Crystal silicon solar cell high adhesive force back surface field aluminum electrocondution slurry and preparation method

A technology of solar cells and conductive pastes, applied in the manufacture of cables/conductors, conductive materials dispersed in non-conductive inorganic materials, circuits, etc., can solve problems such as bending of silicon wafers and component processes that affect solar cell yields, and achieve Substrate deformation is small, the appearance is good, and the effect of strong adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5

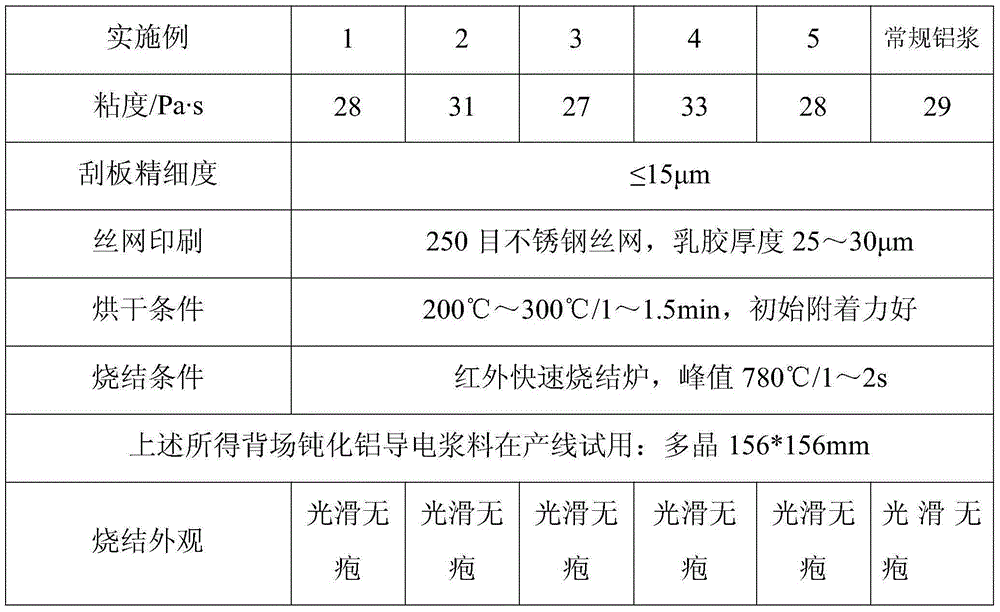

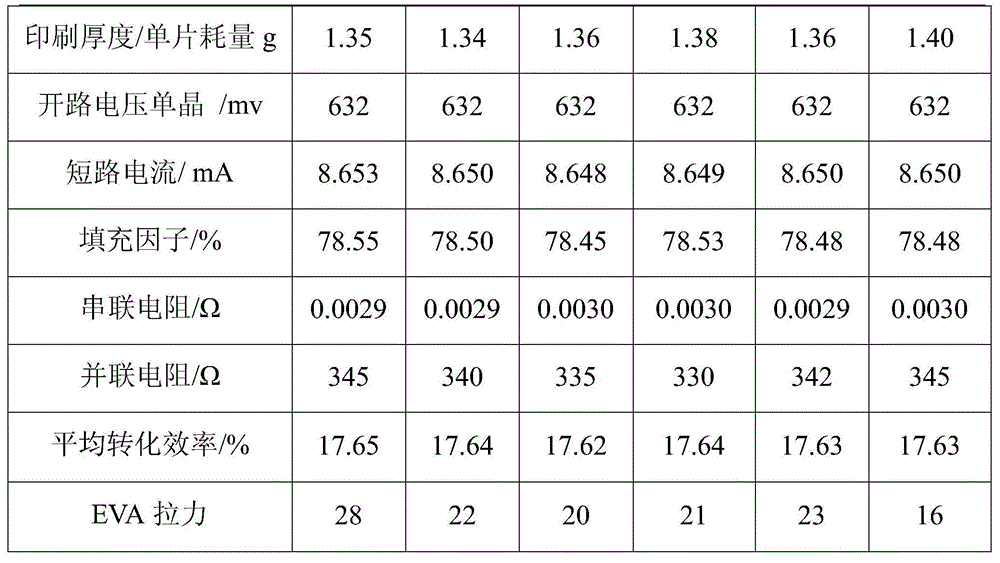

[0024] A crystalline silicon solar cell high-adhesion back-field aluminum conductive paste, the aluminum conductive paste is formed by mixing the raw materials shown in Table 1 below (by mass percentage).

[0025] Table 1. Details of the composition of the aluminum conductive paste in Examples 1 to 5

[0026] Example

1

2

3

4

5

Aluminum powder

68

75

71

80

78

glass powder

6

4

3

1

2

organic binder

25

19

24.5

16

17.5

Auxiliary

1

2

2.5

3

2.5

[0027] The preparation method of the high-adhesion back-field aluminum conductive paste for crystalline silicon solar cells is as follows: put the raw material aluminum powder, silicon-aluminum alloy powder, glass powder and organic adhesive into a vacuum mixer according to the proportions in Table 1 above , continue to stir for about 2 hours to form a uniform mixture, then disperse through a three-ro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com