Hydrogen preparation method

A technology of mixed gas and biogas, applied in the field of hydrogen production, can solve the problems of high cost, waste of resources, complicated operation, etc., and achieve the effects of low cost, resource saving and wide sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

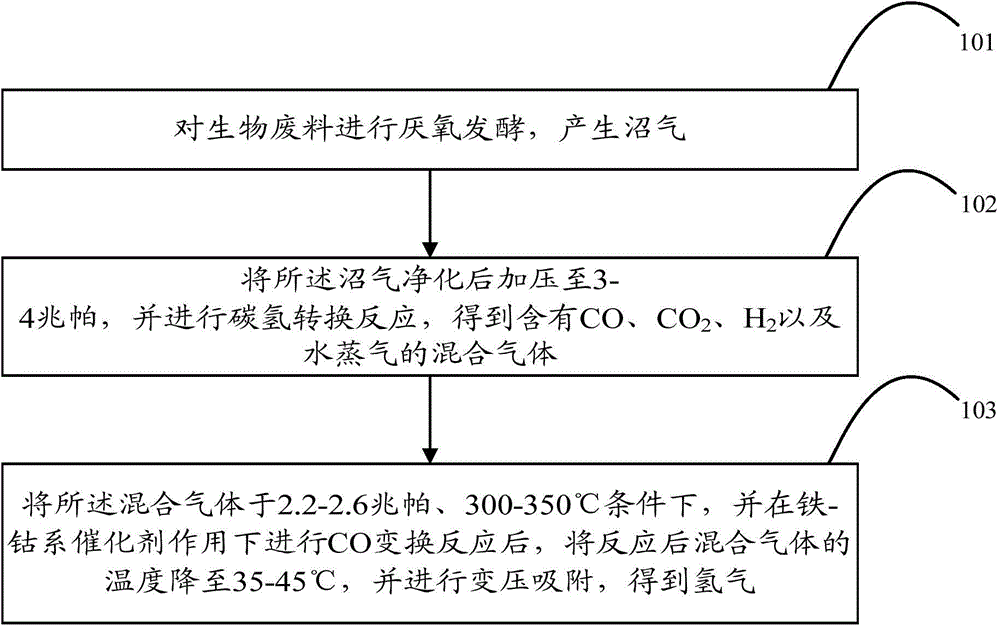

[0071] S11: Anaerobic fermentation of biological waste to generate biogas;

[0072] Biological waste includes: plant straw, livestock manure, landfill gas and organic sewage from production and domestic use.

[0073] S12: Use Thiobacillus thiooxidans to desulfurize the biogas, and then use a compressor to increase the pressure of the biogas to 3.5 MPa;

[0074] S13: Perform pressure swing adsorption to remove CO from the boosted biogas at room temperature 2 , and then carry out steam shift reaction in the reformer at 850°C under the nickel-based catalyst to obtain 2 、H 2 and a mixture of water vapor;

[0075] Wherein, in the process of the steam shift reaction, the water-to-carbon ratio is 2.5-3 (mol).

[0076] The chemical reaction that takes place in this step is:

[0077] CH 4 +H 2 O=CO+3H 2 -Q, or CO+H 2 O(g)=CO 2 +H 2 +Q.

[0078] S14: After the mixed gas is subjected to a CO shift reaction under the condition of 2.4 MPa and 320°C under the action of an iron-c...

Embodiment 2

[0082] S21: Anaerobic fermentation of biological waste to generate biogas;

[0083] Biological waste includes: plant straw, livestock manure, landfill gas and organic sewage from production and domestic use.

[0084] S22: Use Thiobacillus thiooxidans to desulfurize the biogas, and then use a compressor to increase the pressure of the biogas to 3.5 MPa;

[0085] S23: Put the boosted biogas at 700°C with Ni-Al 2 o 3 / SiO 2 As a catalyst for carbon dioxide reforming reaction of methane to obtain CO, CO 2 、H 2 and a mixture of water vapor;

[0086] The chemical reaction that takes place in this step is: CH 4 +CO 2 =2CO+2H2 .

[0087] S24: After the mixed gas is subjected to a CO shift reaction under the condition of 2.4 MPa and 320°C under the action of an iron-cobalt catalyst, the temperature of the reacted mixed gas is lowered to 40°C, and pressure swing adsorption is performed, Hydrogen with a purity greater than 99.9% is obtained.

[0088] The chemical reaction in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com