Method for simply preparing amorphous alloy CuB23 nano short tube and application thereof

A technology of amorphous alloy and nano short tube, which is applied in the direction of nanotechnology, can solve the problem of not using amorphous Cu-B alloy to catalyze the Heck reaction, and achieve the effect of safe use, high catalytic efficiency and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Amorphous alloy CuB 23 The preparation and application of short nanotubes mainly include the following steps:

[0041] 1) Add 40 mL of 25% NH 3 ·H 2 O solution was added 10mL copper acetate solution (0.0085mol) to obtain Cu(NH 3 ) 4 2+ Complex;

[0042] 2) Then add 32mL of 1.0MKBH in an argon protective atmosphere at a temperature of 298K 4 Aqueous solution and 0.003M polyethylene glycol;

[0043]3) After turning on the plasma reaction for 5 minutes, the target product is obtained;

[0044] 4) The product is first washed once with deionized water, and then washed three times with absolute ethanol;

[0045] 5) Store it in ethanol solution until use;

[0046] 6) The prepared product is used to catalyze the Heck crosslinking reaction of cyclohexane iodide and methyl ketene.

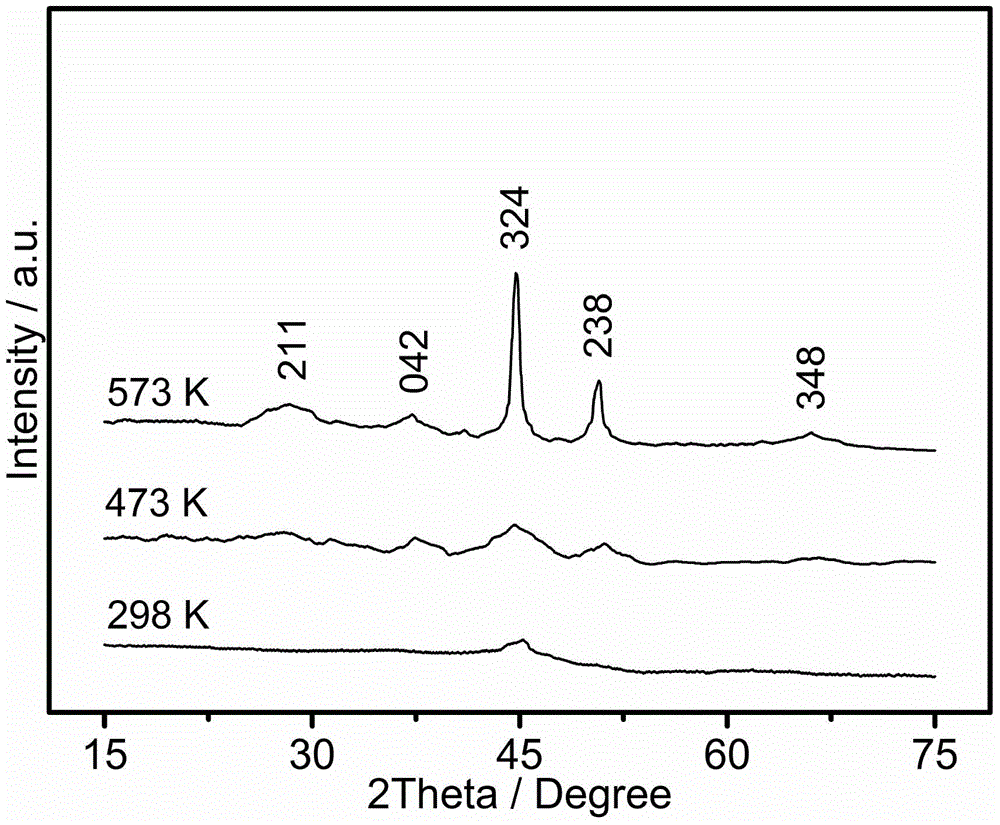

[0047] figure 1 For the prepared CuB 23 The XRD pattern of the short nanotube, it can be seen that the prepared CuB 23 The nanotubes are poorly crystalline, confirming the conclusion that...

Embodiment 2

[0055] 1) Add 40 mL of 25% NH 3 ·H 2 O solution was added 10mL copper acetate solution (0.0085mol) to obtain Cu(NH 3 ) 4 2+ Complex;

[0056] 2) Then add 32mL of 1.0MKBH in an argon protective atmosphere at a temperature of 298K 4 Aqueous solution and 0.003M polyethylene glycol;

[0057] 3) After turning on the plasma reaction for 10 minutes, the target product was obtained;

[0058] 4) The product is first washed once with deionized water, and then washed three times with absolute ethanol;

[0059] 5) Store it in ethanol solution until use;

[0060] 6) The prepared product is used to catalyze the Heck crosslinking reaction of cyclohexane iodide and acrylonitrile. Example 3

Embodiment 3

[0061] 1) Add 40 mL of 25% NH 3 ·H 2 O solution was added 10mL copper acetate solution (0.0085mol) to obtain Cu(NH 3 ) 4 2+ Complex;

[0062] 2) Then add 32mL of 1.0MKBH in an argon protective atmosphere at a temperature of 298K 4 Aqueous solution and 0.003M polyethylene glycol;

[0063] 3) After turning on the plasma reaction for 20 minutes, the target product was obtained;

[0064] 4) The product is first washed once with deionized water, and then washed three times with absolute ethanol;

[0065] 5) Store it in ethanol solution until use;

[0066] 6) The prepared product is used to catalyze the Heck crosslinking reaction of cyclopentane iodide and methyl ketene.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average length | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com