SiC MOS capacitor of Al2O3/HfxLa1-xO/SiO2 stacking gate dielectric layer and manufacturing method

A gate dielectric layer and stacking technology, which is used in semiconductor/solid-state device manufacturing, circuits, electrical components, etc., can solve the problem that the thickness of SiO2 cannot be grown too thick, the interface state density between the dielectric and the SiC substrate is high, and the oxide layer is trapped. The problems of high density and leakage current can increase the critical breakdown electric field, increase the channel mobility, and reduce the interface state density and boundary trap density.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

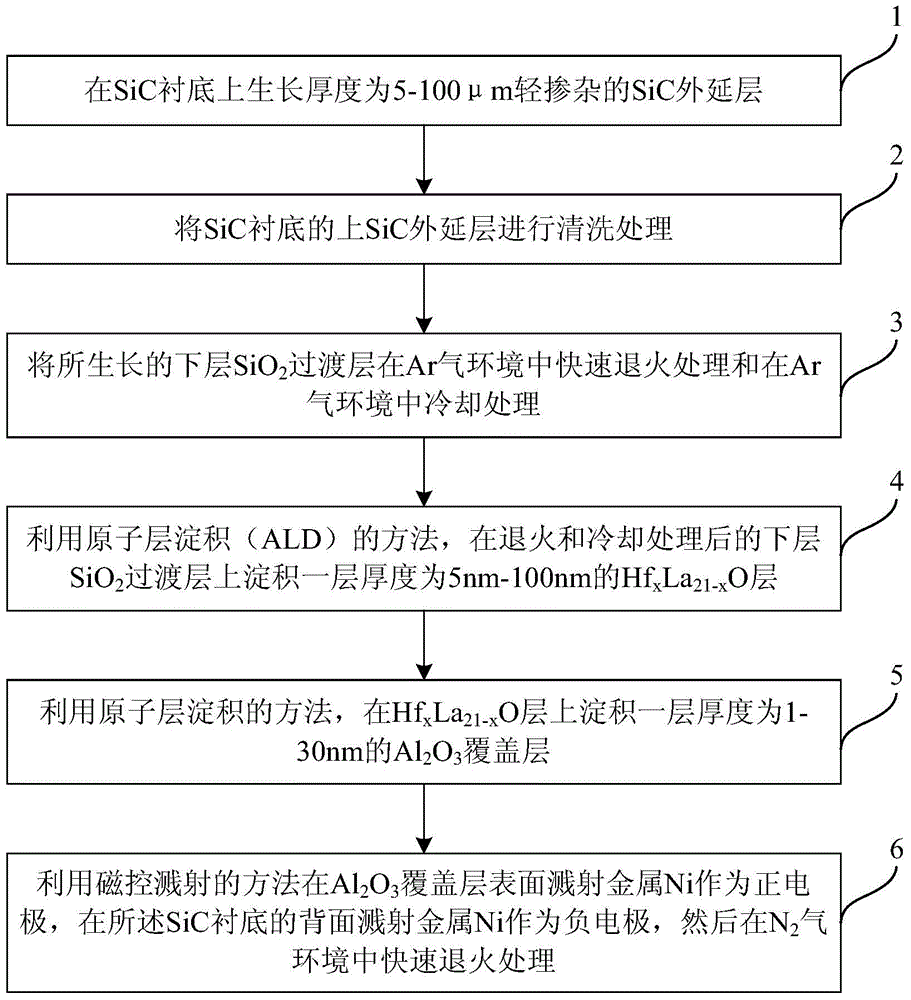

[0033] The technical solutions of the present invention will be described in further detail below with reference to the accompanying drawings and embodiments.

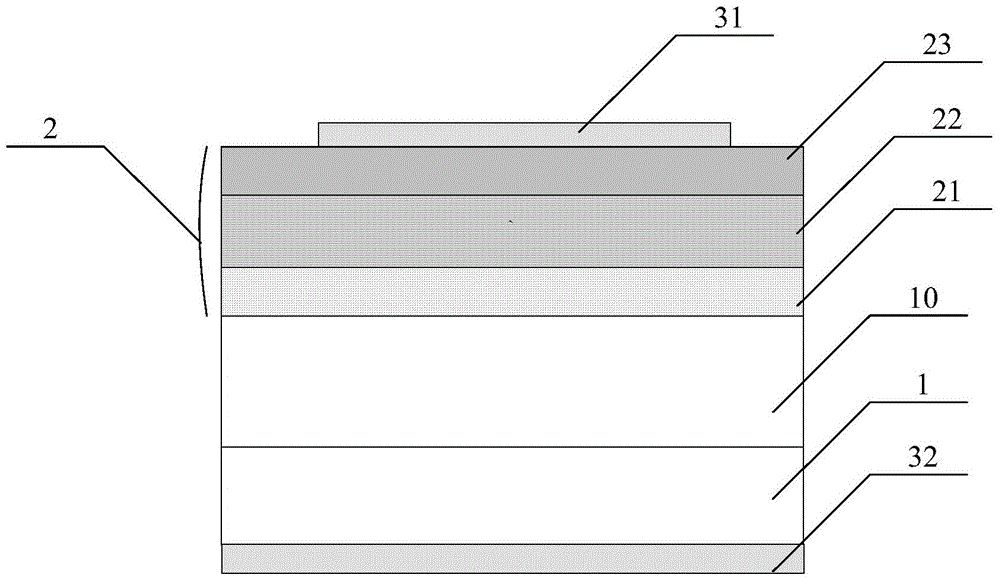

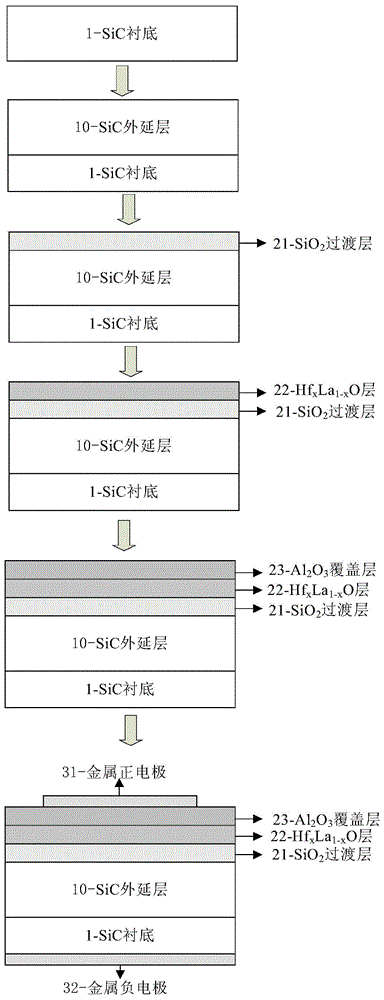

[0034] figure 1 For the present invention Al 2 o 3 / Hf x La 1-x O / SiO 2 A schematic diagram of a SiC MOS capacitor with stacked gate dielectric layers, as shown in the figure, the present invention includes: SiC substrate 1 , SiC epitaxial layer 10 , stacked gate dielectric layer 2 and positive and negative electrodes 3 .

[0035] SiC epitaxial layer 10 is provided on SiC substrate 1;

[0036] The stacked gate dielectric layer 2 includes the lower SiO 2 Transition layer 21, Hf x La 1-x O layer 22 and Al 2 o 3 Covering layer 23; SiC epitaxial layer 10 is provided with lower layer SiO 2 Transition layer 21, lower layer SiO 2 The transition layer 21 is provided with Hf x La 1-x O layer 22, Hf x La 1-x O layer 22 is provided with Al 2 o 3 Overlay 23;

[0037] Positive electrode 31, negative electrode 32 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com