High-purity hydrogen production process and system and ammonia synthesis process and system

A production process, high-purity technology, applied in hydrogen/syngas production, gasification process, bulk chemical production, etc., can solve the problems affecting economic benefits and long-term development, rising prices of urea products, large emissions of waste gas and wastewater, etc. problems, to achieve the effect of high effective gas utilization, less catalyst dosage, and high gas purification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

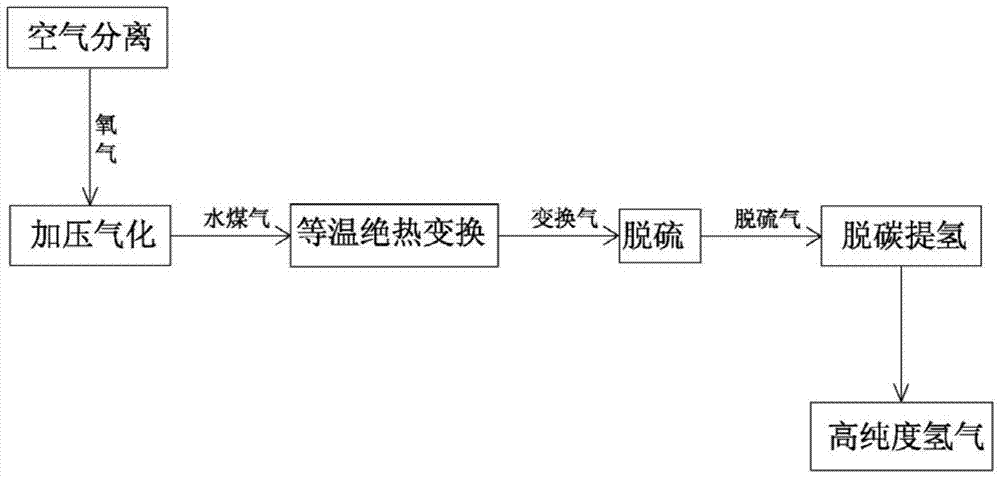

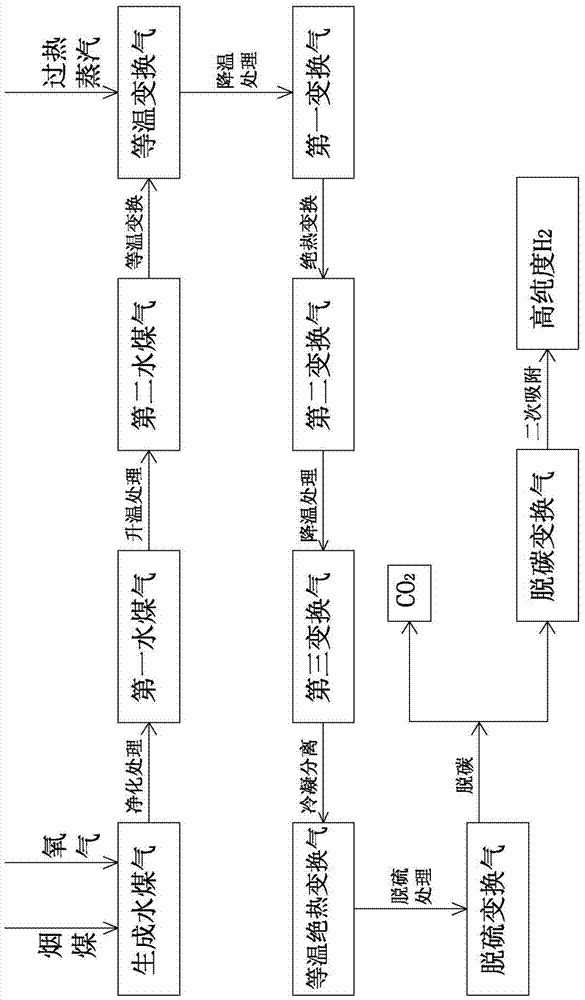

[0068] see figure 2 and image 3 , the present embodiment provides a production process of high-purity hydrogen, which uses bituminous coal as raw material, comprising the following steps:

[0069] S100: Bituminous coal generates water gas; bituminous coal and oxygen pressurized gasification produces water gas, and the CO content in the generated water gas is 65% to 75%.

[0070] In this example, bituminous coal, oxygen and water vapor are used to react to generate water gas in the gasifier, wherein the ratio of bituminous coal, oxygen and water vapor is 100:89:54, the reaction temperature is 1000-1500°C, and the gasification pressure is 0.5 to 4.0MPa. The CO content of the water gas generated by the existing anthracite gasifier is 25-40%. In the present invention, bituminous coal is used as fuel to gasify in the gasifier, so that the generated CO content reaches 65-75%. (H2+CO) reaches 90%, the temperature of the generated water gas is 160°C to 170°C, and the water conten...

Embodiment 2

[0097] Correspondingly, see Figure 4 , the present invention also provides a high-purity hydrogen production system, the system includes a water gas generation part 1, a shift gas generation part 2, a shift gas desulfurization part 3 and a shift gas decarbonization hydrogen extraction part 4, the water gas generation part 1 and Between the shift gas generation part 2, between the shift gas generation part 2 and the shift gas desulfurization part 3, and between the shift gas desulfurization part 3 and the shift gas decarbonization and hydrogen extraction part 4 are all connected by pipelines.

[0098] Preferably, as an implementable mode, the water gas generation part 1 includes a raw material delivery device 101, an air separation device 102 and a gasifier 103, the fuel enters the gasifier 103 through the raw material delivery device 101, and the oxygen separated by the air separation device 102 Entering the gasification furnace 103 , the bituminous coal and oxygen are pressu...

Embodiment 3

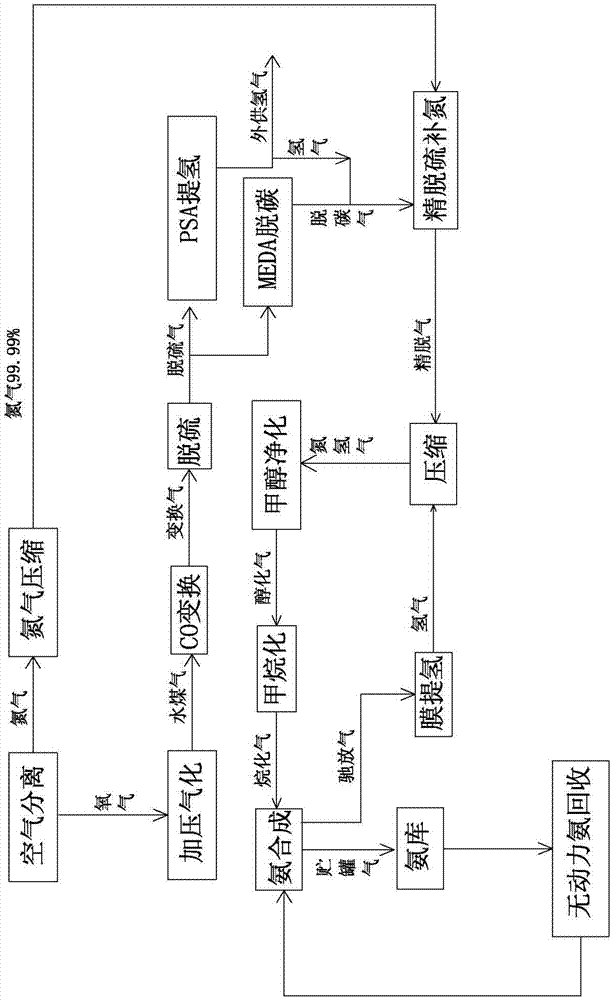

[0106] see Figure 5 and Figure 6 , the present embodiment provides a synthetic ammonia process, which uses the steps of the high-purity hydrogen production process described in Embodiment 1 to produce high-purity hydrogen, and then also includes the following steps:

[0107] Step S500: supplementing nitrogen with hydrogen to remove oxygen; mixing the high-purity H2 and nitrogen obtained in step S400 according to the ratio, and then removing trace oxygen in the mixed gas to obtain nitrogen-hydrogen mixed gas. In this step, the operating pressure is 1.2-1.4 MPa (preferably 1.3 MPa), and the operating temperature is 30-45°C (preferably 35°C).

[0108] Preferably, as an implementable manner, the nitrogen in this step is separated from the air separation device with a purity of 99.99% nitrogen, and the nitrogen needs to be compressed and then mixed with hydrogen.

[0109] The main purpose of this step is to supplement hydrogen and nitrogen into hydrogen according to the require...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com