Optical energy antibacterial nano fiber composite material and application of material to air purification products

A technology of nanofibers and composite materials, applied in applications, layered products, fiber processing, etc., to achieve the effects of low energy consumption, small resistance, and avoiding secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

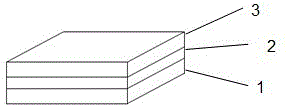

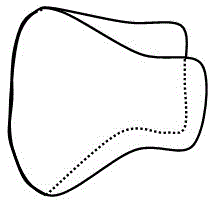

[0031] figure 1 Respectively indicate that the light-energy antibacterial nanofiber composite material is used as a filter structure. The filter is composed of 1 inner layer of non-woven fabric layer, 2 middle antibacterial layer sprayed with high-efficiency organic amino acid zinc phthalocyanine photocatalyst, and 3 outer layer of nanofibers. Composed of thermal composite filter layers, it can effectively filter PM2.5 particles up to 95%, and at the same time, under the irradiation of natural light or LED red light, high-energy oxygen is generated, which is effective against common pathogenic bacteria (including but not limited to Staphylococcus aureus, Escherichia coli and white Candida) 15 minutes - 1 hour to achieve a kill rate of 70% - 99% (such as Figure 8 shown). figure 2 The schematic diagram of the three-dimensional structure of the filter, the structure of the filter can effectively fit the human face, and can be completely fitted with the mask.

Embodiment 2

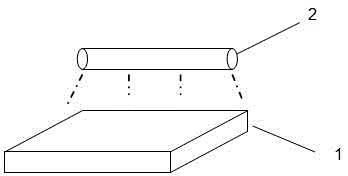

[0033] Such as image 3 As shown, a light energy antibacterial material consists of 1 antibacterial layer and 2 LED red light sources. The antibacterial layer in this combination is mainly composed of bamboo fiber fabric sprayed with high-efficiency organic amino acid zinc phthalocyanine photocatalyst. The organic amino acid zinc phthalocyanine photocatalyst on the antibacterial layer generates free or singlet oxygen under light irradiation, which can Kill super bacteria, and achieve a killing rate of 70% - 99% for common pathogens (including but not limited to Staphylococcus aureus, Escherichia coli and Candida albicans) in 15 minutes - 1 hour (such as Figure 8 As shown), it can well avoid the secondary pollution of bacteria. This kind of light energy antibacterial material is suitable for air purification products with existing filter systems.

Embodiment 3

[0035] Such as Figure 4 As shown, a light-energy antibacterial nanofiber composite material consists of 1 filter layer, 2 antibacterial layers, and 3 LED red light sources. The antibacterial layer in this combination is mainly composed of bamboo fiber fabric sprayed with high-efficiency organic amino acid phthalocyanine zinc photocatalyst. After thermal fusion technology, nanofibers with a unit weight of 0.03g are fused to bamboo fibers to form a nanofiber filter layer. . The organic amino acid zinc phthalocyanine photocatalyst on the antibacterial layer generates free or singlet oxygen under light irradiation, which can kill superbugs and is effective against common pathogenic bacteria (including but not limited to Staphylococcus aureus, Escherichia coli and Candida albicans ) 15 minutes - 1 hour to achieve a kill rate of 70% - 99% (such as Figure 8 Shown), can well avoid the secondary pollution of bacteria. At the same time, the filter material of this structure can fil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistance | aaaaa | aaaaa |

| Resistance | aaaaa | aaaaa |

| Resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com