ZrO2 with micro/nano structure and preparation method of ZrO2

A nanostructure and nanosphere technology, applied in the fields of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., to achieve the effects of easy operation, cheap and easily available raw materials, and simple and novel methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] The present invention also discloses a kind of above-mentioned micro / nano structure ZrO 2 The preparation method comprises the following steps:

[0043] S1. The parts by weight are respectively 0.1-0.3 parts of β-cyclodextrin and 1.5-2.6 parts of ZrOCl 2 .8H 2 O, 1.9-2.2 parts of EDTA and 1.68 parts of NaHCO 3 Dissolve in 50 parts of water to obtain a mixed solution;

[0044] S2. Transfer the above-mentioned mixed solution system to a high-pressure reactor, and heat-treat at 150-220° C. for 5-30 hours;

[0045] S3. After the heat treatment, the autoclave is naturally cooled at room temperature, and then the precipitate is separated and washed with deionized water. After drying or calcination, the micro / nanostructure ZrO 2 .

[0046] In step S1, β-cyclodextrin, ZrOCl can be added to the water in sequence 2 .8H 2 O, EDTA and NaHCO 3 , to get a mixed solution after fully stirring; you can also add β-cyclodextrin and ZrOCl in water first 2 .8H 2 O, stir well befor...

Embodiment 1

[0049] The preparation method comprises the following steps:

[0050] S11. Add 0.142g of β-cyclodextrin and 1.61g of ZrOCl to 50g of water respectively 2 .8H 2 O, then add 1.68g of NaHCO 3 And the ethylenediaminetetraacetic acid of 2.0g, obtain mixed solution after stirring for 40min;

[0051] S12, transfer the above-mentioned mixed solution into the autoclave, and heat-treat under the condition of 200°C for 6 hours;

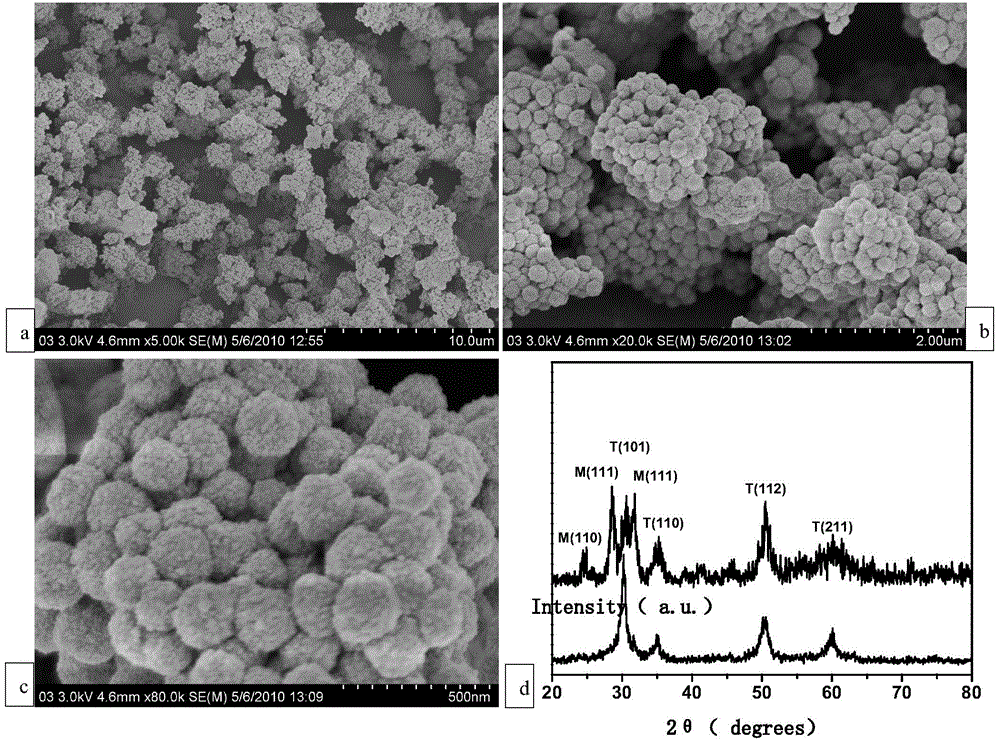

[0052] S13. Take out the autoclave and age at room temperature for 8 hours, then separate the precipitate and wash it with deionized water. After drying or calcination, the micro / nanostructure ZrO 2 , the sample is then calcined at 700°C to obtain a tetragonal and monoclinic mixed crystal phase micro / nanostructure ZrO 2 . The resulting sample was analyzed for morphology and crystal phase with a Japanese S-4800 scanning electron microscope and a German BrukerAXS D8ADVANCE X-ray diffractometer. The results are shown in figure 1 .

[0053] from figure 1 (a,...

Embodiment 2

[0055] The preparation method comprises the following steps:

[0056] S21, add 0.142g of β-cyclodextrin and 1.61g of ZrOCl in 30g of water 2 .8H 2 O, after stirring for 20min, make solution A; then add 1.68g of NaHCO in 20g of water 3 and 2.0g of EDTA, after stirring for 20min, it was made into solution B; after mixing the two solutions of A and B, they were fully stirred to obtain a mixed solution;

[0057] S22, transfer the above mixed solution into the autoclave, heat treatment at 200°C for 8 hours;

[0058] S23. Take out the autoclave and age at room temperature for 12 hours, then separate the precipitate and wash it with deionized water, dry or calcinate to obtain the micro / nanostructure ZrO 2 .

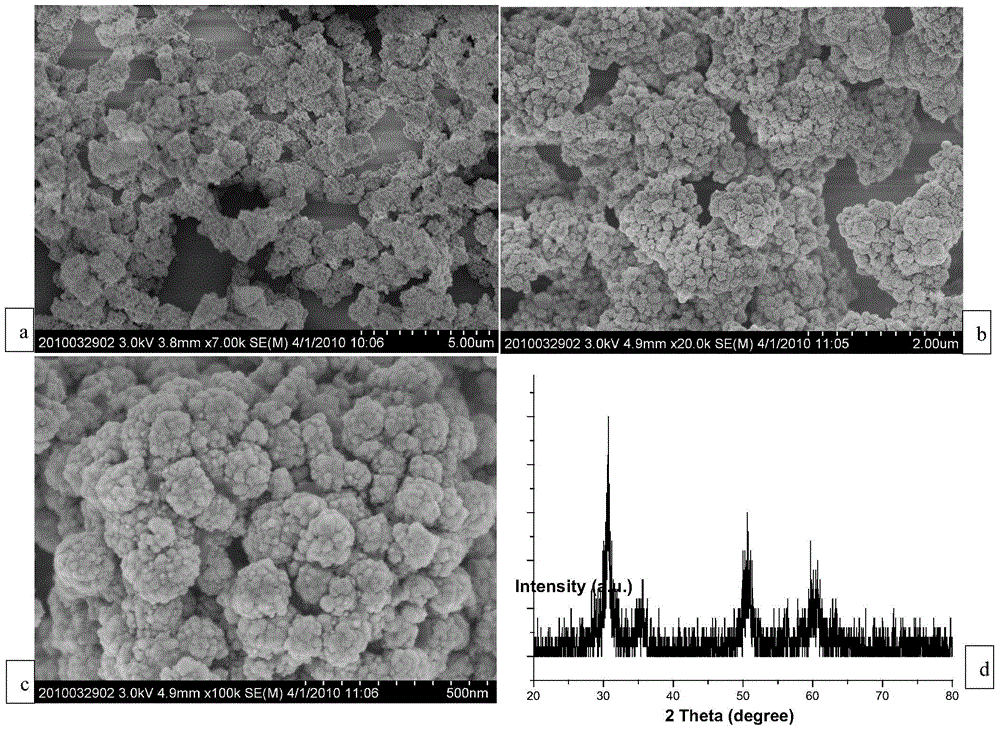

[0059] The resulting sample was analyzed for morphology and crystal phase with a Japanese S-4800 scanning electron microscope and a German BrukerAXS D8ADVANCE X-ray diffractometer. The results are shown in figure 2 .

[0060] from figure 2 (a, b, c) It can be seen that ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com