Process for cleaning and regenerating denitration catalyst

A denitration catalyst and process technology, applied in catalyst regeneration/reactivation, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the reduction of denitration catalyst active components, catalyst wear resistance, and denitration efficiency. problem, to increase the activity and thermal stability, prevent the catalyst from arsenic poisoning, and avoid the effects of multiple roasting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

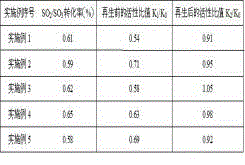

Embodiment 1

[0012] For inactivated but still mechanical life and SO 2 / SO 3 For the denitrification catalyst with a conversion rate of 0.61%, take the following steps to regenerate: 1. Preparation of cleaning solution and regeneration solution: (1) Preparation of cleaning solution: prepare 0.1mol / L sulfuric acid solution; Fractions are 0.05% ferrous sulfate; 1% manganese sulfate; 0.08% cerium nitrate; 0.10% lanthanum nitrate; 0.05% S-185. (2) Preparation of regeneration solution: first mix 0.5% vanadyl oxalate and 98.75% deionized water evenly, then add 0.3% ammonium metatungstate and 0.05% ammonium molybdate and stir until completely dissolved , and finally put in 0.4% mass fraction of silica sol ST-O and continue stirring until homogeneous. 2. Regeneration method of denitrification catalyst: After the deactivated but still mechanically durable denitrification catalyst module is purged sequentially, soak in the denitrification catalyst cleaning solution prepared in step (1) for 10 minu...

Embodiment 2

[0014] For inactivated but still mechanical life and SO 2 / SO 3 For the denitrification catalyst with a conversion rate of 0.59%, take the following steps to regenerate: 1. Preparation of cleaning solution and regeneration solution: (1) Preparation of cleaning solution: prepare 0.3mol / L sulfuric acid solution; Fractions are 1% ferrous sulfate; 2% manganese sulfate; 0.10% cerium nitrate; 0.10% lanthanum nitrate; 0.1% S-185. (2) Preparation of regeneration solution: first mix 1% vanadyl oxalate and 97.54% deionized water evenly, then add 1% ammonium metatungstate and 0.06% ammonium molybdate and stir until completely dissolved , and finally put in 0.4% mass fraction of silica sol ST-O and continue stirring until homogeneous. 2. Denitrification catalyst regeneration method: After the deactivated but still mechanically durable denitration catalyst modules are purged sequentially, soak in the denitration catalyst cleaning solution prepared in step (1) for 15 minutes, and then soa...

Embodiment 3

[0016] For inactivated but still mechanical life and SO 2 / SO 3 For the denitrification catalyst with a conversion rate of 0.62%, take the following steps to regenerate: 1. Preparation of cleaning solution and regeneration solution: 1) Preparation of cleaning solution: prepare 0.4mol / L sulfuric acid solution; under the condition of strong stirring, add the mass fraction 5% of manganese sulfate; 0.12% of cerium nitrate; 0.12% of lanthanum nitrate; 0.5% of S-185. (2) Preparation of regeneration solution: First, stir 2% vanadyl oxalate and 95.42% deionized water evenly, then add 2% ammonium metatungstate and 0.08% ammonium molybdate and stir until completely dissolved , and finally put in 0.5% mass fraction of silica sol ST-O and continue stirring until homogeneous. 2. Regeneration method of denitrification catalyst: after the deactivated but still mechanically durable denitrification catalyst module is purged sequentially, soak in the denitrification catalyst cleaning solution...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com