Novel thermophilic and salt-resistant strain capable of degrading raw oil and generating emulsifying agent and application thereof

A biological emulsifier, crude oil technology, applied in the fields of energy biotechnology and environmental biology, can solve the problem of not many bacterial species, and achieve the effects of strong emulsification activity, increase of saturated hydrocarbon content, and improved properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Example 1 The separation of Anoxybacillus rupiensis WJ-4 without oxygen

[0045] The screening and isolation of Anoxybacillus rupiensis WJ-4 mainly include sampling and enrichment culture, screening and purification, and identification. The specific methods are as follows:

[0046] (1) Sampling and enrichment culture

[0047] Take an appropriate amount of formation water from Longhupao oil reservoir in Daqing and insert it into the enrichment medium. The enrichment medium uses inorganic salt medium (g / L): (NH 4 ) 2 SO 4 4.5, Starch 2, Na 2 HPO 4 2.0, MgSO 4 ·7H 2 O 0.5, NaCl 1.5, FeCl 2 0.5, yeast powder 0.3, liquid paraffin 5. pH 7.2-7.5, sterilized at 121°C, cultured on a shaker at 60°C at 200rpm for 15-20 days.

[0048] (2) Screening and purification of Anoxybacillus rupiensis WJ-4

[0049] The enriched culture solution in step (1) was diluted step by step, and the dilution factor was taken as 10 4 、10 5 The bacterial solution was evenly spread on the LB ...

Embodiment 2

[0058] Example 2 Anoxybacillus rupiensis WJ-4 uses waste crude oil and molasses as carbon source to produce surfactant

[0059] The Bacillus aerobicus WJ-4 of the present invention has the property of high-yield biological emulsifier, no matter utilizes oil-soluble carbon source or water-soluble carbon source, all can synthesize biological emulsifier; Especially in industrial waste or waste (Petroleum pollution or molasses) as a carbon source for the fermentation of bioemulsifiers produced unexpected technical effects.

[0060] see Figure 4 , after the crude oil culture medium was inserted into WJ-4 cells and cultured for 10 days, the oil layer was dispersed in the water phase in fine powder form, no crude oil adhered to the bottle wall, the water phase was brownish black, the oil-water interface was unclear, and no stratification after standing still ( flask on the right in the figure). However, the water phase of the crude oil medium without bacterial cells was still clea...

Embodiment 3

[0065] Example 3 Application of Anoxybacillus rupiensis WJ-4 and its fermented liquid in degradation of crude oil

[0066] In order to study the properties of strain WJ-4 to degrade crude oil, this example uses this strain to carry out microbial degradation experiments on Daqing Longhupao crude oil, and analyzes the impact of bacterial degradation on crude oil saturated hydrocarbons, aromatics, colloids, and asphaltenes in crude oil. The influence of the relative content and internal composition, and the emulsification performance of the emulsifier formed during the degradation process on crude oil.

[0067] Surfactant Analysis

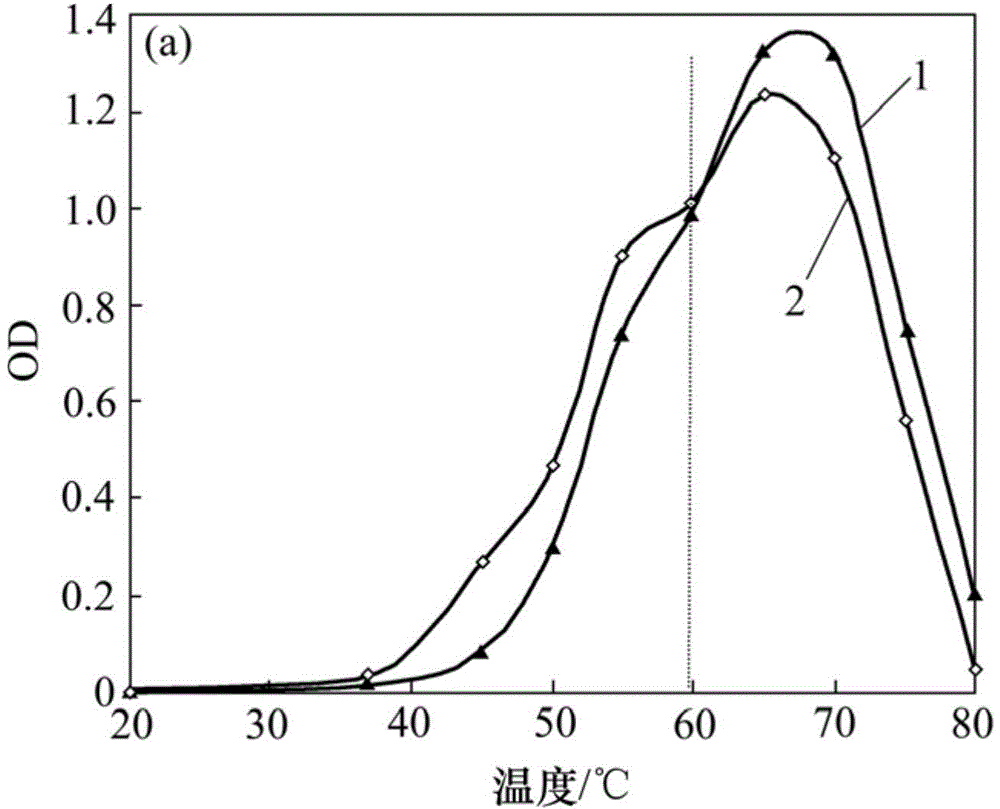

[0068] The fermentation kinetic curves of Anoxybacillus rupiensis WJ-4 strain under aerobic and anaerobic conditions using waste crude oil and molasses as carbon sources are as follows: Figure 5A and Figure 5B shown. It can be seen from the figure that Anoxybacillus rupiensis WJ-4 strain can efficiently utilize crude oil and molasses to synthesiz...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com