Phase change energy storage fiber with isolation cavities as well as preparation method of phase change energy storage fiber

A technology of phase change energy storage and isolation cavity, which is applied in the fields of fiber chemical characteristics, rayon manufacturing, textiles and paper making, etc. It can solve the problems of low latent heat of phase change, uneven distribution, poor controllability, etc., and achieve excellent temperature regulation performance , Improve mechanical properties, good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

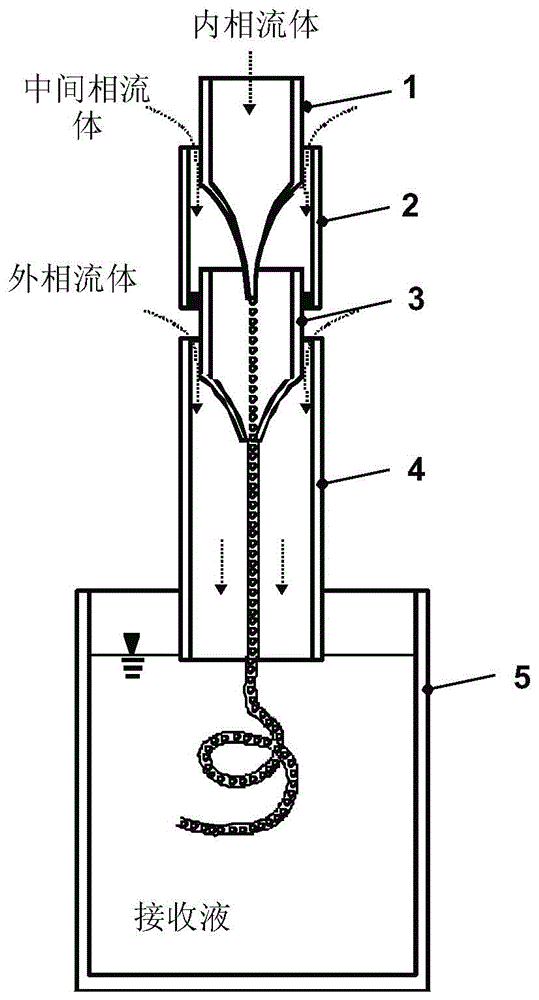

Method used

Image

Examples

Embodiment 1

[0049] In this example, the preparation method of the phase change energy storage fiber with isolated chamber is as follows:

[0050] (1) Preparation of intermediate phase fluid, external phase fluid and receiving liquid

[0051] Prepare interphase fluid: Dissolve boric acid in deionized water at normal pressure and room temperature to form boric acid aqueous solution, adjust the pH value of boric acid aqueous solution to 4.0-4.2 with acetic acid aqueous solution with a pH value of 2, add polyvinyl alcohol 1799 washed with water and juxtapose Stir in a water bath at 90-95°C for 3 hours, polyvinyl alcohol 1799 is completely dissolved to form a mixed solution, and then the mixed solution is left to stand in a water bath at 90-95°C for 1 hour, and the air bubbles in it have been completely removed to obtain a mesophase fluid ; The mass ratio of polyvinyl alcohol to deionized water is 0.1:1, and the mass ratio of boric acid to polyvinyl alcohol is 0.03:1.

[0052] Prepare the ext...

Embodiment 2

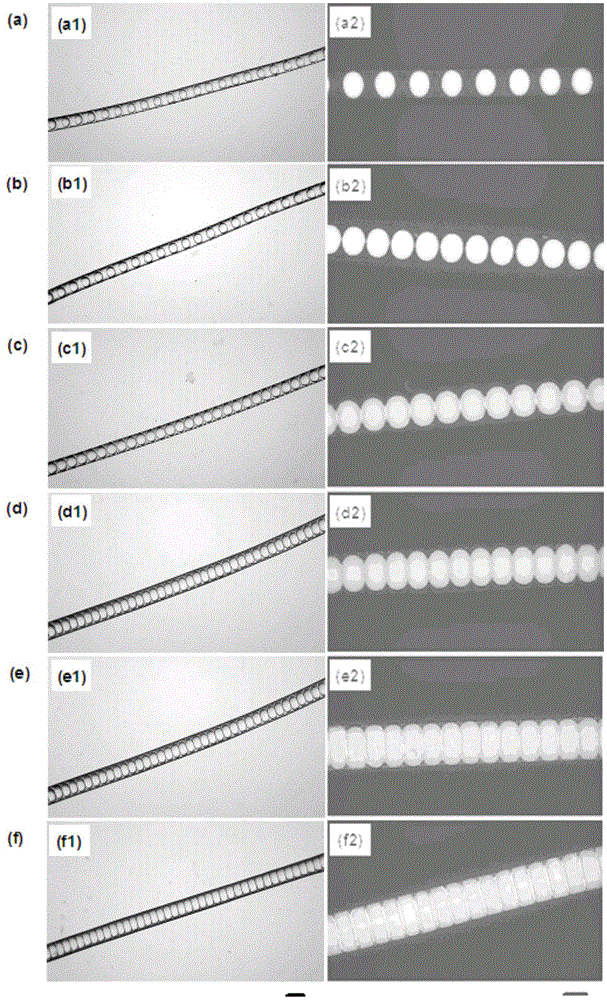

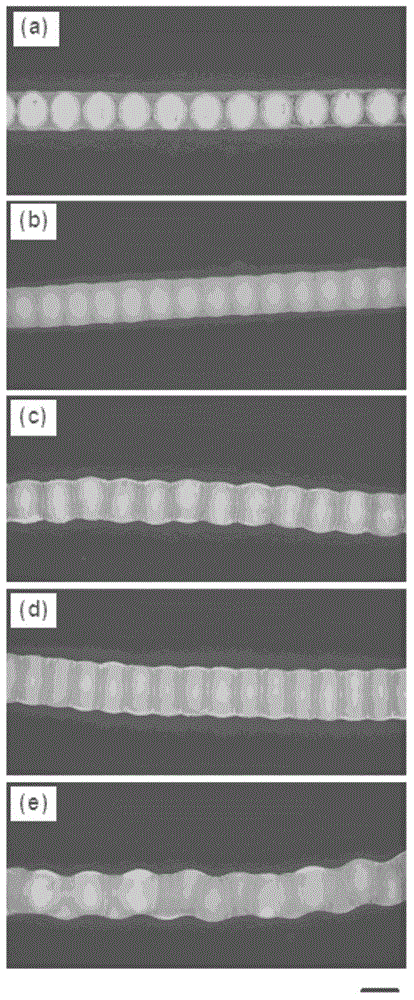

[0060] In this example, the preparation method of the phase change energy storage fiber is basically the same as that in Example 1, except that the flow rate of the internal phase fluid in step (2) is 8 μL / min, and the prepared phase change energy storage fiber contains RT27 The content is 40.39wt.%.

Embodiment 3

[0062] In this example, the preparation method of the phase change energy storage fiber is basically the same as that of Example 1, except that the flow rate of the internal phase fluid in step (2) is 12 μL / min, and the prepared phase change energy storage fiber contains RT27 The content is 50.41wt.%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| phase transition enthalpy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com