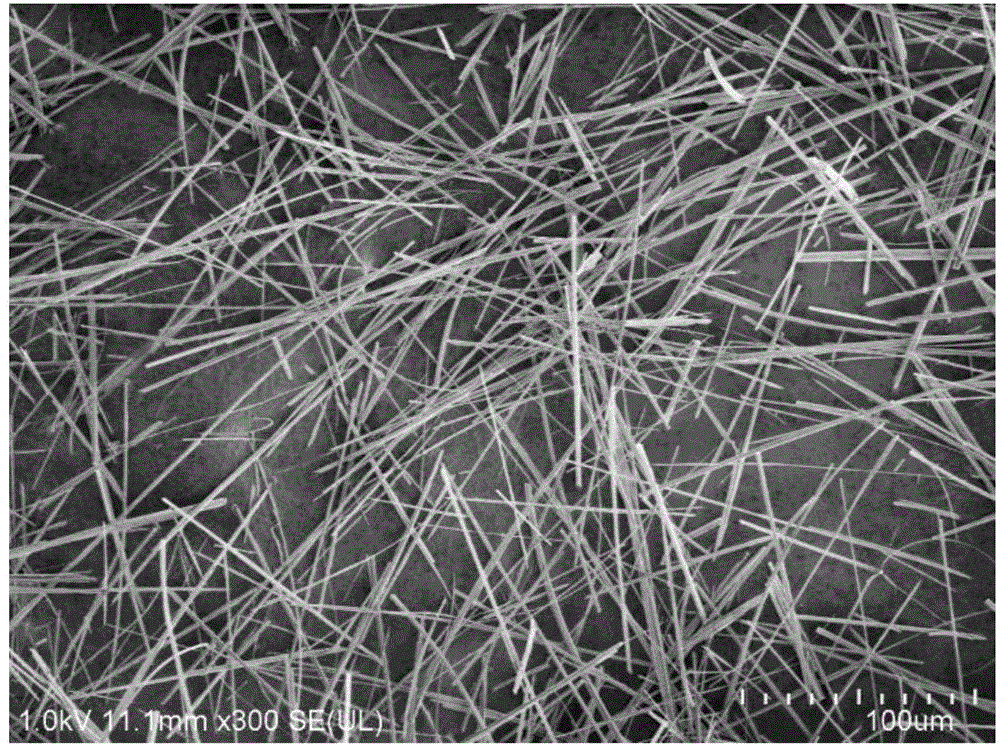

Method for preparing calcium sulfate whisker from low-grade natural gypsum or gypsum tailings

A calcium sulfate whisker and natural gypsum technology, applied in the field of calcium sulfate whisker preparation, can solve the problems of insufficient utilization of raw materials, poor quality of calcium sulfate whiskers, high requirements for raw materials, etc., achieve strong promotion and application value, reduce The effect of high production cost and aspect ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Crush the gypsum tailings, sieve through a 120-mesh sieve, add 15.00g of crushed gypsum and 300mL of 1.50mol / L hydrochloric acid solution prepared in advance to a 500mL beaker at the same time, and immerse the solution in the above beaker at a constant temperature of 80°C In a water bath, keep the temperature constant and stir for 5 hours. After the reaction is completed, suction filter while it is hot, and remove the solid residue not dissolved in the hydrochloric acid solution. After the crystallization is completed, filter with suction, wash the filter cake with acid, then wash it with water, and then dry the filter cake in an oven at 50°C for 6 hours to obtain 6.89g of high-purity gypsum product. Weigh 6.18g of high-purity gypsum product after purification, add 200mL of deionized water, add crystal growth agent magnesium chloride hexahydrate according to the mass fraction of magnesium chloride 0.04% to make slurry, transfer the slurry into the reactor, and control th...

Embodiment 2

[0037]Crush the low-grade gypsum ore, sieve it through a 120-mesh sieve, add 30.12g of the crushed gypsum and 600mL of 0.5mol / L nitric acid solution prepared in advance to a 1000mL beaker at the same time, and immerse the solution in the above beaker at 50°C In a constant temperature water bath, keep the temperature constant and stir for 10 hours. After the reaction is completed, suction filter while it is hot, and remove the solid residue not dissolved in the nitric acid solution. After the crystallization is completed, filter with suction, wash the filter cake with acid, then wash it with water, and then dry the filter cake in an oven at 40°C for 12 hours to obtain 14.28g of high-purity gypsum product. Weigh 10.53g of the purified high-purity gypsum product, add 200mL of deionized water, add crystal growth agent magnesium chloride according to the mass fraction of the solution at 0.2% to make a slurry, transfer the slurry into the reactor, and control the reaction temperature...

Embodiment 3

[0039] Crush the gypsum tailings, sieve through a 120-mesh sieve, add 60.00 g of the crushed gypsum and 900 mL of a 1.0 mol / L mixed solution of hydrochloric acid and nitric acid to a 1000 mL beaker at the same time, and immerse the solution in the above beaker in In a constant temperature water bath at 60°C, keep the temperature constant and stir for 2 hours. After the reaction is completed, suction filter while it is hot, and remove the solid residues that are not dissolved in the hydrochloric acid and nitric acid solutions. 18h. After the crystallization is complete, filter with suction, wash the filter cake with acid, then wash it with water, and then dry the filter cake in an oven at 60°C for 2 hours to obtain 35.19g of high-purity gypsum product. Weigh 26.16g of the purified high-purity gypsum product, add 200mL of deionized water, add the crystal growth agent magnesium nitrate according to the mass fraction of magnesium nitrate 0.16% to make slurry, transfer the slurry i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com