Method for enriching aroma components of cherry wine

A technology of aroma components and cherry wine, which is applied in the chemical industry, can solve the problems of limited adsorption capacity, high experimental cost, and difficulty in extraction, and achieve the effects of improving recovery rate, low cost, and reducing losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] 1) Take 100 mL of a commercially available kirsch (16% alcohol), add 4 g of sodium chloride, 200 μl of internal standard dioctyl alcohol, and then add dichloromethane and petroleum ether mixture (volume ratio 1:1), respectively Continuously extract 20 mL, 20 mL, and 10 mL of the mixture of methyl chloride and petroleum ether three times, combine the organic phase, centrifuge the organic phase at a speed of 5000 r / min for 15 min, discard the precipitate, and add anhydrous sodium sulfate to the organic phase to remove water , and the solution after removing water was filtered through a 0.45 μm filter membrane.

[0015] 2) Put the mixed solution obtained after membrane filtration into a distillation bottle, place it in a constant temperature water bath at 35-45°C for rectification, the solvent and a small amount of volatile components enter the rectification column and The surface of the filling material is separated, the solvent is cooled by the condenser, and the volatil...

Embodiment 2

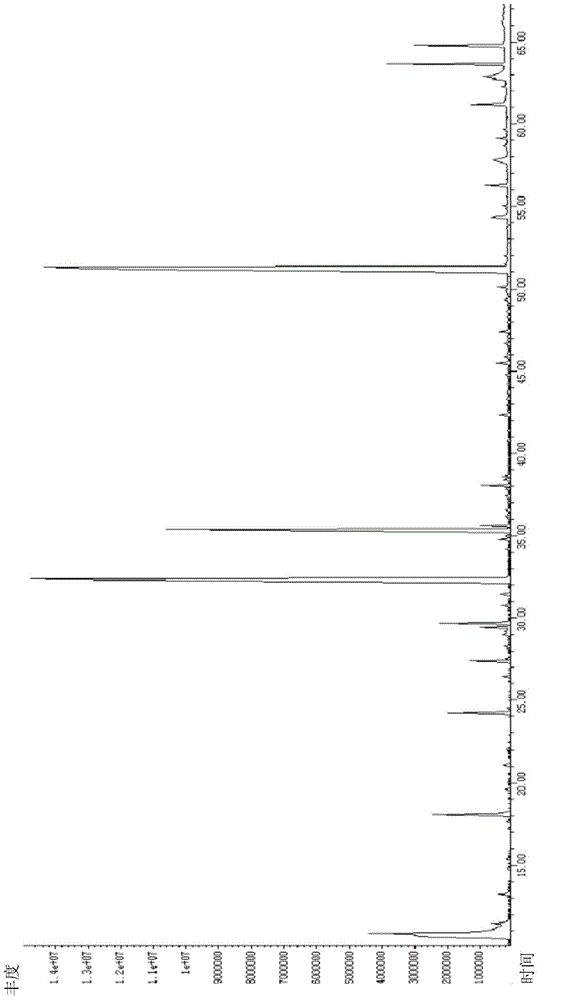

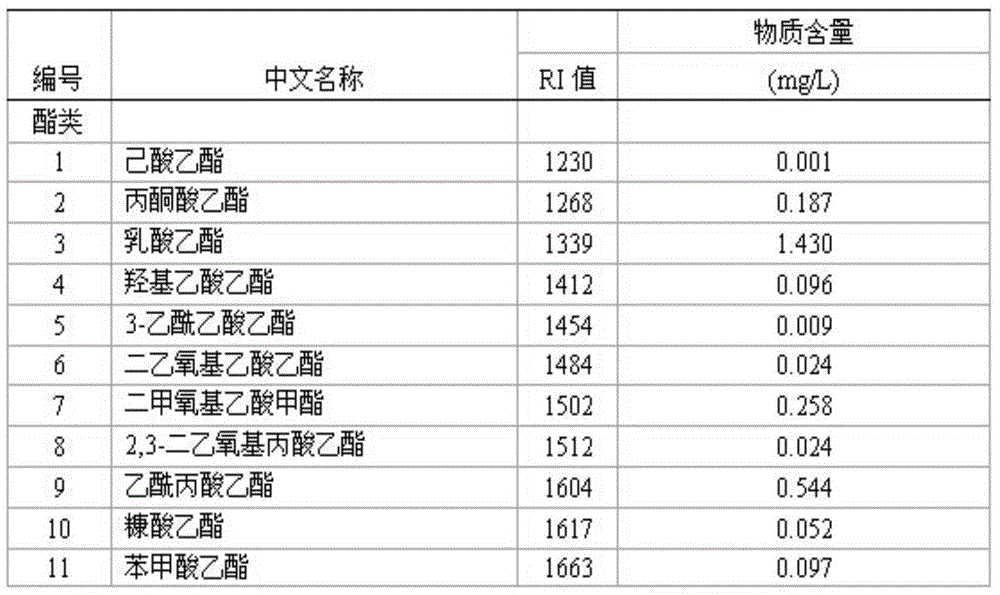

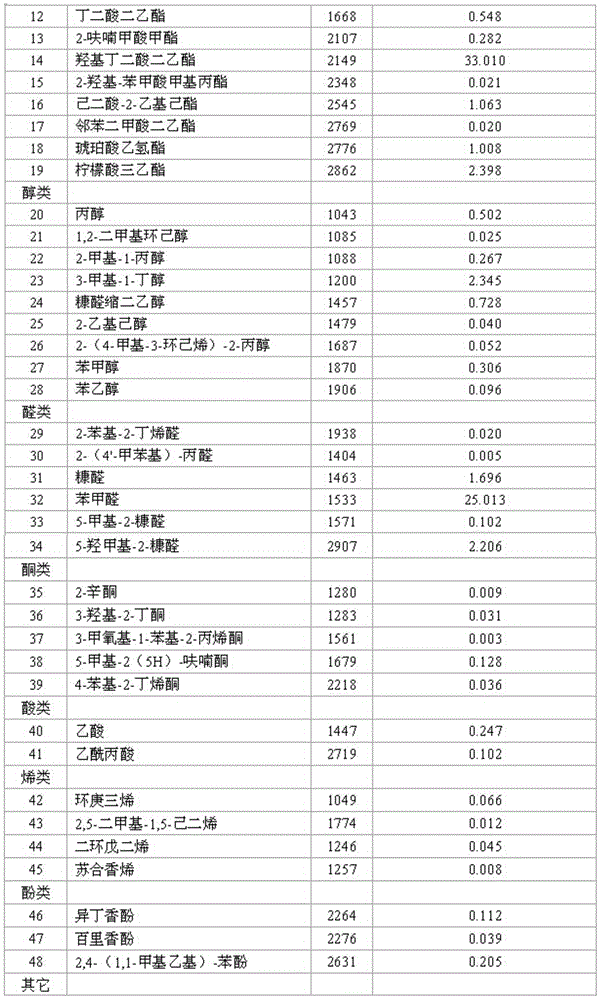

[0017] 1 μL of the concentrated solution of Example 1 was directly injected for GC-MS analysis. A7890A-5973C GC / MS was selected, and the GC conditions were as follows: the capillary chromatographic column was Agilent HP-INNOWAX (60m×250m x0.25μm), the inlet temperature was 250°C, and the temperature was programmed: the initial temperature was 40°C, retained for 2 minutes, and then increased to 3°C. / min rate increased to 230°C, hold for 2min; detector temperature 250°C; carrier gas He, flow rate 1mL / min; splitless injection; MS conditions: quadrupole temperature 150°C, ion source temperature 230°C, interface The temperature is 250°C, the EI ionization source, the electron energy is 70ev, and the scanning range is 30~450amu.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com