Transparent, high-hardness and yellowing-resistant epoxy ornament glue and preparation process thereof

A preparation process and high hardness technology, applied in the direction of epoxy resin glue, adhesive, polymer adhesive additives, etc., can solve the problems of difficult procurement, insufficient curing agent performance, high price, etc., and achieve low cost, yellowing resistance, etc. Excellent performance and long operating time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

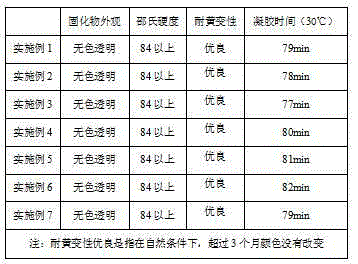

Examples

Embodiment 1

[0015] Preparation of glue A: 70 parts ("part" is the weight ratio unit, which means any unit weight. For example, each part = 100 grams, 1 kilogram or 100 kilograms, etc., the same below) epoxy resin 127, 28 parts of benzyl alcohol and 2 parts of polymethyl methacrylate and 1 part of nano-titanium dioxide are poured into a blending kettle and stirred for 10-15 minutes to prepare; among them, nano-titanium dioxide is first mixed with benzyl alcohol, stirred vigorously, heated to 70°C with microwave, and then oscillated by ultrasonic wave for 3- After 5 minutes, add to the blender.

[0016] Synthesis of glue B: Add 78 parts of diethylenetriamine and 4 parts of 1,3-cyclohexanedimethylamine into the reactor, start stirring, raise the temperature to 57°C, and add 125 parts of n-butyl glycidol dropwise within 2 hours Ether, 28 parts of phenyl glycidyl ether and 15 parts of benzyl alcohol, the reaction temperature is controlled between 60 ~ 65 ° C, after the dropwise addition, conti...

Embodiment 2

[0019] Preparation of glue A: 1. Pour 75 parts of epoxy resin 127, 23 parts of benzyl alcohol and 1.5 parts of polymethyl methacrylate, 0.5 parts of nano-titanium dioxide into the mixing tank and stir for 10-15 minutes to prepare. Among them, the nano-titanium dioxide is first mixed with benzyl alcohol, stirred vigorously, and heated to 70°C by microwave, then oscillated by ultrasonic waves for 3-5 minutes, and then added to the blending kettle.

[0020] Synthesis of glue B: Add 50 parts of diethylenetriamine and 5 parts of 1,3-cyclohexanedimethylamine into the reactor, then raise the temperature to 57°C, add 125 parts of n-butyl glycidyl ether, For the mixed solution of 50 parts of phenyl glycidyl ether and 20 parts of benzyl alcohol, control the reaction temperature between 60-65°C. After the dropwise addition, continue to keep warm for 3 hours, and use infrared spectrometer to determine the reaction end point.

[0021] Preparation of epoxy jewelry glue: 40 parts of A glue, ...

Embodiment 3

[0023] Preparation of glue A: Pour 90 parts of epoxy resin 127, 9.9 parts of benzyl alcohol and 2 parts of polymethyl methacrylate, 0.5 parts of nano-titanium dioxide into the mixing tank and stir for 10-15 minutes to prepare. Among them, the nano-titanium dioxide is first mixed with benzyl alcohol, stirred vigorously, and heated to 70°C by microwave, then oscillated by ultrasonic waves for 3-5 minutes, and then added to the blending kettle.

[0024] Synthesis of glue B: Add 100 parts of diethylenetriamine and 2.5 parts of 1,3-cyclohexanedimethylamine into the reaction kettle, then raise the temperature to 57°C, add 100 parts of n-butyl glycidyl ether dropwise within 2 hours, The mixture of 27.5 parts of phenyl glycidyl ether and 20 parts of benzyl alcohol is controlled at a reaction temperature between 70 and 75°C. After the dropwise addition is completed, the temperature is kept for 3 hours, and the end point of the reaction is determined by an infrared spectrometer.

[0025...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com