System and method for treating haze by flue gas dried sludge

A technology for drying sludge and flue gas, which is applied in dehydration/drying/concentration sludge treatment, chemical instruments and methods, sludge treatment through temperature control, etc., can solve problems such as energy consumption bottlenecks, and improve heat utilization rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

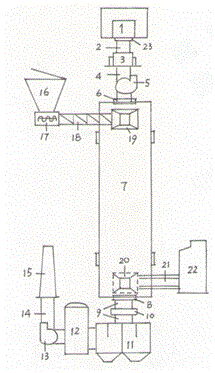

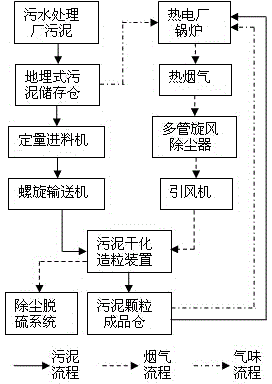

[0032] Sewage treatment plant sludge with a water content of 82% of the total weight (moisture content) is sent to a volume of 60m by a closed sludge conveyor 3 For the buried sludge storage bin, open the cover above the buried sludge storage bin, discharge the sludge into the storage bin, and then close the cover.

[0033] The flue gas discharged from the thermal power plant boiler with a temperature of 150°C passes through a multi-tube cyclone dust collector to remove 85% of the particulate matter (PM10) with a particle size greater than 10 microns in the flue gas, and then sends it into the flue gas with a diameter of 3.0m and a length of In the 28m sludge drying and granulation integrated device, the flue gas flow rate is controlled by an electric gate valve to 1.5×10 5 m / h, at the same time, start the double-screw quantitative sludge feeding machine at the bottom of the buried sludge storage bin, divide the sludge into small pieces, and use the screw conveyor to evenly an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com