Complex fermentation inoculum for night soil, and preparation method thereof

A technology of compound fermentation bacteria agent and fecal residue, applied in the field of starter, can solve the problems of slow heating rate of compost fermentation, ammonia gas pollution, short time for maintaining high temperature, etc., and achieve the effect of removing fecal odor and ensuring fermentation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

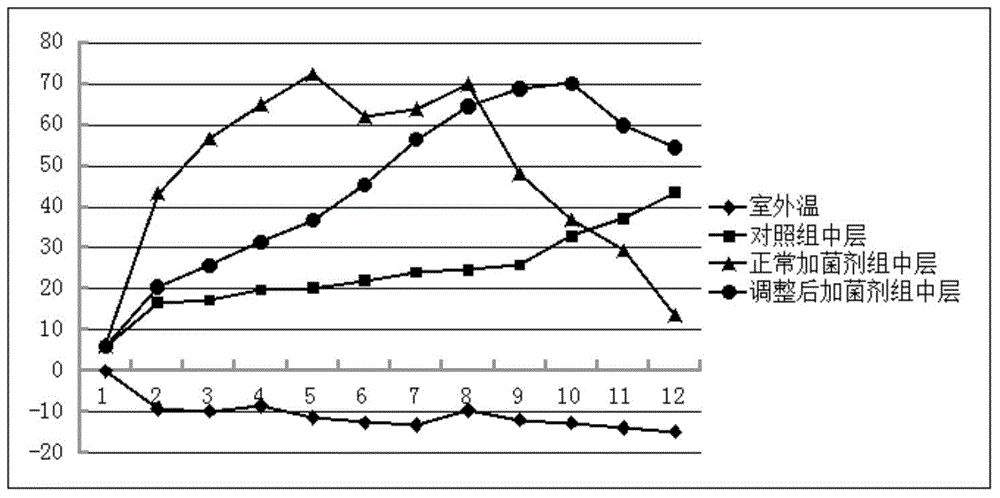

Image

Examples

Embodiment 1

[0034] The compound fermentation bacterial agent of this embodiment is made up of 30% probiotic A and 70% nutritional additive B according to the mass fraction ratio; Green non-sulfur bacteria, 15% yeast BGWW23202, 15% Lactobacillus acidophilus ACCC11073, 25% Pseudomonas ATCC31554, 10% Streptomyces ACCC40001; nutritional additive B consists of 35% corn flour by mass fraction , 20% rice husk powder, 20% sucrose, 10% dipotassium hydrogen phosphate, and 15% sodium chloride.

[0035] Note: The total number of viable bacteria per gram of each microorganism is 1~5*10 8 indivual.

[0036] Usage and dosage: ferment according to the usage ratio of 1-3‰.

[0037] Storage conditions: The bacteria content per gram of bacterial agent is not less than 10 8 , stored away from light, the shelf life is 2 years, and the decomposition temperature is 65°C-72°C.

Embodiment 2

[0039]The composite fermentation bacterial agent of this embodiment is made up of 50% beneficial bacterial agent A and 50% nutritional additive B according to the mass fraction ratio; Green non-sulfur bacteria, 15% saccharomyces BGWW23202, 15% Lactobacillus acidophilus ACCC11073, 25% Pseudomonas ATCC31554, 10% Streptomyces ACCC40001; nutritional additive B is composed of % corn flour by mass fraction , 20% rice husk powder, 20% sucrose, 10% dipotassium hydrogen phosphate, and 15% sodium chloride.

[0040] Note: The total number of viable bacteria per milliliter of each microorganism is 1~5*10 8 indivual.

[0041] Usage and dosage: ferment according to the usage ratio of 1-3‰.

[0042] Storage conditions: The bacteria content per gram of bacterial agent is not less than 10 8 , stored away from light, the shelf life is 2 years, and the decomposition temperature is 65°C-72°C.

Embodiment 3

[0044] The composite fermentation bacterial agent of this embodiment is made up of 80% beneficial bacterial agent A and 20% nutritional additive B according to the mass fraction ratio; Green non-sulfur bacteria, 15% yeast BGWW23202, 15% Lactobacillus acidophilus ACCC11073, 25% Pseudomonas ATCC31554, 10% Streptomyces ACCC40001; nutritional additive B consists of 35% corn by mass fraction powder, 20% rice husk powder, 20% sucrose, 10% dipotassium hydrogen phosphate, and 15% sodium chloride.

[0045] Note: The total number of viable bacteria per milliliter of each microorganism is 1~5*10 8 indivual.

[0046] Usage and dosage: ferment according to the usage ratio of 1-3‰.

[0047] Storage conditions: The bacteria content per gram of bacterial agent is not less than 10 8 , stored away from light, the shelf life is 2 years, and the decomposition temperature is 65°C-72°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com