Multiple-response polymer microsphere drug carrier material and a preparation method thereof

A multi-response, polymer technology, used in pharmaceutical formulations, wave energy or particle radiation treatment materials, inactive components of polymer compounds, etc., can solve the problems of single response factors and inability to meet

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

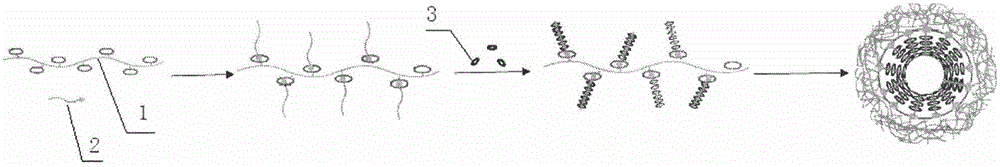

[0022] As shown in Figure 1, weigh 100 mg of sodium alginate grafted β-cyclodextrin (Alg-β-CD, β-CD grafting rate of 18.1%) to prepare a 0.6% solution, and add a corresponding amount of monomethyl Ether polyethylene glycol single-end modified ferrocene (PEG-Fc, conversion rate 95.4%), the concentration is 0.5%. Alg-β-CD and PEG-Fc were mixed (β-CD:Fc=1:1). Stir at room temperature for 3h, so that β-CD and Fc fully inclusion. Subsequently, excess α-CD was added with a concentration of 6%, and the stirring was continued for 12 hours. The system gradually changed from clear to turbid, and polymer microspheres were formed. This system can respond to oxidizing agents, and the microspheres disintegrate. Among them, when 0.1ml of hydrogen peroxide is added to the microsphere system, it can be found that the visible light transmittance of the system increases from 5% to 98.1% within 5 minutes, indicating that most of the microspheres have disintegrated. At the same time, when the s...

Embodiment example 2

[0024] Weigh 80 mg of hydroxymethyl konjac glucomannan grafted β-cyclodextrin (CKGM-β-CD, β-CD grafting rate is 20.4%) to prepare a 0.5% solution, add a corresponding amount of poly P65 single The end-modified ferrocene (P65-Fc, the conversion rate is 96.6%), its concentration is 0.55%. CKGM-β-CD and P65-Fc were mixed (β-CD:Fc=1.5:1). Stir at room temperature for 4 h, so that β-CD and Fc fully inclusion. Subsequently, excess α-CD was added with a concentration of 7%, and the stirring was continued for 12 hours. The system gradually changed from clear to turbid, and polymer microspheres were formed. Add 0.05ml of sodium hypochlorite to the system, and after stirring for 10 minutes, the light transmittance of the system rises from 5% to 96.3%, indicating that most of the microspheres have disintegrated. If the electrode is inserted into the microsphere system and a direct current of 6V is applied, the visible light transmittance of the system can reach 95.9% after 3 hours, ind...

Embodiment example 3

[0026]Weigh 150 mg of polyacrylic acid-polymethacrylic acid copolymerized grafted β-cyclodextrin (PAA-co-PMAA-β-CD, β-CD graft rate 17.2%) to prepare a 0.8% solution, add the corresponding amount The polyether P123 single-end modified ferrocene (P123-Fc, the conversion rate is 97.1%), its concentration is 0.65%. PAA-co-PMAA-β-CD and P123-Fc were mixed (β-CD:Fc=2:1). Stir at room temperature for 6h, so that β-CD and Fc fully inclusion. Subsequently, excess α-CD (concentration: 9%) and 10 mg / ml glucose oxidase GOD were added, and the stirring was continued for 6 hours. The system gradually changed from clear to turbid, and polymer microspheres were formed. Add 0.05ml oxidant cerium ammonium nitrate to this system, and after stirring for 10 minutes, it can be found that the visible light transmittance of the system rises from 5% to 94.7%, indicating that most of the microspheres have collapsed. If 0.5ml of saturated glucose solution is added to the microsphere system, it can be...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com