Synthesis of novel compound photocatalyst Bi2S3/BiOCl as well as application of photocatalyst

A composite catalyst and catalyst technology, applied in the field of photocatalysis, can solve the problems of high cost, unfriendly environment, and unsatisfactory results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0084] 7.0g of Bi(NO 3 ) 3 ·5H 2 O and 0.27g thiourea were placed in 20 ml of 0.10mol / LHNO 3 solution, the above mixture was stirred and subjected to ultrasonic treatment,

[0085] Use a certain concentration of sodium hydroxide solution to adjust the pH of the solution to 7.0, then add 0.15g KCl and 30mL ethylene glycol;

[0086] Transfer the mixture to a polytetrafluoroethylene-lined stainless steel autoclave at 433K (about 160°C) for 24h;

[0087] Cool to room temperature, centrifuge to obtain the product, wash with absolute ethanol and deionized water, and dry at 373K (about 100°C) to obtain a composite photocatalyst sample.

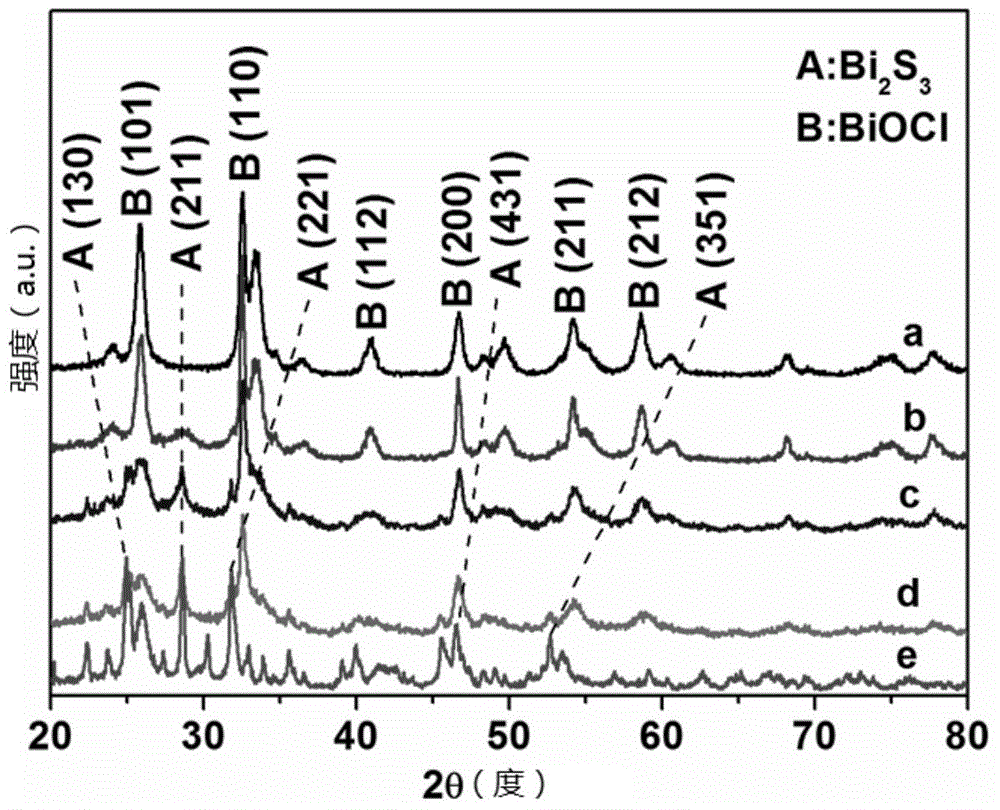

[0088] Bi in the prepared sample 2 S 3 The weight fraction is 13.3%, and its XRD spectrum is as figure 1 Shown in the curve marked b.

Embodiment 2

[0090] The present embodiment is the same as the method used in embodiment 1, the difference is only that in step 1 Bi(NO 3 ) 3 ·5H 2 The weight of O is 3.5 g. Bi in the prepared sample 2 S 3 The weight fraction is 26.5%, and its XRD spectrum is as figure 1 Shown in the curve marked c.

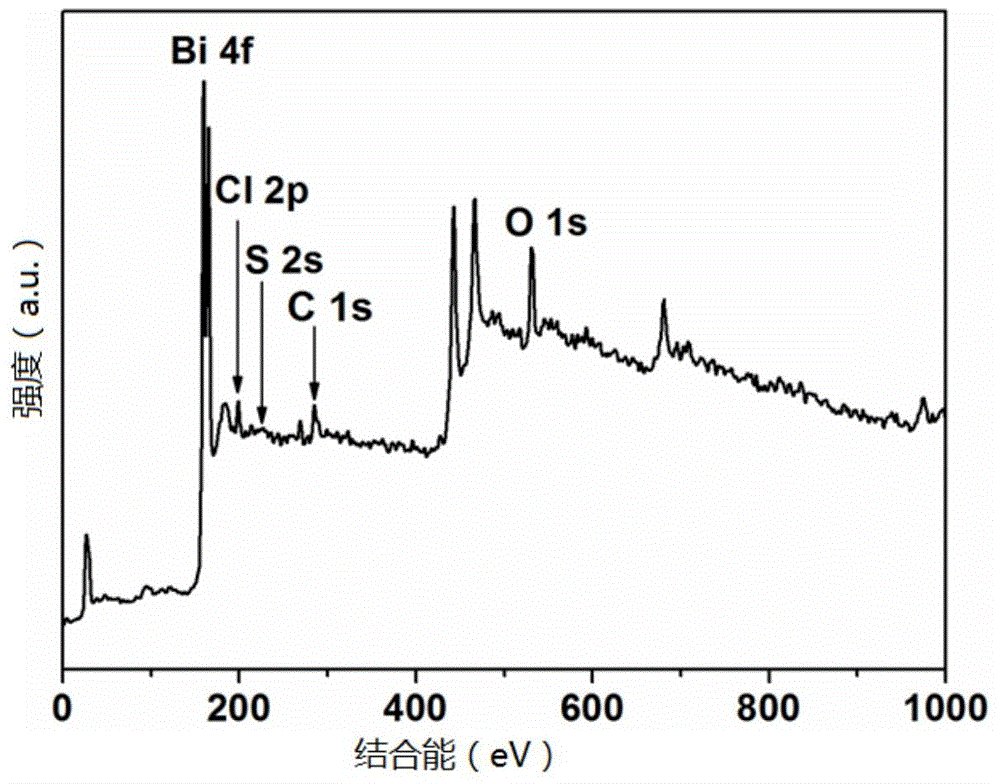

[0091] Its X-ray photoelectron spectroscopy Figure 3a ~ Figure 3d as shown,

[0092] Depend on Figure 3a It can be seen that there are Bi 4f peaks, Cl 2p peaks, S 2s peaks, and O1s peaks in the spectrum, that is, the sample contains Bi, Cl, S, and O elements (the C 1s peak is caused by the hydrocarbons brought by the measuring instrument itself. the peak);

[0093] Depend on Figure 3b It can be seen that the excitation energies of the two peaks of Bi 4f in the sample are 164.5eV and 159.2eV respectively;

[0094] Depend on Figure 3c It can be seen that the excitation energies of the two peaks of Cl 2p in the sample are 198.0eV and 199.4eV respectively;

[0095] Depend on Fig...

Embodiment 3

[0098] This embodiment is the same as the method used in embodiment 1, the difference is only that in step 1 the Bi(NO 3 ) 3 ·5H 2 Bi in the sample was prepared after the weight of O 2 S 3 The weight fraction is 39.8%, and its XRD spectrum is as figure 1 Shown in the curve marked d.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com