Superhydrophobic coating and preparation method thereof

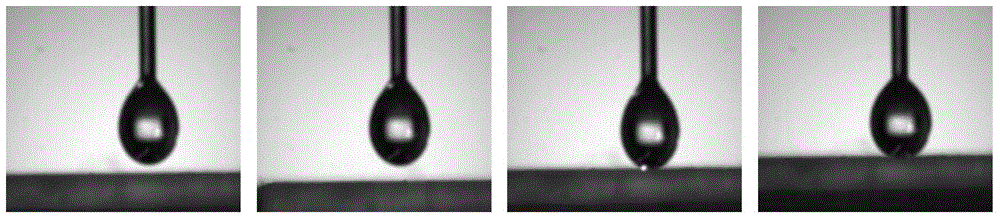

A technology of superhydrophobic coatings and glycidyl ethers, applied in polyester coatings, polyurea/polyurethane coatings, coatings, etc., can solve the problems of poor comprehensive performance of paint films, and achieve high comprehensive paint film performance, narrow molecular weight distribution, good hydrophobic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

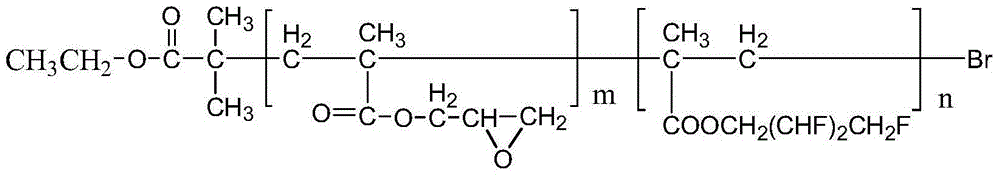

[0034] Embodiment 1: The molecular weight of fluorine-containing block copolymer is 9000, and the structure is:

[0035]

[0036] where m=56, n=6.

[0037] A. Preparation of fluorine-containing block copolymer:

[0038] Add glycidyl methacrylate (GMA) 14.22g (0.1mol), ethyl α-bromoisobutyrate (EBiB) 0.3467g (0.001778mol), CuBr 2 0.0122g (5.0×10 -5 mol), pentamethyldiethylenetriamine (PMDETA) 0.08665g (5.0×10 -4 mol), azobisisobutyronitrile (AIBN) 0.1232g (7.5×10 -4 mol), 7.11 g of toluene, after mixing uniformly, nitrogen was passed for 1 h, and reacted in an oil bath at 70° C. for 5 h. After the conversion rate reached 80%, a light yellow viscous product was obtained. Then, 1.867 g (0.0111 mol) of trifluoroethyl methacrylate (TFEMA) was added into the reaction vessel, and the reaction was continued for 5 hours to obtain a fluorine-containing block copolymer.

[0039] B. Preparation of Superhydrophobic Coatings

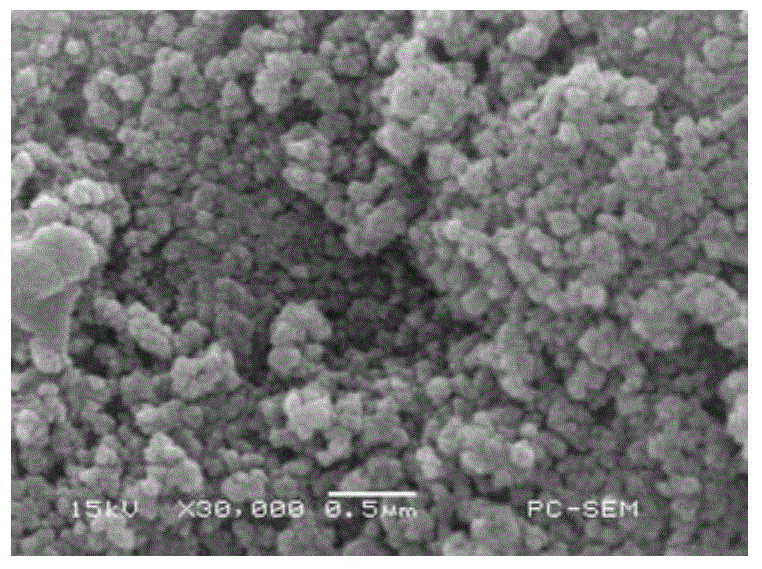

[0040] 1. Nano-TiO with amino groups on the surface 2 pr...

Embodiment 2

[0048] Embodiment 2: the molecular weight of fluorine-containing block copolymer is 12000, and the structure is:

[0049]

[0050] where m=70, n=8.

[0051] A. Preparation of fluorine-containing block copolymer:

[0052] Add GMA 14.22g (0.1mol), EBiB 0.2774g (0.001422mol), CuBr 2 0.0122g (5.0×10 -5 mol), PMDETA 0.08665g (5.0×10 -4 mol), AIBN 0.1232g (7.5×10 -4 mol), 7.11 g of toluene, after mixing uniformly, nitrogen was passed for 1 h, and reacted in an oil bath at 70° C. for 5 h. After the conversion rate reached 80%, a light yellow viscous product was obtained. Then, 2.778 g (0.0111 mol) of hexafluorobutyl methacrylate (HFBMA) was added into the reaction vessel, and the reaction was continued for 5 hours to obtain a fluorine-containing block copolymer.

[0053] B. Preparation of Superhydrophobic Coatings

[0054] 1. Preparation of nano-ZnO with amino groups on the surface

[0055] Add 0.3g KH550, 5g nano-ZnO, and 50g ethyl acetate into the reactor, stir the reacti...

Embodiment 3

[0062] Embodiment 3: the molecular weight of fluorine-containing block copolymer is 15000, and the structure is:

[0063]

[0064] where m=84, n=9.

[0065] A. Preparation of fluorine-containing block copolymer:

[0066] Add GMA 14.22g (0.1mol), EBiB 0.2311g (0.001185mol), CuBr 2 0.0122g (5.0×10 -5 mol), PMDETA 0.08665g (5.0×10 -4 mol), AIBN 0.1232g (7.5×10 -4 mol), 7.11 g of toluene, after mixing uniformly, nitrogen was passed for 1 h, and reacted in an oil bath at 70° C. for 5 h. After the conversion rate reached 80%, a light yellow viscous product was obtained. Then, 4.444 g (0.0111 mol) of dodecafluoroheptyl methacrylate (DFHMA) was added into the reaction vessel, and the reaction was continued for 5 hours to obtain a fluorine-containing block copolymer.

[0067] B. Preparation of Superhydrophobic Coatings

[0068] 1. Nano-SiO with amino groups on the surface 2 preparation of

[0069] 0.60g KH550, 10g nano-SiO 2 1. 50 g of ethyl acetate was added to the reacto...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Impact strength | aaaaa | aaaaa |

| Pencil hardness | aaaaa | aaaaa |

| Impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com