Composite carrier, pH response type compound drug-loading system and preparation method of composite carrier

A composite carrier and drug-carrying technology, which is applied in the direction of pharmaceutical formulations, medical preparations of non-active ingredients, etc., to achieve the effect of uniform size and good dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0121] The preparation method of composite carrier of the present invention comprises the following steps:

[0122] (a) 3-glycidyl ether trimethoxysilane is connected to the molecular chain of the carboxymethyl chitosan to obtain a compound;

[0123] (b) The composite obtained in step a) reacts with mesoporous silica, and the carboxymethyl chitosan is grafted to the surface of the mesoporous silica through 3-glycidyl ether trimethoxysilane to obtain The composite carrier.

[0124] When preparing the composite drug-loading system of the present invention, the macromolecular protein drug is loaded on the mesoporous silica, and then reacts with the complex obtained in step a) to obtain a composite drug-loading system.

[0125] In a preferred embodiment, the preparation method comprises the steps of:

[0126] (i) carboxymethyl chitosan molecule is dispersed in water, and its surface is modified with 3-glycidyl ether trimethoxysilane;

[0127] (ii) The surface-modified carboxyme...

Embodiment 1

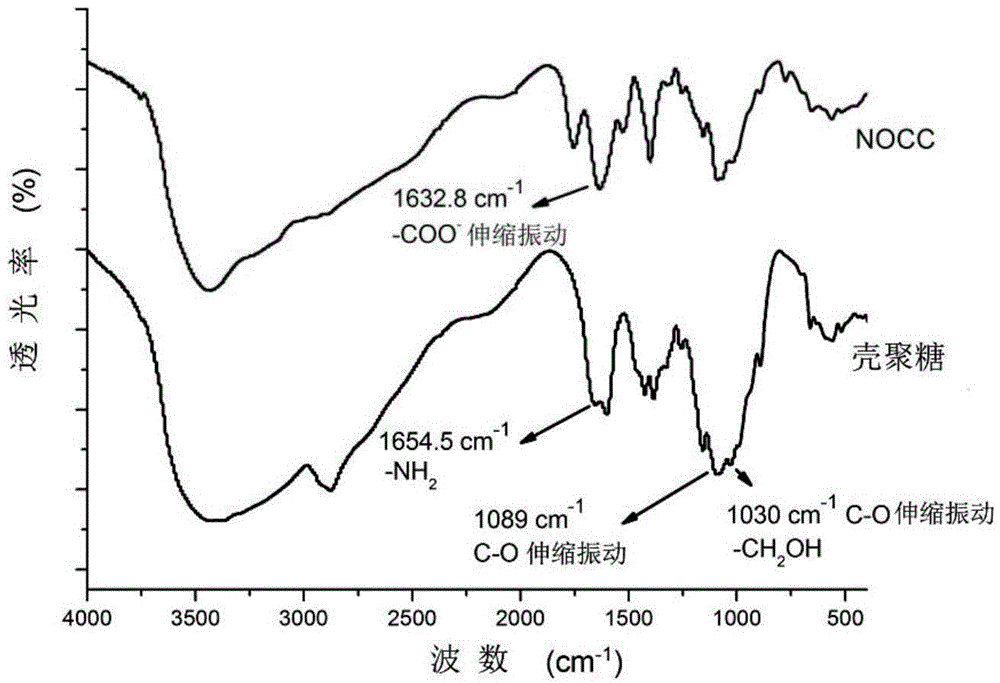

[0164] Synthesis of N,O-Carboxymethyl Chitosan (NOCC)

[0165] Weigh 10g chitosan (molecular weight 3×10 5 g / mol, degree of deacetylation 90%) powder, under stirring at room temperature, join in the 500ml three-necked flask that fills 100ml isopropanol, then 25ml concentration is that the NaOH of 10mol / L is divided into 5 parts equally, within 25min respectively Add it to the flask, and continue to stir for 30 minutes after the addition is complete.

[0166] After the stirring finishes, weigh 60g of monochloroacetic acid, divide it into 5 parts, and add a part to the flask every one minute.

[0167] After the addition, the temperature of the system was raised to 60° C., and the reaction was continued for 3 h.

[0168] The reaction was terminated, the obtained product was filtered, and the filtrate was washed with anhydrous methanol, and dried in vacuum at 60° C. to obtain a yellow solid (molecular weight 3×10 5 g / mol, degree of deacetylation 90%). Hereinafter marked as NOC...

Embodiment 2

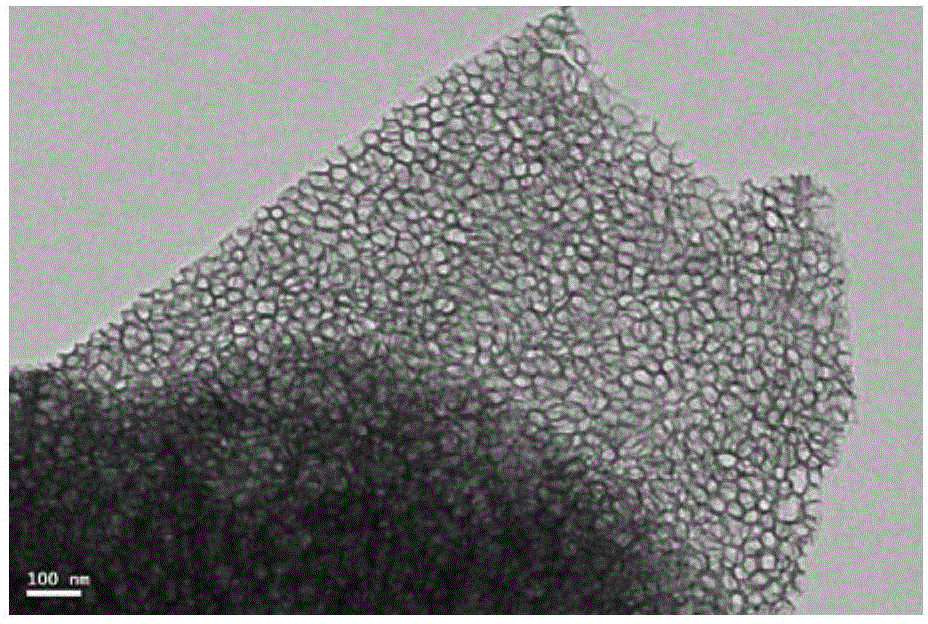

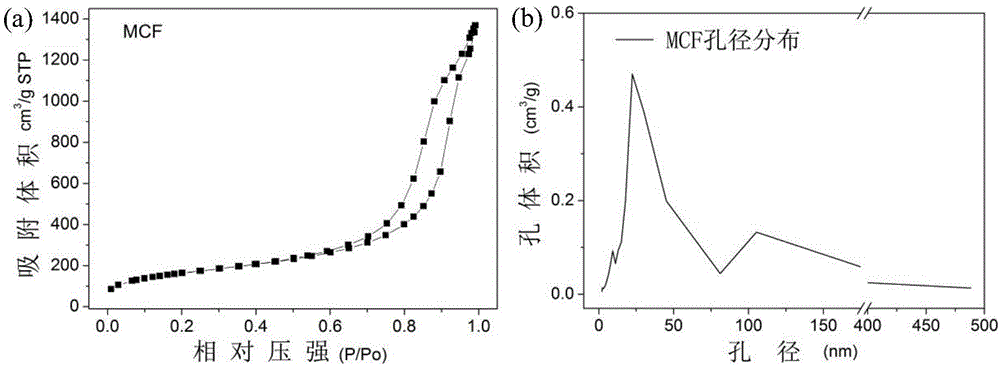

[0172] Preparation of Large Mesoporous Silica Nanoparticles 1-MCF by Sol-Gel Method

[0173] Add 10ml of concentrated hydrochloric acid with a mass fraction of 37% and 65ml of ultrapure water into the reaction vessel, mix well, and keep in a 40°C water bath.

[0174] Then, 4 g of polyethylene oxide-polypropylene oxide-polyethylene oxide triblock copolymer (P123) was slowly added to the mixture and stirred vigorously for about 1 h until it was completely dissolved, and the solution was in a clear state.

[0175] After the dissolution was complete, 4 g of trimethylolpropane (TMP) was added to the mixture, and kept stirring in a water bath at 40° C. for 2 h. Afterwards, 9.2 ml of tetraethyl orthosilicate (TEOS) was added dropwise and stirred vigorously, and the stirring was continued for 5 minutes after the addition was completed.

[0176] The addition of the first stage was completed, and the system was aged in a water bath at 40° C. for 20 h. Then add 46mg NH 4 F, stir gentl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com